PLC User Interface

5.8 Channel signals

Parameter Manual

442

Operating Instructions, 08/2013, 6FC5397-8EP40-0BA0

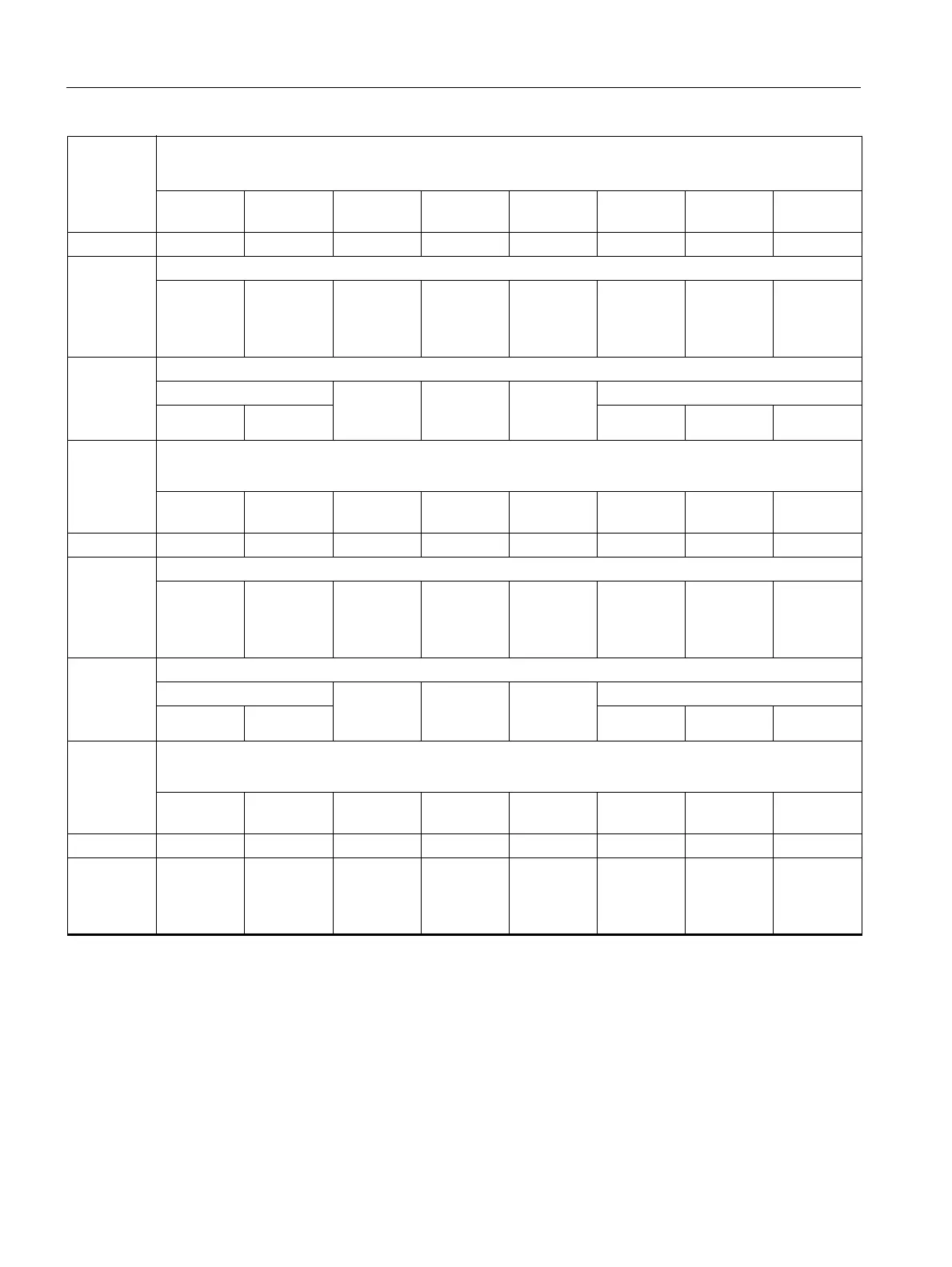

1001 Axis 1 in Work

Machine function

2)

Continuous

traversing

Var. INC 10000 INC 1000 INC 100 INC 10 INC 1 INC

1002

1003

Handwheel

direction of

rotation

inverted

1004 Axis 2 in Work

Traversing keys Rapid

travers

override

Traversing

key disable

Feedrate

stop

Activate handwheel (bit/binary coded)

Plus Minus 2 1

1005 Axis 2 in Work

Machine function

Continuous

traversing

Var. INC 10000 INC 1000 INC 100 INC 10 INC 1 INC

1006

1007

Invert

contour

handwheel

direction

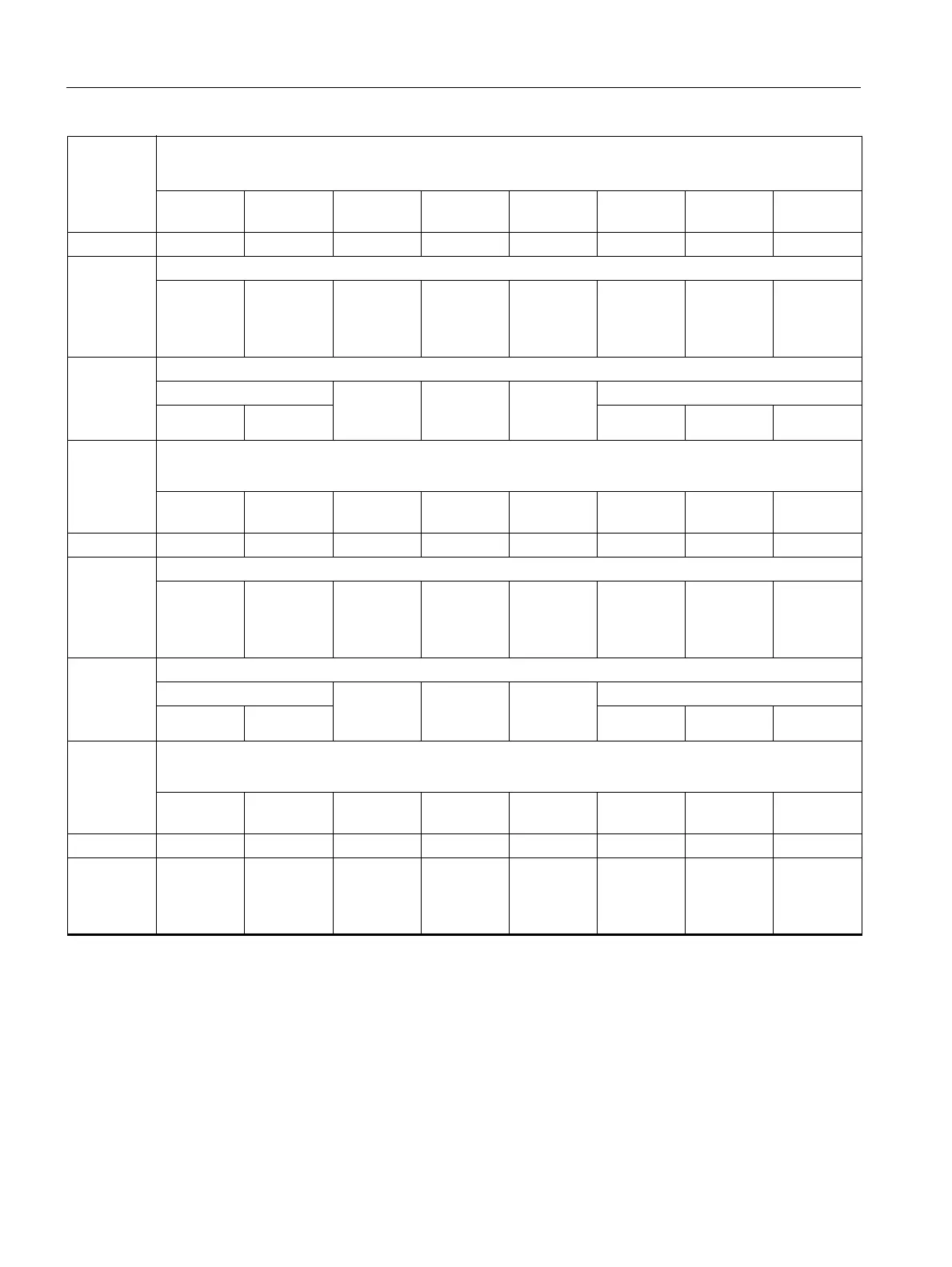

1008 Axis 3 in Work

Traversing keys Rapid

traverse

override

Traversing

key disable

Feedrate

stop

Activate handwheel (bit/binary coded)

Plus Minus 2 1

1009 Axis 3 in Work

Machine function

Continuous

traversing

Var. INC 10000 INC 1000 INC 100 INC 10 INC 1 INC

1010

1011 Invert

contour

handwheel

direction

1)

The handwheel number is represented according to the $MD_HANDWH_VDI_REPRESENTATION machine data in a bit-

coded (=0) or binary-coded (=1) manner.

2)

Machine function: the machine function is only entered if the "INC inputs in the operating-mode signal range active" signal

(DB2600DBX1.0) is not set.

Loading...

Loading...