Parameter Manual

Operating Instructions, 08/2013, 6FC5397-8EP40-0BA0

141

Machine data

2.3 Channel-specific machine data

Description: Switch on of curve and torsion smoothing.

Smoothing of the curve or torsion causes a homogenous path velocity.

Smoothing is only performed, when the relevant factor is MD 20605

$MC_PREPDYN_SMOOTHING_FACTOR > 0.

There is an entry for all dynamic G code groups.

Description: > 0: Limitation of the size of the selected increment for geometry axes

MD 11330 $MN_JOG_INCR_SIZE0[<increment/VDI signal>] or

SD41010 $SN_JOG_VAR_INCR_SIZE for geometry axes

0: No limitation on geometry axes

Description: 0: The NC/PLC interface signal DB3200 DBX7.1 (NC start) for starting part

programs or part program blocks (MDI and overstore) is active even if one or

all axes of the channel have not yet been referenced.

To ensure that the axes nevertheless reach the correct position after NC

startup, the work (workpiece coordinate system = work) must be set to the

correct value by means of other methods (scratch method, automatic work off-

set determination etc.).

1: Axes for which the axial MD34110 $MA_REFP_CYCLE_NR specifies that a ref-

erence point is mandatory (value > -1), must be referenced for NC startup to

be enabled.

2: Advanced form of setting 1 in that the axis state "Position restored"

(instead of "referenced") is sufficient for NC startup in MDI or overstore.

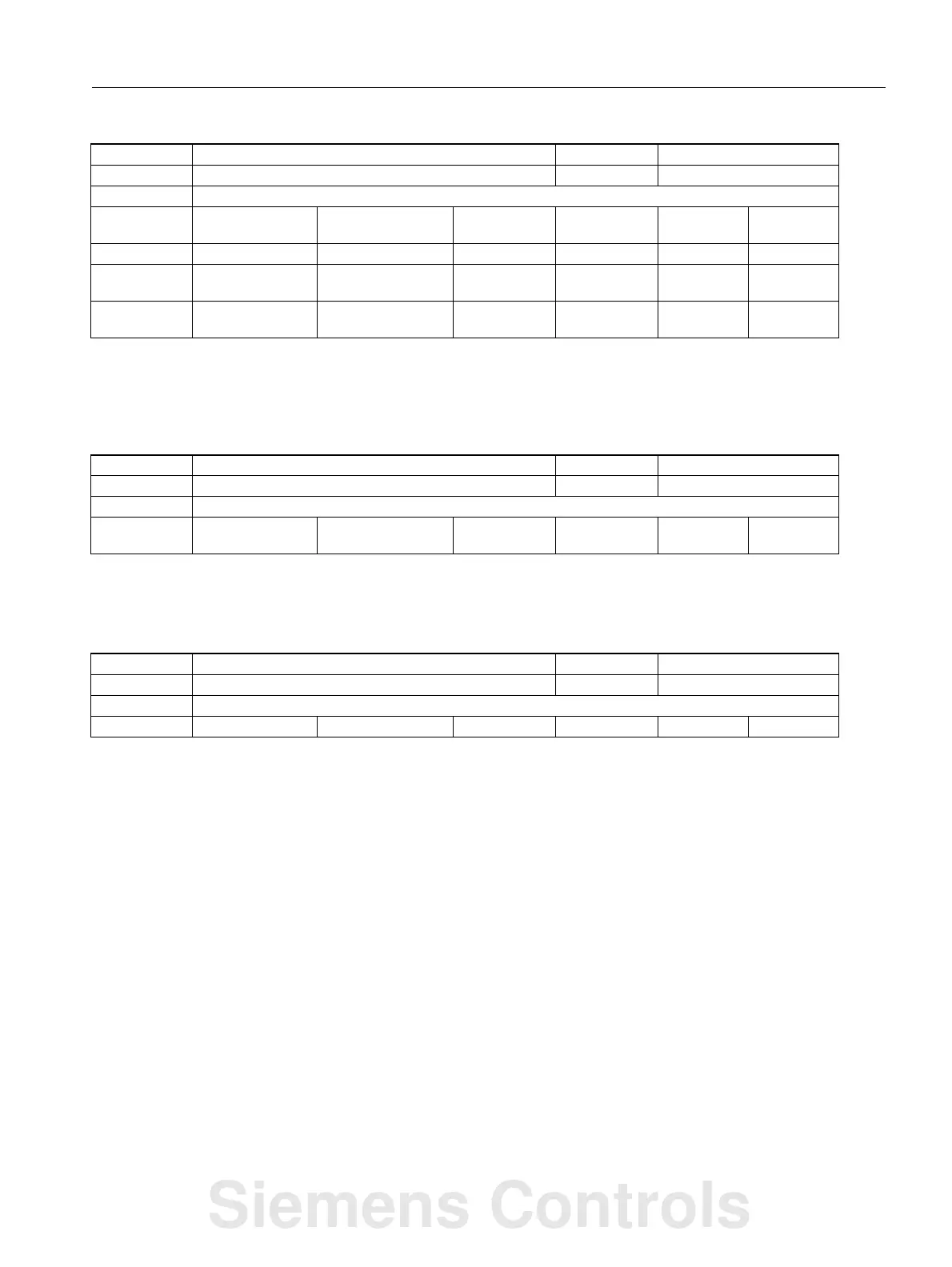

20606 PREPDYN_SMOOTHING_ON EXP, C05 B1

- Activation of curve smoothing BOOLEAN NEW CONF

-

808d-me42 5 0, 0, 0, 0, 0, 0, 0, 0,

0, 0...

0 - 1/1

808d-me62 5 0, 0, 1, 1, 1 0 - 1/1

808d-te42 5 0, 0, 0, 0, 0, 0, 0, 0,

0, 0...

0 - 0/0

808d-te62 5 0, 0, 0, 0, 0, 0, 0, 0,

0, 0...

0 - 0/0

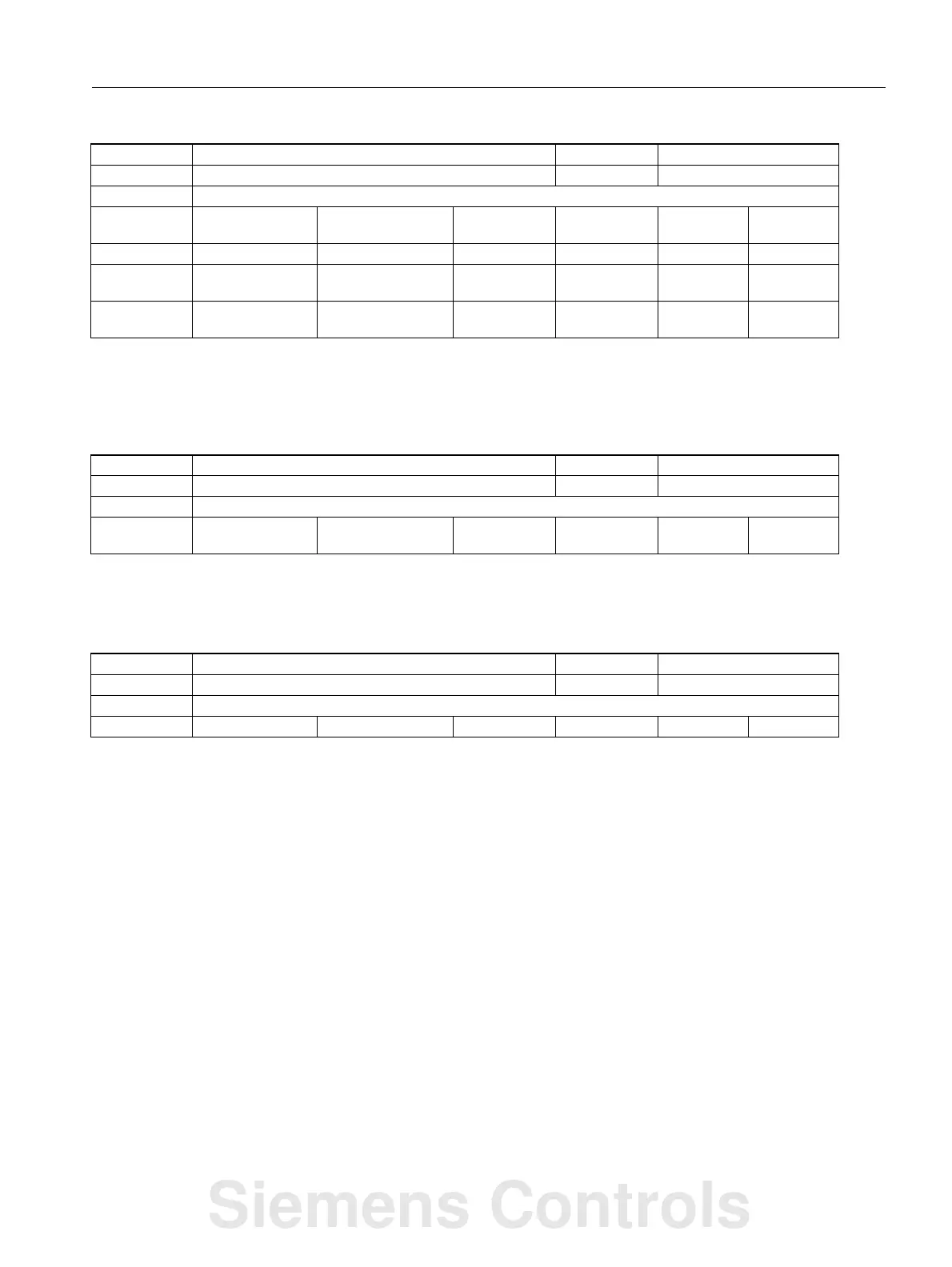

20620 HANDWH_GEOAX_MAX_INCR_SIZE C08, C06 H1

mm Limitation handwheel increment for geometry axes DOUBLE PowerOn

-

- - 0.0, 0.0, 0.0, 0.0, 0.0,

0.0, 0.0, 0.0...

0.0 - 1/1

20700 REFP_NC_START_LOCK C01, C03 D1,R1,Z1

- NC start disable without reference point BYTE Reset

-

- - 1, 1, 1, 1, 1, 1, 1, 1... 0 2 2/2

Siemens Controls

Loading...

Loading...