Parameter Manual

Operating Instructions, 08/2013, 6FC5397-8EP40-0BA0

441

PLC User Interface

5.8 Channel signals

Controls signals to axes in Work

8 Activate machine-related protection zone

Area 8 Area 7 Area 6 Area 5 Area 4 Area 3 Area 2 Area 1

9 Activate machine-related protection zone

Area 10 Area 9

10 Activate channel-specific protection zone

Area 5 Area 5 Area 5 Area 5 Area 5 Area 5 Area 5 Area 5

11 Activate channel-specific protection zone

Area 10 Area 9

12

13 Do not

block tool

Deactivate

workpiece

counter

Activate fixed feedrate

Feed 4 Feed 3 Feed 2 Feed 1

14 No tool

change

commands

JOG circle Activate

associated

M01

Negative

direction for

simulation

contour

handwheel

Simulation

contour

handwheel

ON

Activate contour handwheel (bit/binary

coded)

Handwheel

1

Handwheel

2

15 Activate

skip block 9

Activate

skip block 8

Invert

contour

handwheel

direction

16 Program

branches

(GOTOS)

control

17

18

19

1)

Select single-block type selection using the softkey.

2)

31 positions (Gray code)

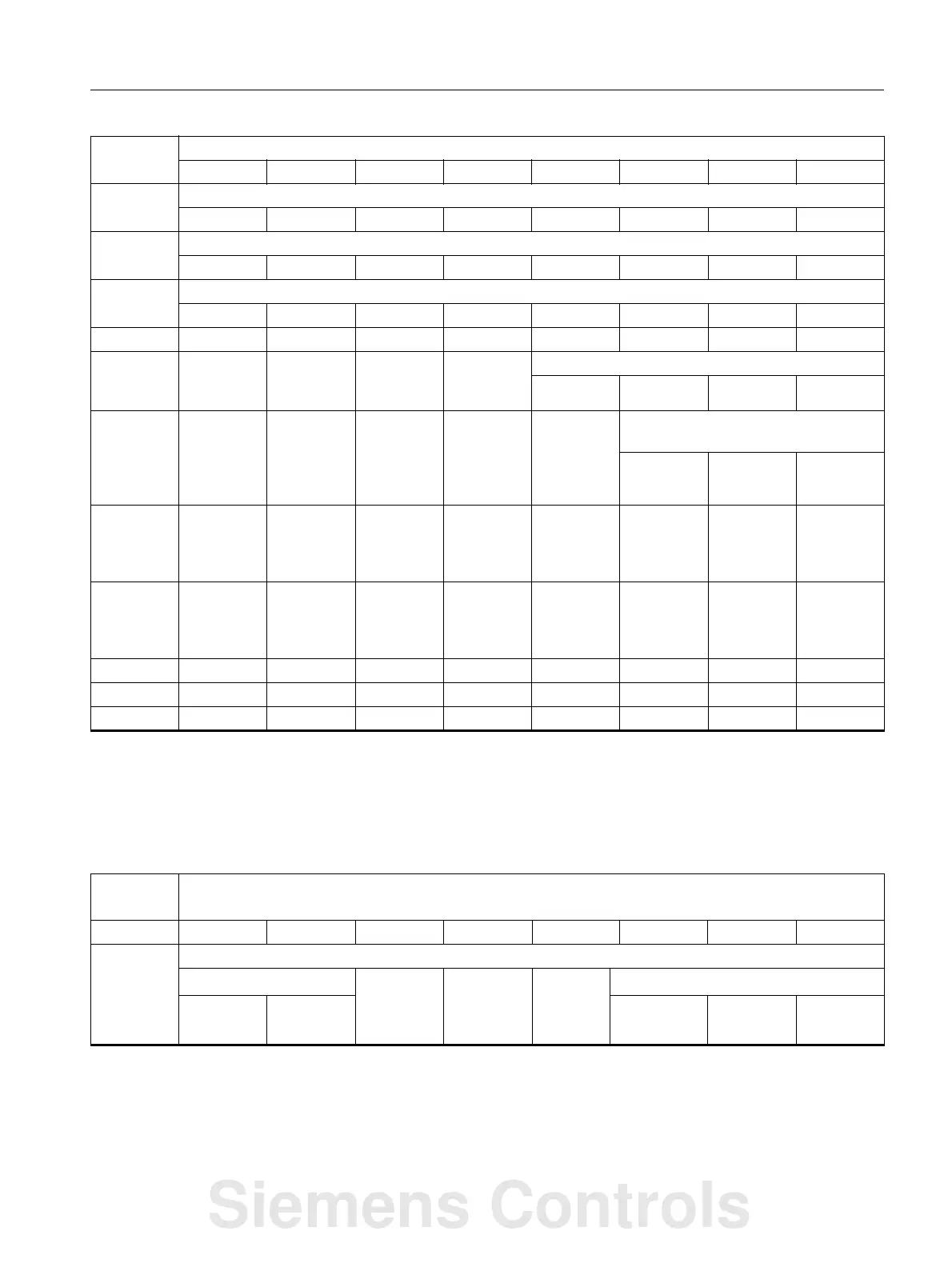

DB3200 Signals to NCK channel [r/w]

PLC -> NCK interface

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

1000 Axis 1 in Work

Traversing keys Rapid

traverse

override

Traversing

key

distance

disable

Feedrate

stop

Activate handwheel (bit/binary coded)

1)

Plus Minus 2 1

1)

The handwheel number is represented according to the $MD_HANDWH_VDI_REPRESENTATION machine data in a bit-

coded (=0) or binary-coded (=1) manner.

2)

Machine function: the machine function is only entered if the "INC inputs in the operating-mode signal range active" signal

(DB2600DBX1.0) is not set.

Siemens Controls

Loading...

Loading...