Notes and requirements for installation and operation VE

- 26 - © SIKA • Ea4500_VE • 02/2019

3 Notes and requirements for installation and operation

Observe the following instructions to achieve the highest possible measurement accuracy

and the specified output signal:

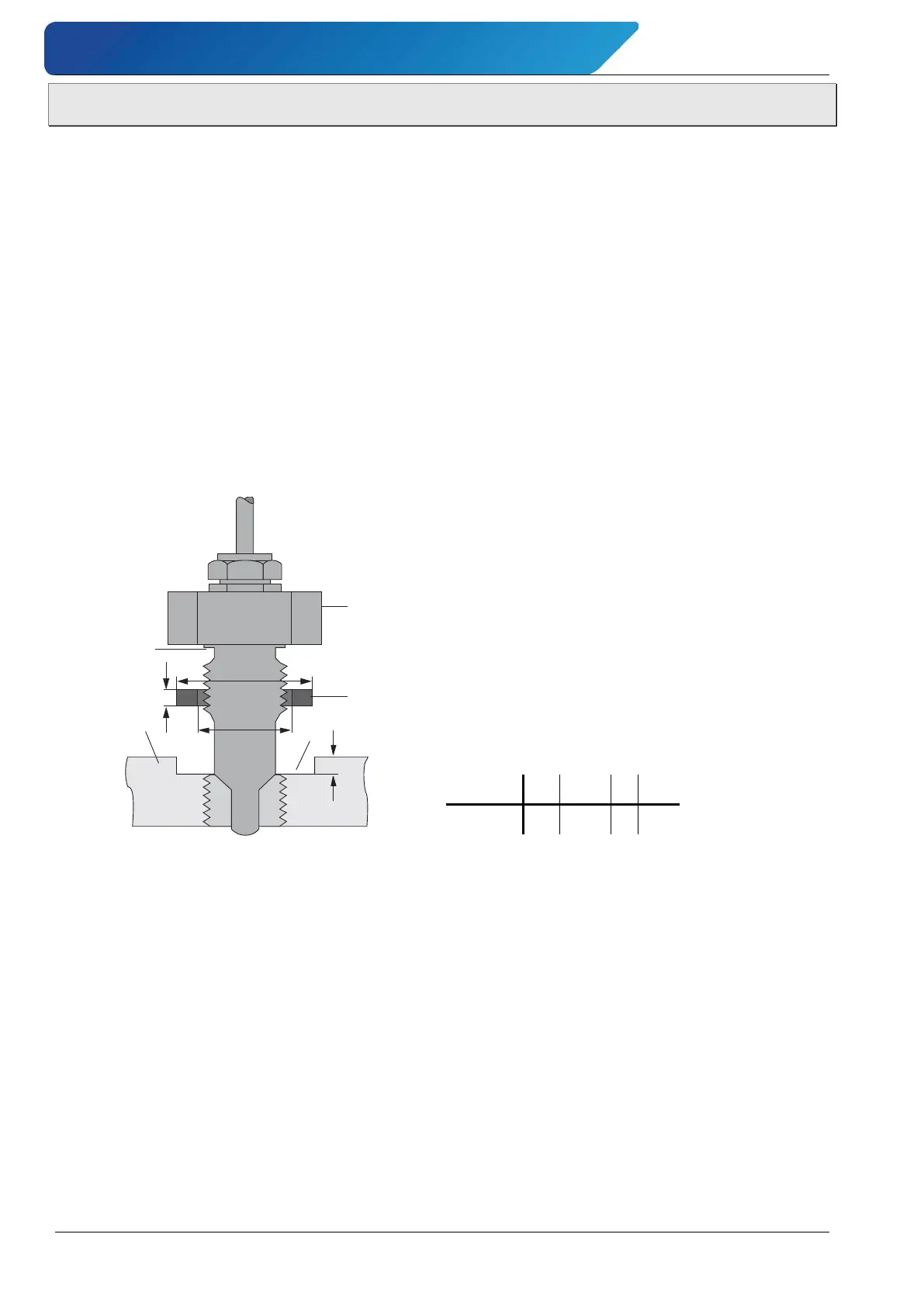

• A screw-in sleeve with female thread G½ is required for installation in the pipeline.

• If the flow monitor cannot be easily screwed in, do not rework or re-cut its thread under

any circumstances. This will destroy the flow sensor. If necessary, you can rework the in-

ternal thread of the screw-in sleeve.

• The sealing is done with a flat gasket which is centred on the sensor by the guide shoul-

der. Make sure that the sleeve has a flat sealing surface.

• You can also seal the thread using PTFE sealing tape or liquid sealant.

• For pressures above 30 bar, you must provide a chamber to prevent the gasket from de-

flecting under high loads. PTFE gaskets must generally be chambered. For high pressure

applications you must use metal gaskets.

• The standard material for gaskets is AFM 34.

1: Sensor

2: Flat gasket

3: Chamber

4: Shoulder

5: Counterpart

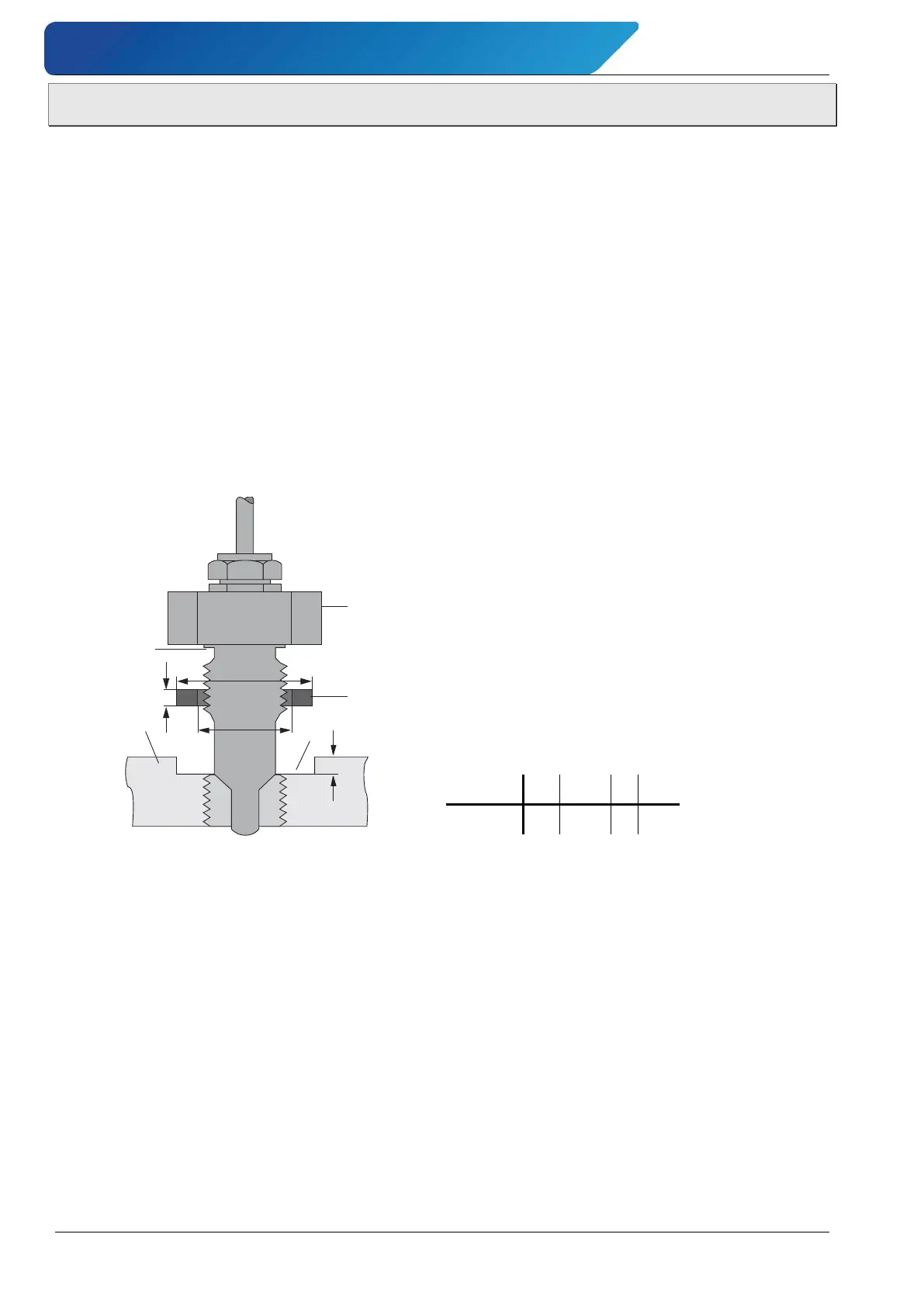

Dimensions of gasket

21 27,5 2 1,5

Fig. 1.: Installation of flow monitor

(applies to VES and VEG)

Loading...

Loading...