Parameter Manual

Operating Instructions, 08/2013, 6FC5397-8EP40-0BA0

257

Machine data

2.4 Axis-specific machine data

Description: Using low-resolution encoders, a more continuous motion of coupled path or

axis motions can be achieved with smoothed actual values. The bigger the time

constant, the better the smoothing of actual values and the larger the over-

travel.

Smoothed actual values are used for:

• Thread-cutting (G33, G34, G35)

• Revolutional feedrate (G95, G96, G97, FPRAON)

• Display of actual position and velocity, or speed respectively.

Description: Spindle definition. The spindle is defined when the spindle number has been

entered in this MD.

Example:

If the corresponding axis is to be spindle 1, value "1" must be entered in

this MD.

The spindle functions are possible only for modulo rotary axes. For this pur-

pose MD30300 $MA_IS_ROT_AX and MD30310 $MA_ROT_IS_MODULO must be set.

The axis functionality is maintained; transition to axis operation can be

performed with M70.

The gear stage-specific spindle data are set in parameter blocks 1 to 5;

parameter block 0 is used for axis operation (MD35590

$MA_PARAMSET_CHANGE_ENABLE).

The lowest spindle number is 1, the highest number depends on the number of

axes in the channel.

If other spindle numbers are to be assigned, the function "spindle converter"

must be used.

With multi-channel systems, the same numbers can be assigned in all channels,

except for those spindles active in several channels (replacement axes/spin-

dles MD 30550: $MA_AXCONF_ASSIGN_MASTER_CHAN).

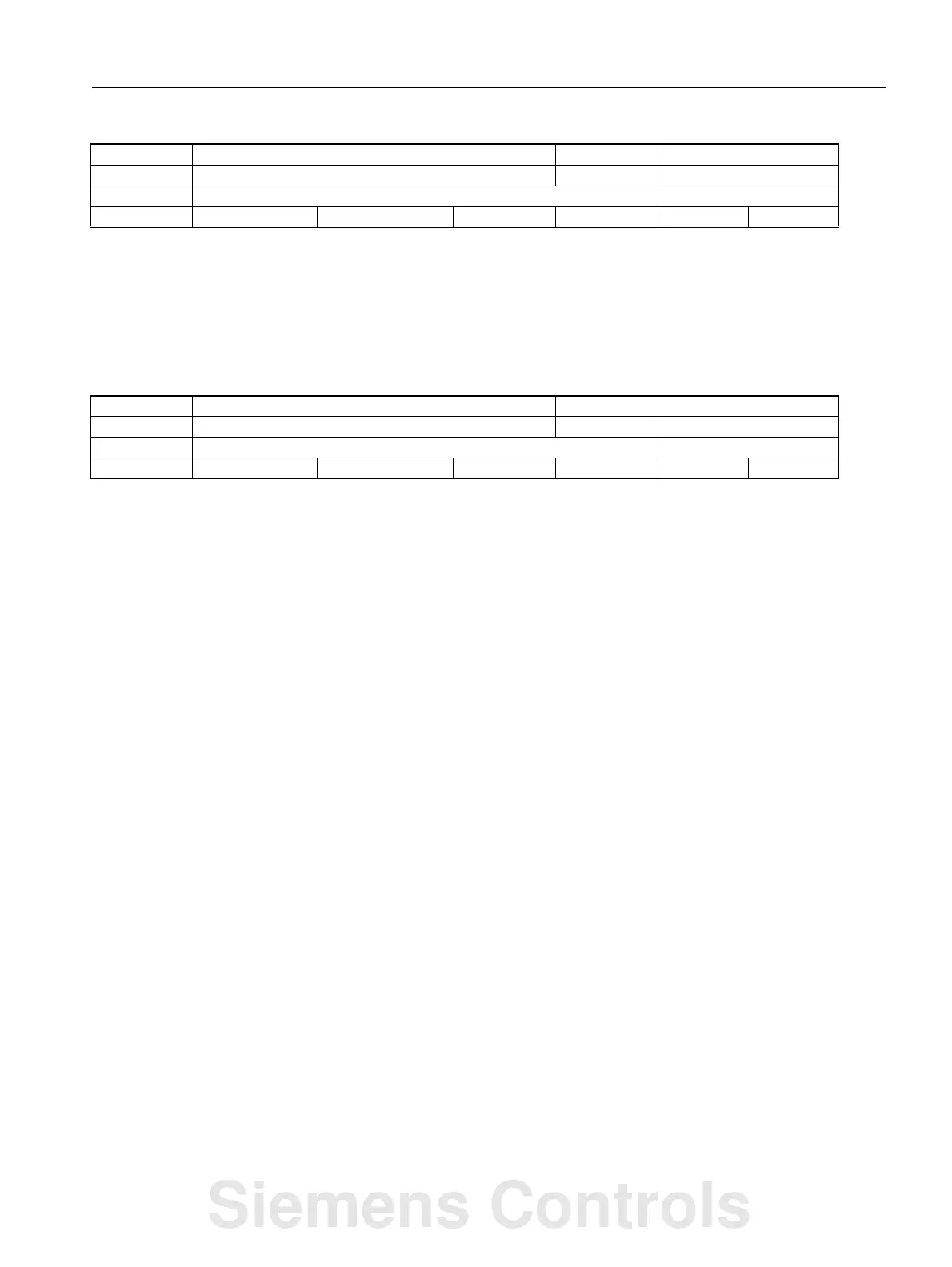

34990 ENC_ACTVAL_SMOOTH_TIME A02 V1

s Smoothing time constant for actual values. DOUBLE Reset

-

- 1 0.0, 0.0 0.0 0.5 3/3

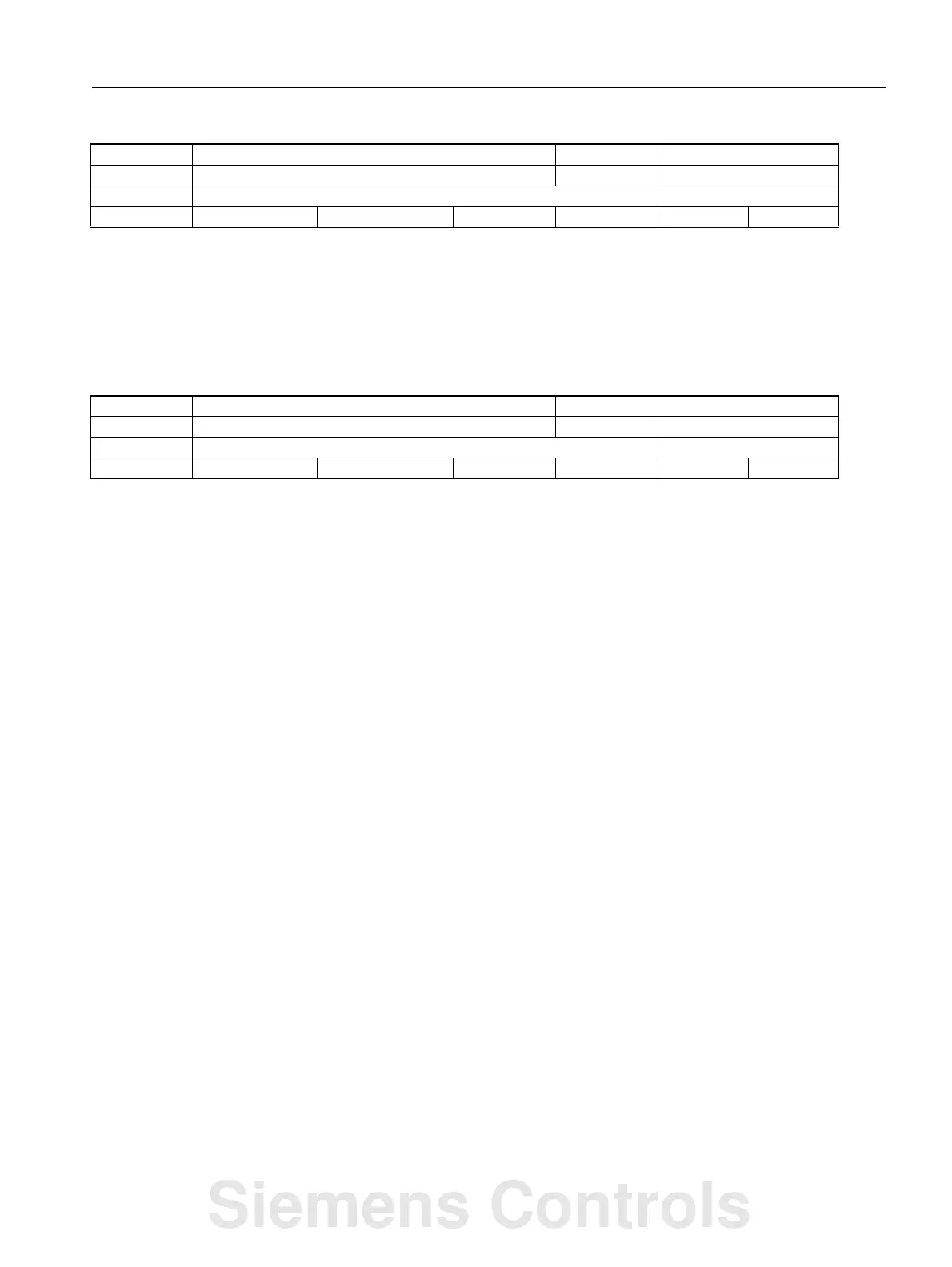

35000 SPIND_ASSIGN_TO_MACHAX A01, A06, A11 M1,S3,K2,S1

- Assignment of spindle to machine axis BYTE PowerOn

-

- - 0, 0, 0, 1 0 20 1/1

Siemens Controls

Loading...

Loading...