Signal state 1 or

edge change 0

→ 1

The NC program being executed is immediately stopped, the actual block is not

completed. Distances-to-go are

only completed after a new start. The axes and spin‐

dle are stopped. However, these are stopped in a controlled fashion.

The program status changes to stopped, the channel status changes to interrupted.

Signal state 0 or

edge change 1

→ 0

No effect

Signal irrele‐

vant for ...

Channel status reset

Program status interrupted

Special cases,

errors, ...

All axes and spindles that were not caused to move by program or program block

(e.g. axes are moved by pressing the traverse keys on the machine control panel)

are not decelerated to zero speed with "NC stop axes plus spindles".

The program is continued at the interrupted place with NC Start.

The

signal "NC stop axes plus spindles" must be pending for at least one PLC cycle.

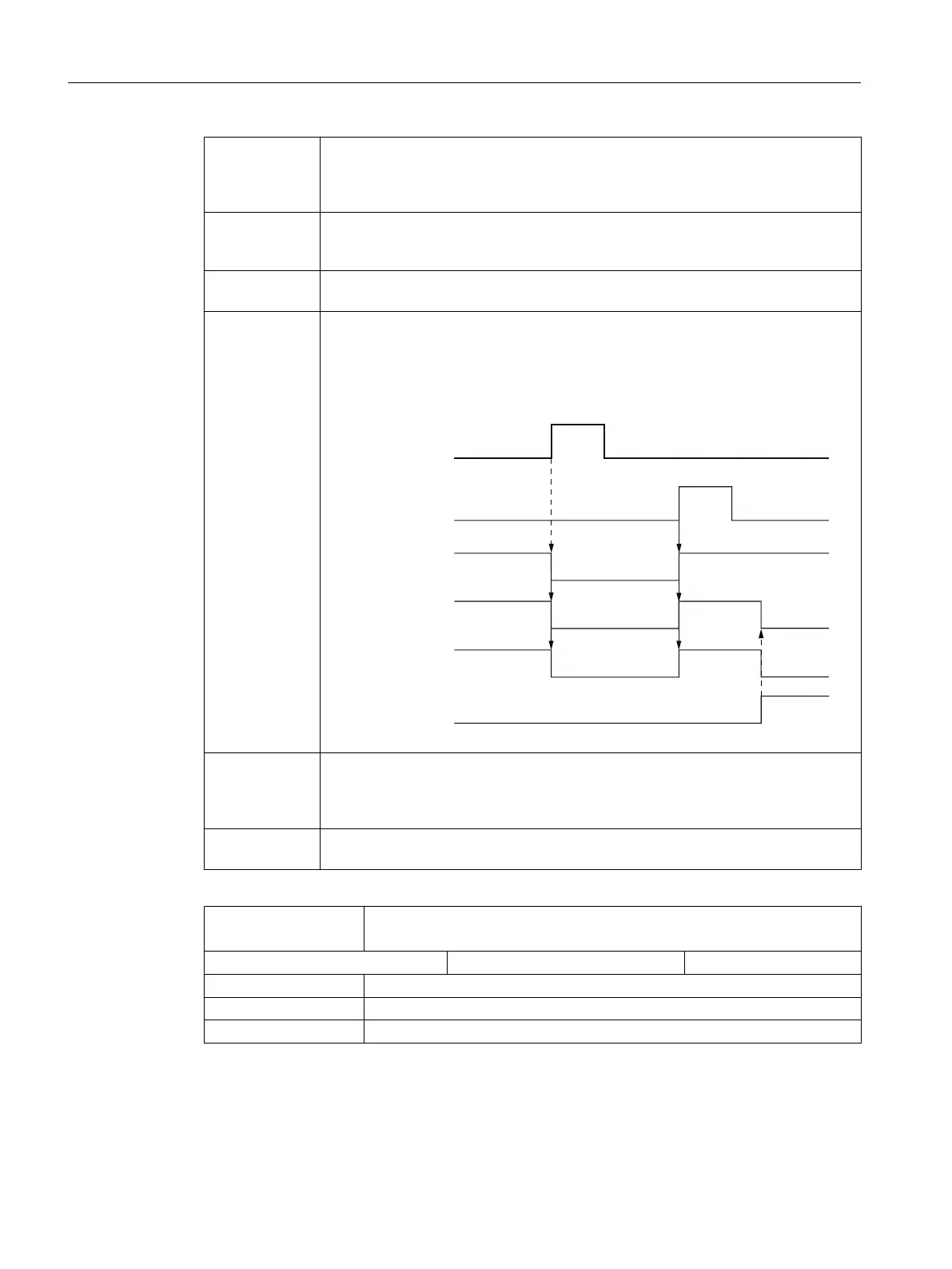

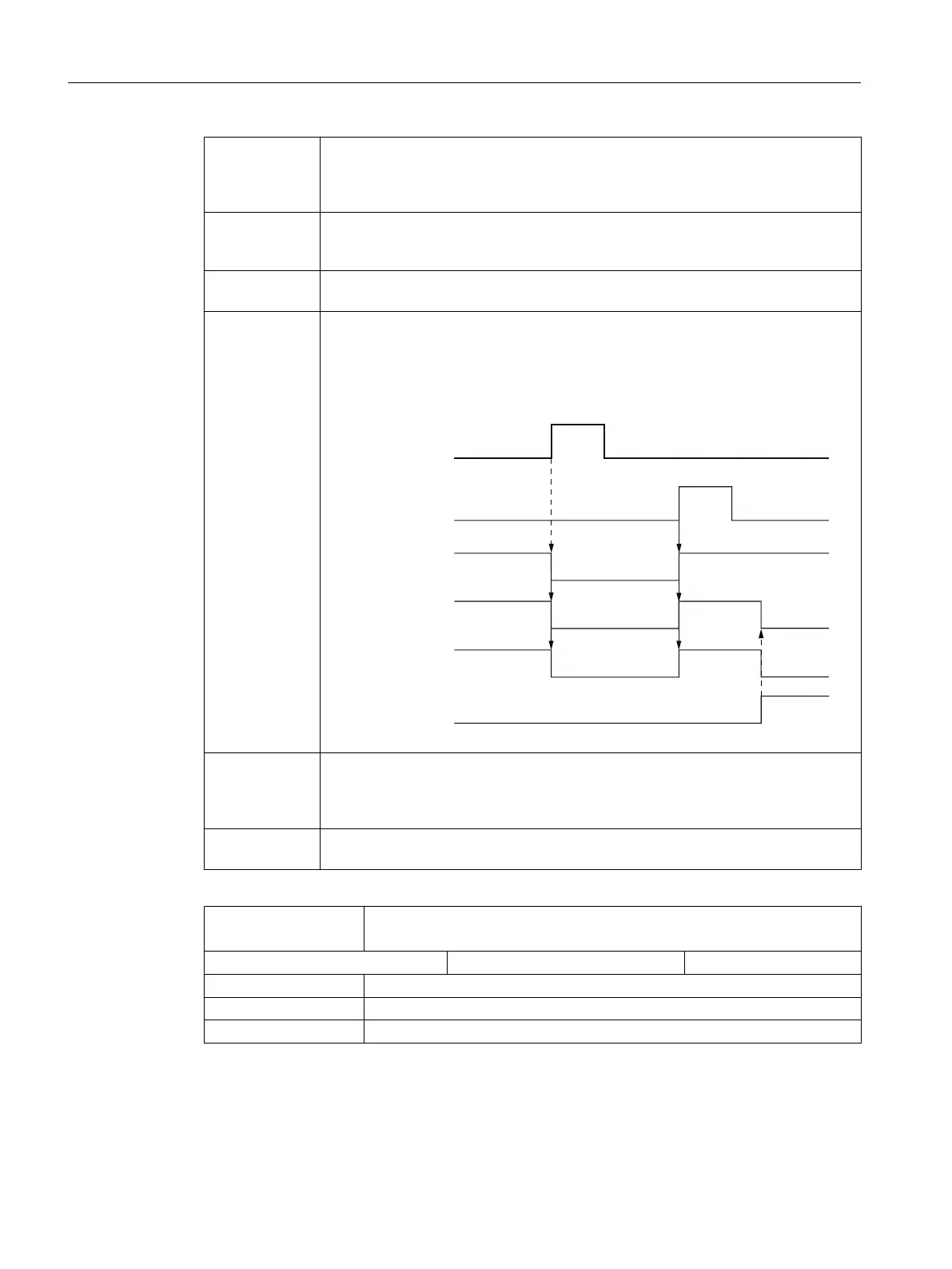

6LJQDO1&6WRSD[HV

6LJQDO1&6WDUW

3URJUDPUXQQLQJ

$[LVUXQQLQJ

6SLQGOHUXQQLQJ

%ORFNSURFHVVHG

corresponding

to ...

IS "NC stop at block limit"

IS "NC stop"

IS "Program status stopped"

IS "Channel status interrupted"

Note for the

reader

Function Manual Basic Functions K1

DB3200

DBX13.5

Deactivate workpiece counter

Signal(s) to channel (PLC → NCK)

Edge evaluation: No Signal(s) updated: Cyclic

Signal state 1 The workpiece count monitoring is deactivated with activated tool monitoring.

Signal state 0 No effect

Note for the reader Function Manual Basic Functions W1

Detailed descriptions of interface signals

5.7 Channel-specific signals

Parameter Manual

386 Parameter Manual, 08/2015, 6FC5397-8EP40-0BA1

Loading...

Loading...