the handwheels connected to

a hardware module:

0 = No handwheel configured

1..6 = Handwheel connection to HW module/Ethernet interface

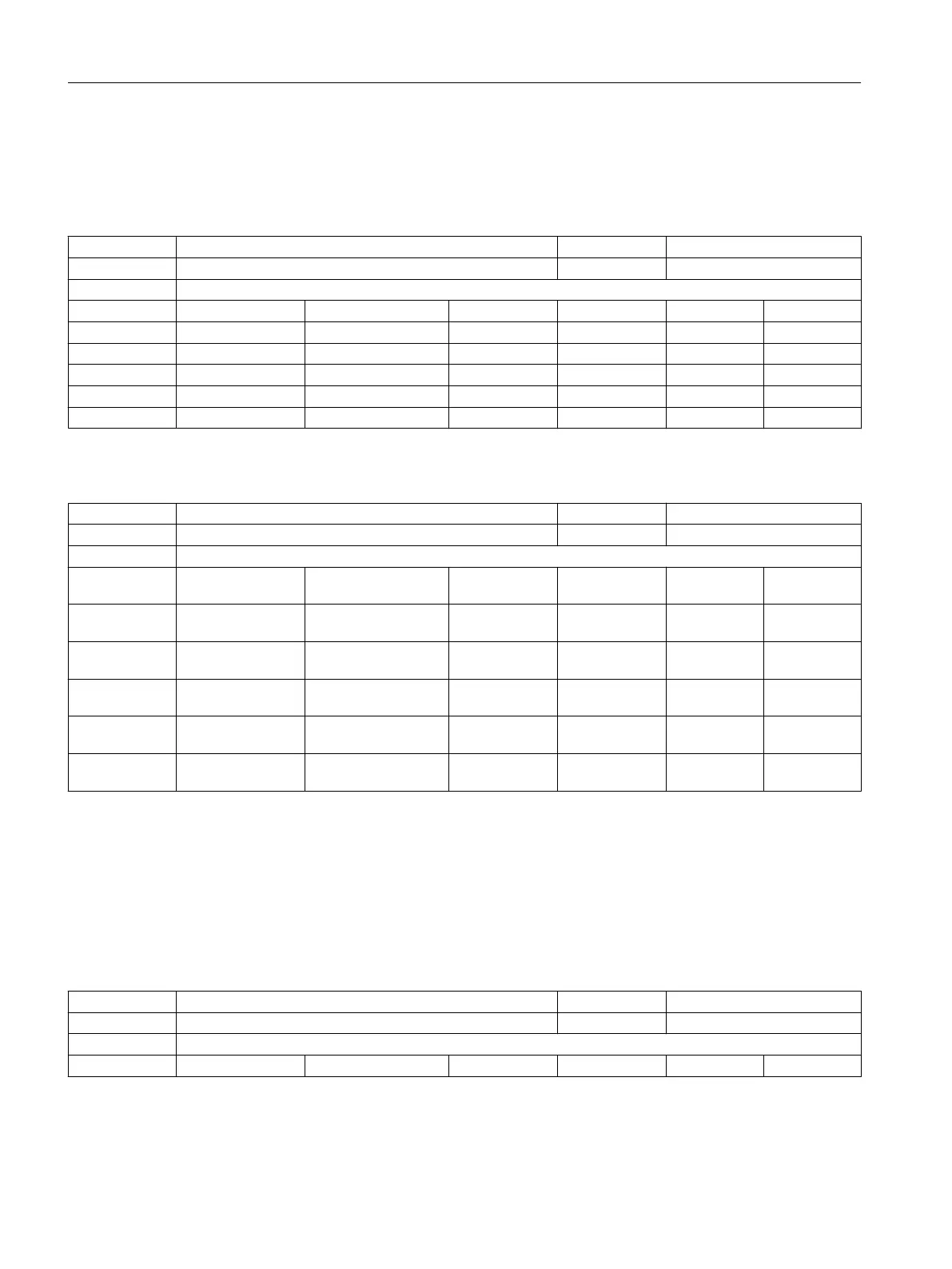

11353 HANDWHEEL_LOGIC_ADDRESS N04, N10 H1

- Logical handwheel slot addresses DWORD PowerOn

-

808d-me42 6 0, 0, 0, 0, 0, 0 0 16383 ReadOnly

808d-me62 6 0, 0, 0, 0, 0, 0 0 16383 ReadOnly

808d-te42 6 0, 0, 0, 0, 0, 0 0 16383 ReadOnly

808d-te62 6 0, 0, 0, 0, 0, 0 0 16383 ReadOnly

808d-mte40 6 0, 0, 0, 0, 0, 0 0 16383 7/2

808d-mte60 6 0, 0, 0, 0, 0, 0 0 16383 7/2

Description: For PROFIBUS/PROFINET only:

Logical start address of the hand wheel slots if handwheels are connected by PROFIBUS/

PROFINET (MD11340 $MN_HANDWHEEL_SEGMENT = 5)

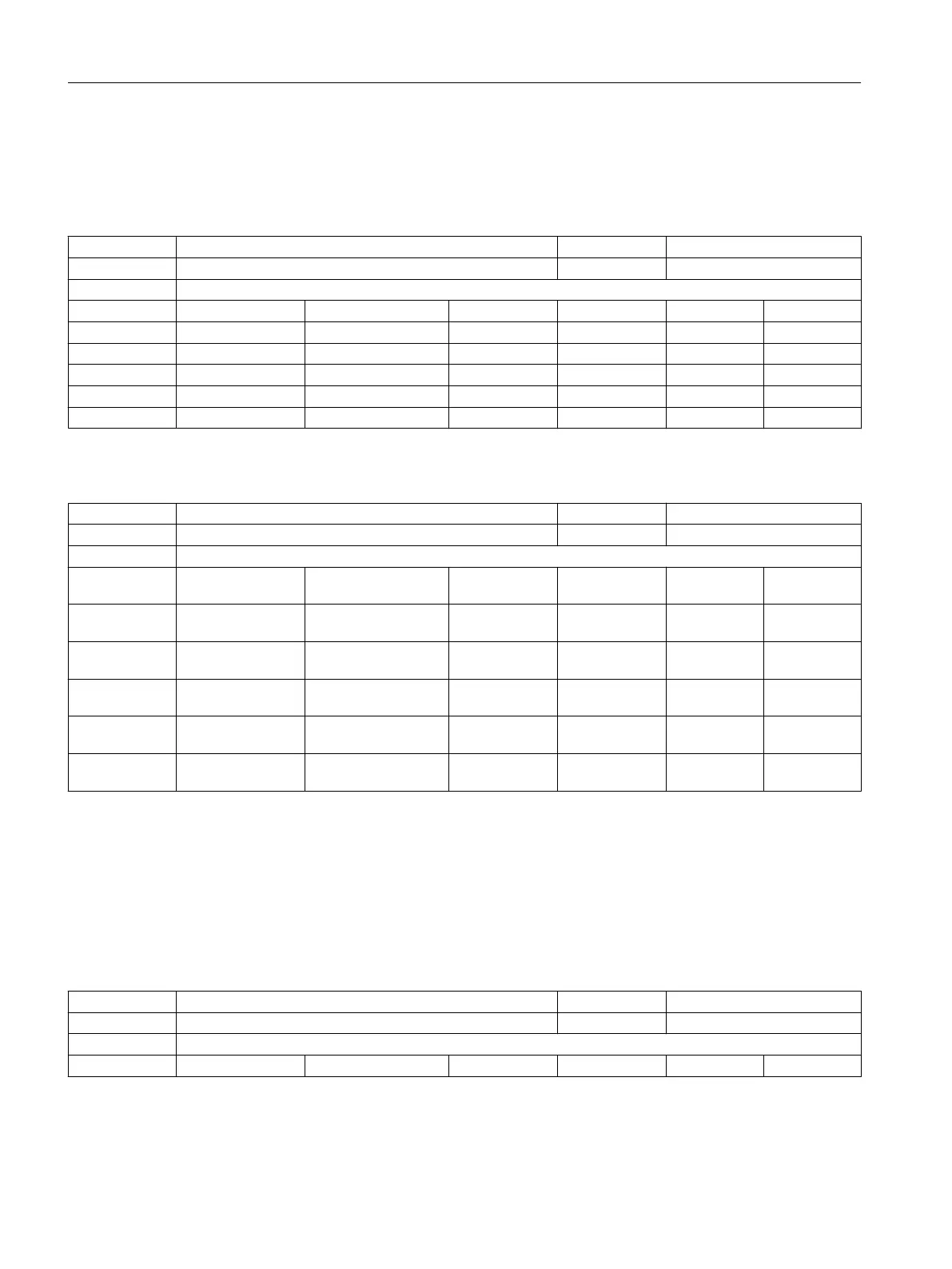

11354 HANDWHEEL_FILTER_TIME N09 -

s Filter time for handwheel pulses DOUBLE PowerOn

-

808d-me42 6 0.0, 0.0, 0.0, 0.0, 0.0,

0.0

0.0 2.0 ReadOnly

808d-me62 6 0.0, 0.0, 0.0, 0.0, 0.0,

0.0

0.0 2.0 ReadOnly

808d-te42 6 0.0, 0.0, 0.0, 0.0, 0.0,

0.0

0.0 2.0 ReadOnly

808d-te62 6 0.0, 0.0, 0.0, 0.0, 0.0,

0.0

0.0 2.0 ReadOnly

808d-mte40 6 0.0, 0.0, 0.0, 0.0, 0.0,

0.0

0.0 2.0 7/2

808d-mte60 6 0.0, 0.0, 0.0, 0.0, 0.0,

0.0

0.0 2.0 7/2

Description: The filter time indicates the time during which the pulses from the handwheel are

output to the interpolator. The values are incremented internally in interpolation

cycles.

In the case of a filter time setting = 0.0, the pulses from the handwheel are output

to

the interpolator

within a single interpolation cycle. This can cause the controlled

axis to exhibit jerk during traversing.

Machine data is valid for the following types of handwheel (see 11350

$MN_HANDWHEEL_SEGMENT):

SEGMENT_ETHERNET:

● Recommended filter time: 0.2 - 0.5 s

11450 SEARCH_RUN_MODE EXP, N01 K1, TE3, N4, H2, Z1

- Parameterization for search run DWORD PowerOn

-

- - 0x40 0 0xFF 1/1

Description: The behavior during the action blocks after block search can be affected by the

following bits:

Bit 0 = 0:

Machine data

3.2 General machine data

Parameter Manual

70 Parameter Manual, 08/2015, 6FC5397-8EP40-0BA1

Loading...

Loading...