7ML19985AN02 SITRANS LU10 – INSTRUCTION MANUAL Page 3

mmmmm

Introduction

The SITRANS LU10 is capable of monitoring wheat in 60 m (200 ft) high silos, acetone in

45 gallon barrels, or almost anything in between, in any combination. (Ensure the

transducer selected for each vessel suits the material and measurement range required).

This material and measurement range versatility is accomplished by utilizing Siemens

Milltronics patented Sonic Intelligence®. Sonic Intelligence provides high measurement

reliability, regardless of changing conditions within the vessel monitored.

By utilizing ultrasonic echo ranging principles with Sonic Intelligence and velocity

compensation, the SITRANS LU10 provides outstanding measurement accuracy, usually

within 0.25% of range.

The distance calculation may be converted to space, material level, material volume, or

remaining vessel capacity Readings. The Reading chosen (and operating data) for each

vessel is displayed on the Liquid Crystal Display (LCD).

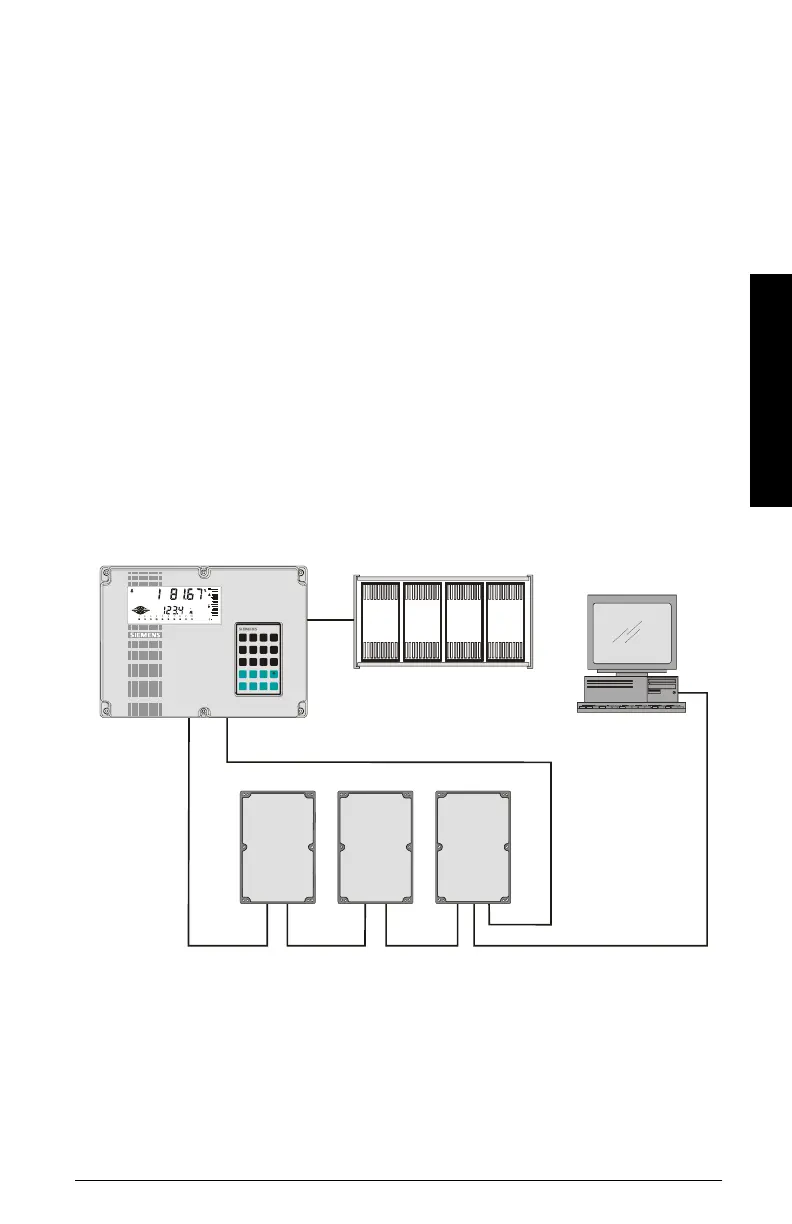

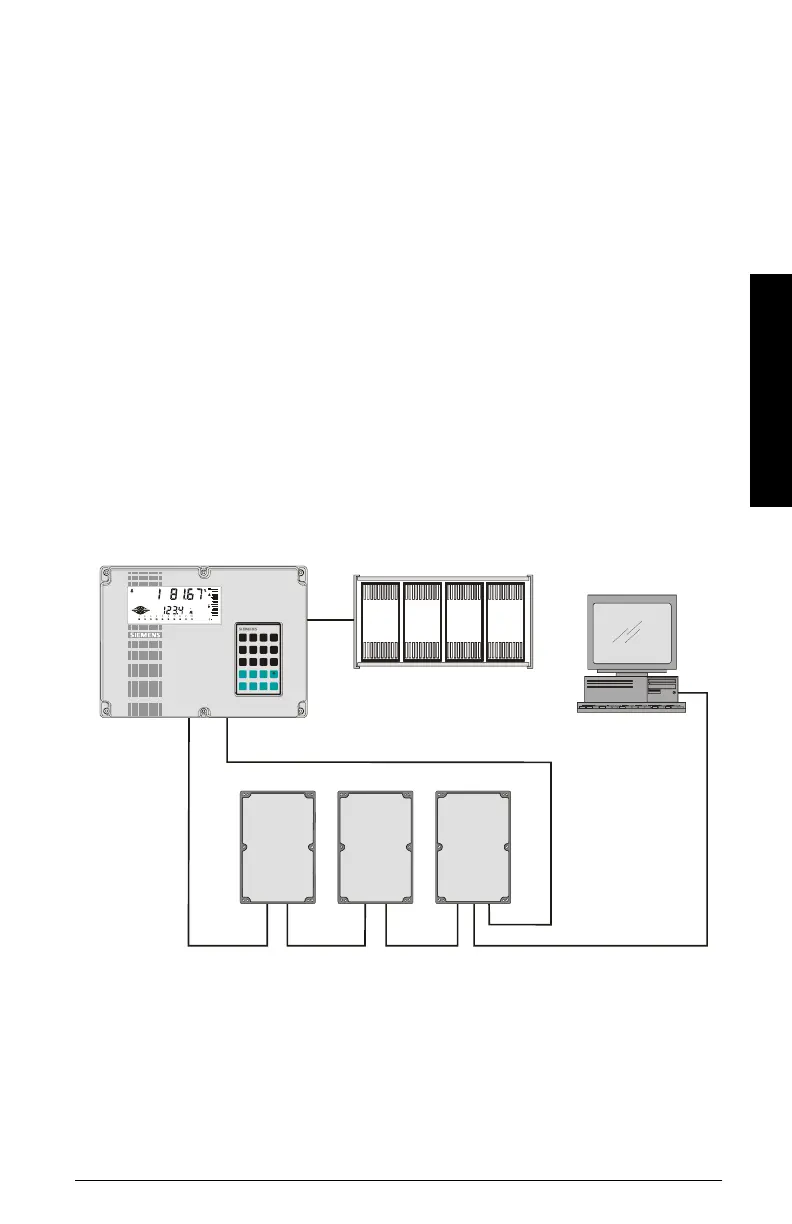

Up to three Siemens Milltronics Peripherals may be connected to the SITRANS LU10. The

LU AO, LU SAM and/or BIC-II, respectively provide analog output , relays, and RS-232 or

RS-422 communication interface, as programmed by the SITRANS LU10.

With the addition of a Siemens Milltronics SmartLinx protocol specific ‘plug in’

communications module, the SITRANS LU10 is compatible with popular industrial control

system standards.

Operator programming, via a Siemens Milltronics infrared programmer, is stored in non-

volatile memory, unaffected by power interruption. The infrared interface permits one

programmer to be used for any number of SITRANS LU10 level monitors. Upon

programming completion, the removable programmer may be locked away, thereby

securing all programming.

IC - IISAM-20AO-10

1234 5 678 910

SITRANS LU 10

SITRANS LU10

industrial control system

bus

proprietary Siemens Milltronics communications loop

Loading...

Loading...