72

SIVACON S8 Planning Principles – Further planning notes

supply units are increasingly used, for example in ICT

equipment in office rooms, the power factor may even

turn capacitive. In this context, it must be observed that

these power supply units frequently cause system pertur-

bations in the form of harmonics, which can be reduced

by passive or active filters.

• The decision in favour of central or distributed implemen-

tation of compensation is governed by the network

configuration (load center of reactive current sources). In

case of distributed arrangement of the compensation

systems, appropriate outgoing feeders (in-line switch-dis-

connectors, circuit-breakers etc.) shall be provided in the

switchboard.

• Generator-supplied power systems must not be com-

pensated if problems may arise in generator control as a

result of compensation control (disconnecting the com-

pensation system during switch-over to generator mode

or static, generator-tuned compensation is possible)

• Choking of a compensation system depends on the

power system requirements as well those of the client

and the DSO.

In the planning stage, installation conditions such as

clearances, width of maintenance gangways, weights,

underground, as well as environmental conditions, for

example climatic conditions, and power loss must already

be considered. In particular the following aspects should be

kept in mind when planning a switchboard:

• Maximally permitted equipment of a cubicle (for

example, number of in-line switch-disconnectors con-

sidering size and load; manufacturer specifications must

be observed!).

• Minimum cubicle width, considering component density,

conductor cross sections and number of cables (a wider

terminal compartment may have to be selected or an

additional cubicle may have to be configured)

• Device reduction factors must be observed according to

manufacturer specifications! Mounting location, ambient

temperature and nominal current play an important part

(particular attention in case of currents greater than

2,000 A!).

• The dimensioning of compensation systems is very much

governed by the location of use (office, production) and

the power supply conditions (harmonic content, DSO

specifications, audio frequency etc.). Up to about 30 % of

the transformer output can be expected as a rough

estimate (in industrial environments) in the absence of

concrete criteria for planning. If switched-mode power

8 Further planning notes

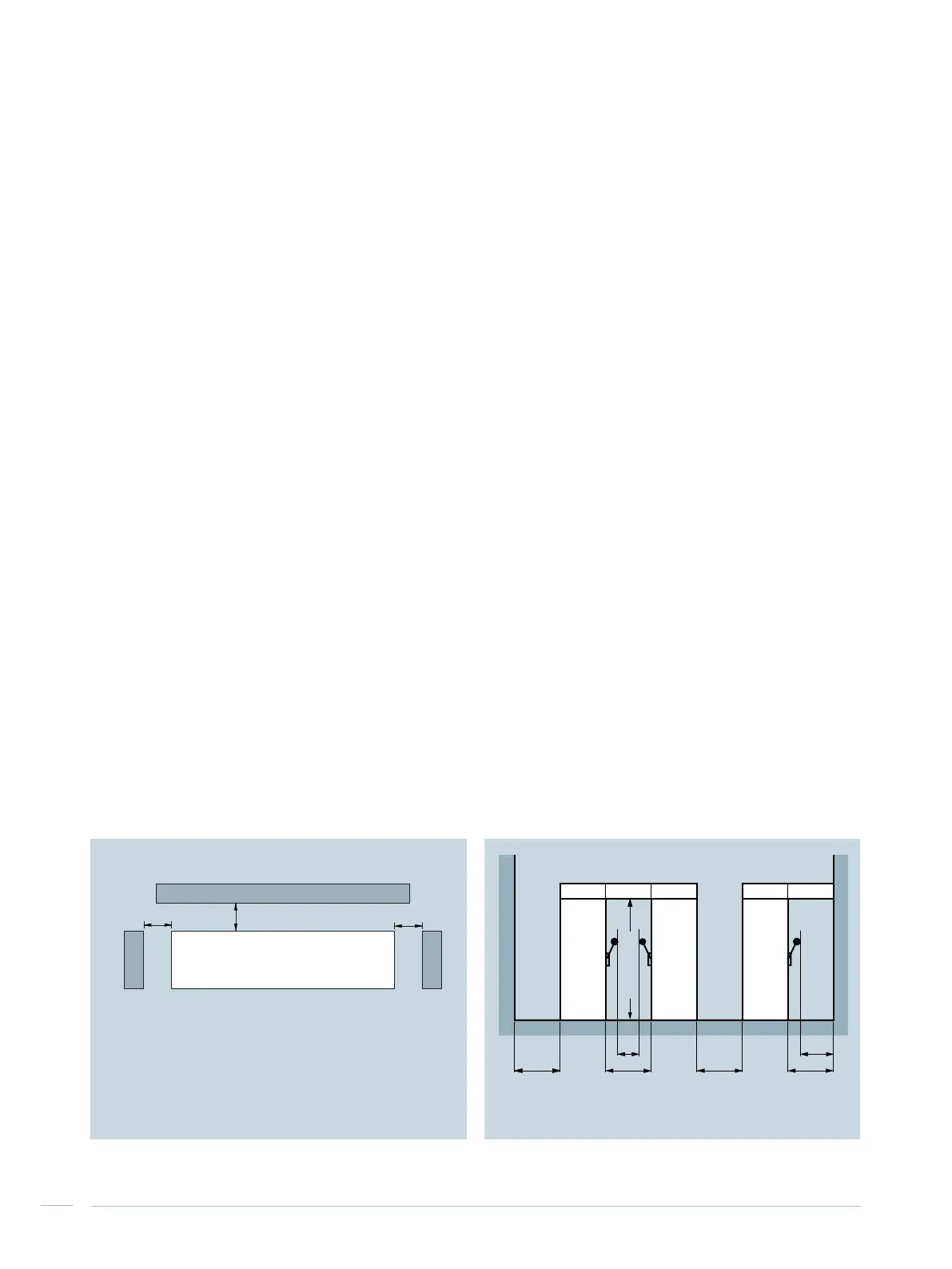

by the manufacturer must be observed (Fig. 8/1). The

minimum dimensions for operating and maintenance

8.1 Installation

Installation – clearances and gangway widths

When low-voltage switchboards are installed, the minimum

clearances between switchboards and obstacle as specified

Fig. 8/1: Clearances to obstacles

100 mm (150 mm

1)

)

2)

100 mm

3)

100 mm

1)

Back-to-back installation: 200 mm (300 mm

2)

)

2)

Only for IP43 (projecting of the top plate)

3)

While adding of the right cubicle, the protrusion of the main busbar connecting brackets must

be considered!

Top busbar position: protrusion 90 mm recommended clearances > 150 mm

Rear busbar position: protrusion 54 mm recommended clearances > 100 mm

Attention: All dimensions refer to the frame dimensions (nominal cubicle size) !

Switchboard

Leave a space of at least 400 mm above the cubicles !

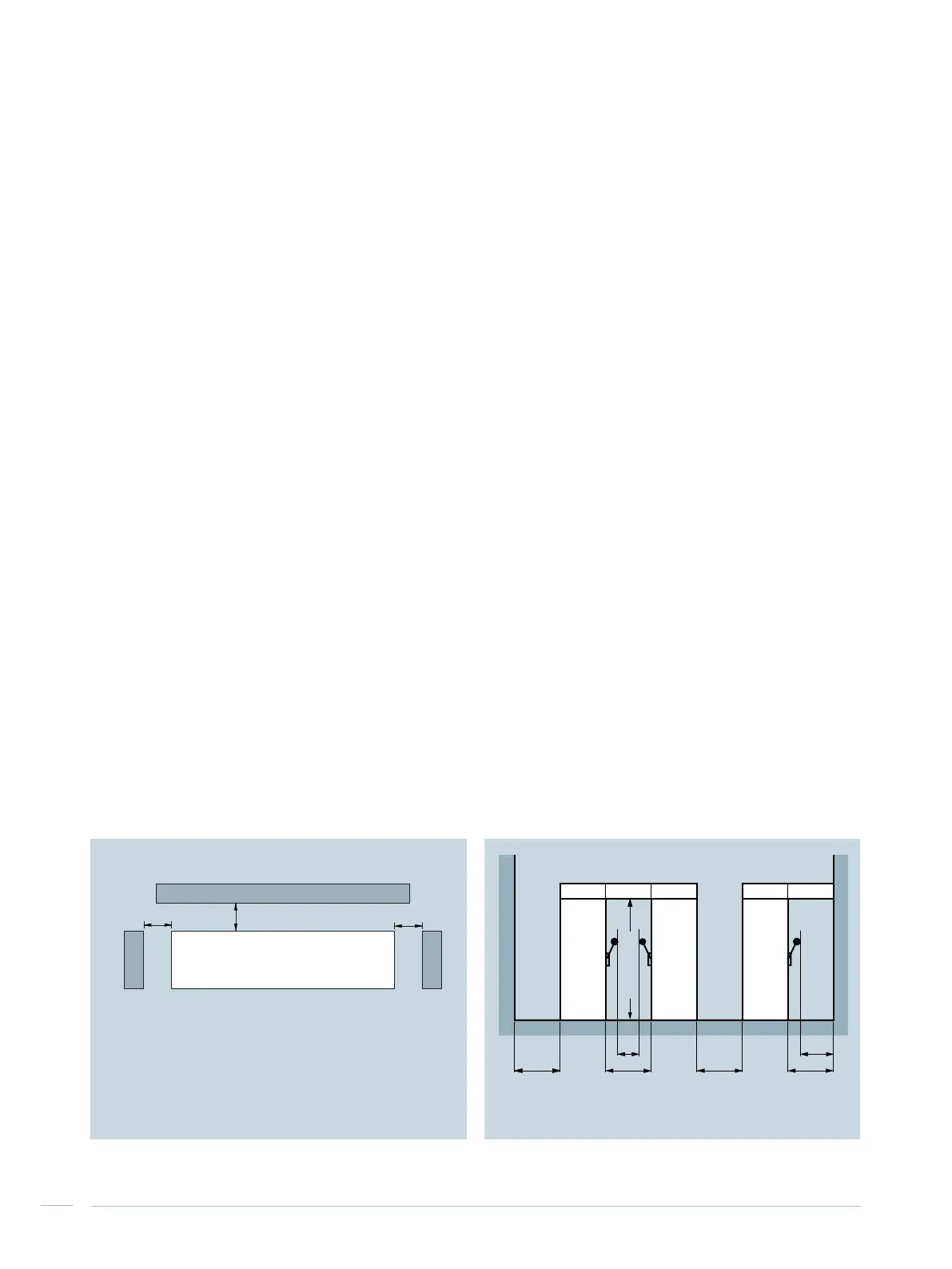

Fig. 8/2: Maintenance gangway widths and passage heights

1)

Minimum height of passage under covers or enclosures

2,000 mm

1)

600 mm600 mm

700 mm700 mm700 mm700 mm

Loading...

Loading...