Troubleshooting Procedures

3.6 Change in Valve Stroke

PS2 Troubleshooting Guide

20 Service Manual, 03/2017, A5E36661550-AA

Change in Valve Stroke

Process Build Up

Process materials can build-up on valves and valve seats. This can prevent a valve from

fully closing, and cause the process to leak through the valve. Additionally process build-up

can prevent the valve from fully opening.

● Put PS2 in Manual mode- from Auto, press button once.

● While pressing and holding

button, press and hold button. This will move the valve

to an end-stop position. To move valve in opposite direction, reverse push button

sequence; while pressing and holding

button, press and hold .

● Use this two-push button method to drive valve fully open and fully closed.

● Utilize pressure gauges to determine if PS2 is outputting full supply pressure and

exhausting all output pressure.

–

For single-acting (one airline to actuator)

One end-stop position should show full supply pressure. The other end-stop position

will show zero pressure.

–

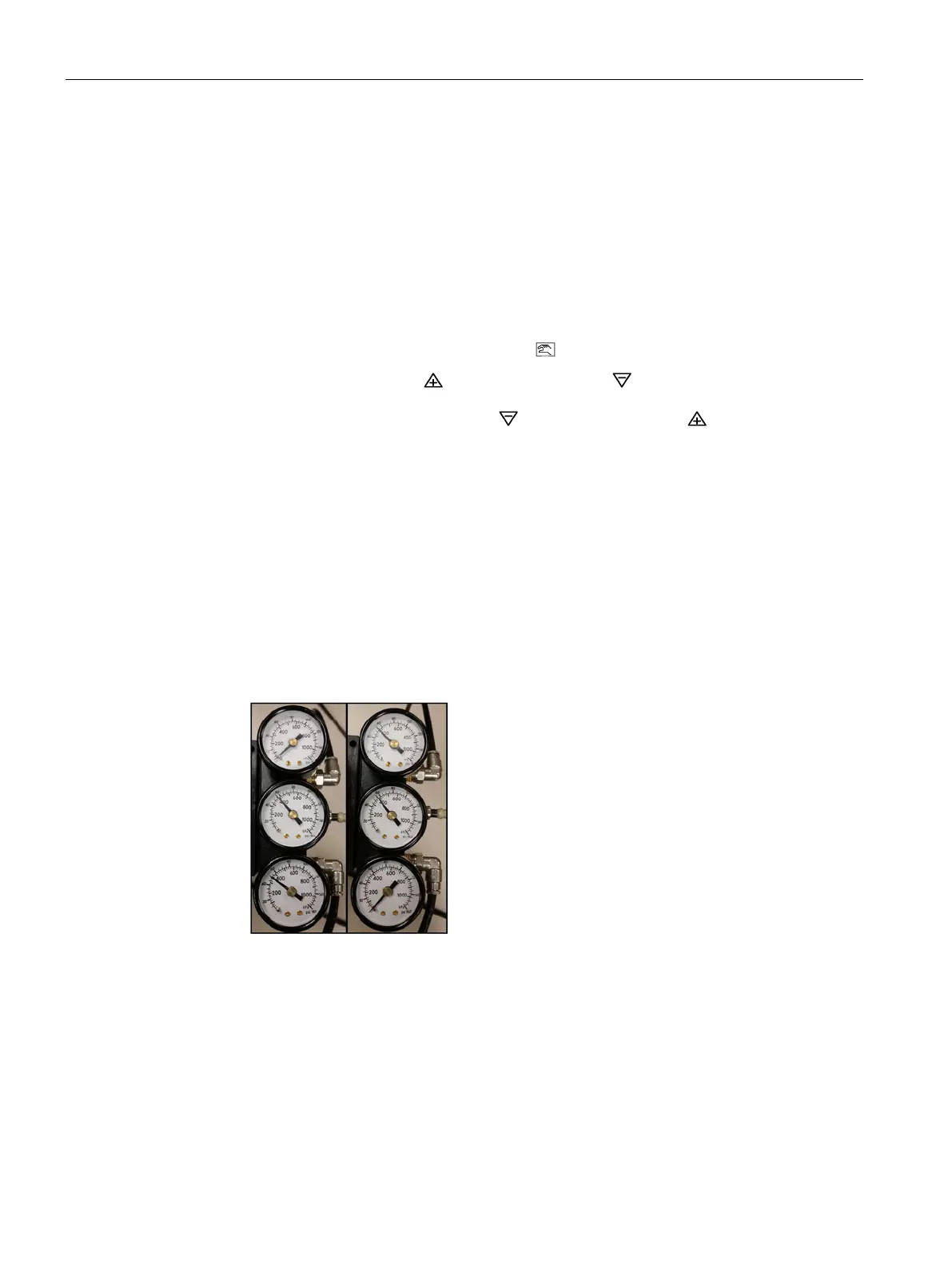

For double-acting (two airlines to actuator)

One end-stop position should show full supply pressure, while the other gauge should

show zero pressure. Output pressures will be reversed when driving valve to other

end-stop position, see following example of double-acting pressure gauges at each

end-stop position.

● If PS2 can output full supply and exhaust in both directions, then something else is

preventing actuator from fully closing or opening.

● Verify supply pressure is properly set, see Insufficient Supply Air.

● If valve is still not able to fully close or open, then check actuator/valve for:

– Mechanical binding

– Valve seat wear

Loading...

Loading...