46

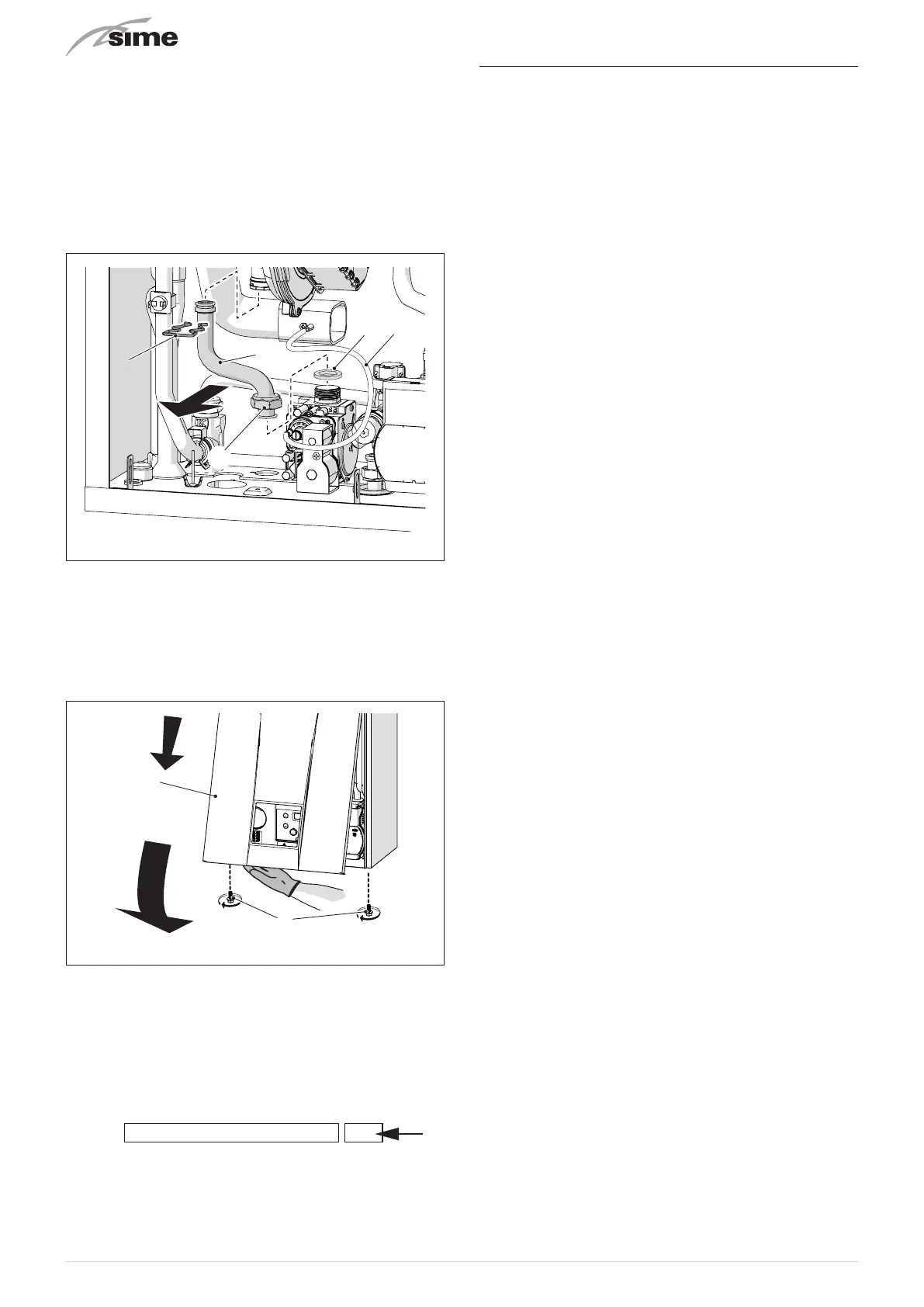

– loosen the ring nut (3) and the spring clip (4) of the gas pipe

(5)

– detach the gas pipe (5) from the gas valve and from the mix-

er, making sure that the silicone pipe (6) does not hinder the

operations; if it does, remove it

– replace the old nozzle (7) with the new one for G31, as

shown in the figure

– put the gas pipe (5) back on and tighten the ring nut (3) on

the gas valve

– put the spring clip (4) back onto the mixer

– put the previously removed silicone pipe (6) back on

4

5

7 6

3

Fig. 56

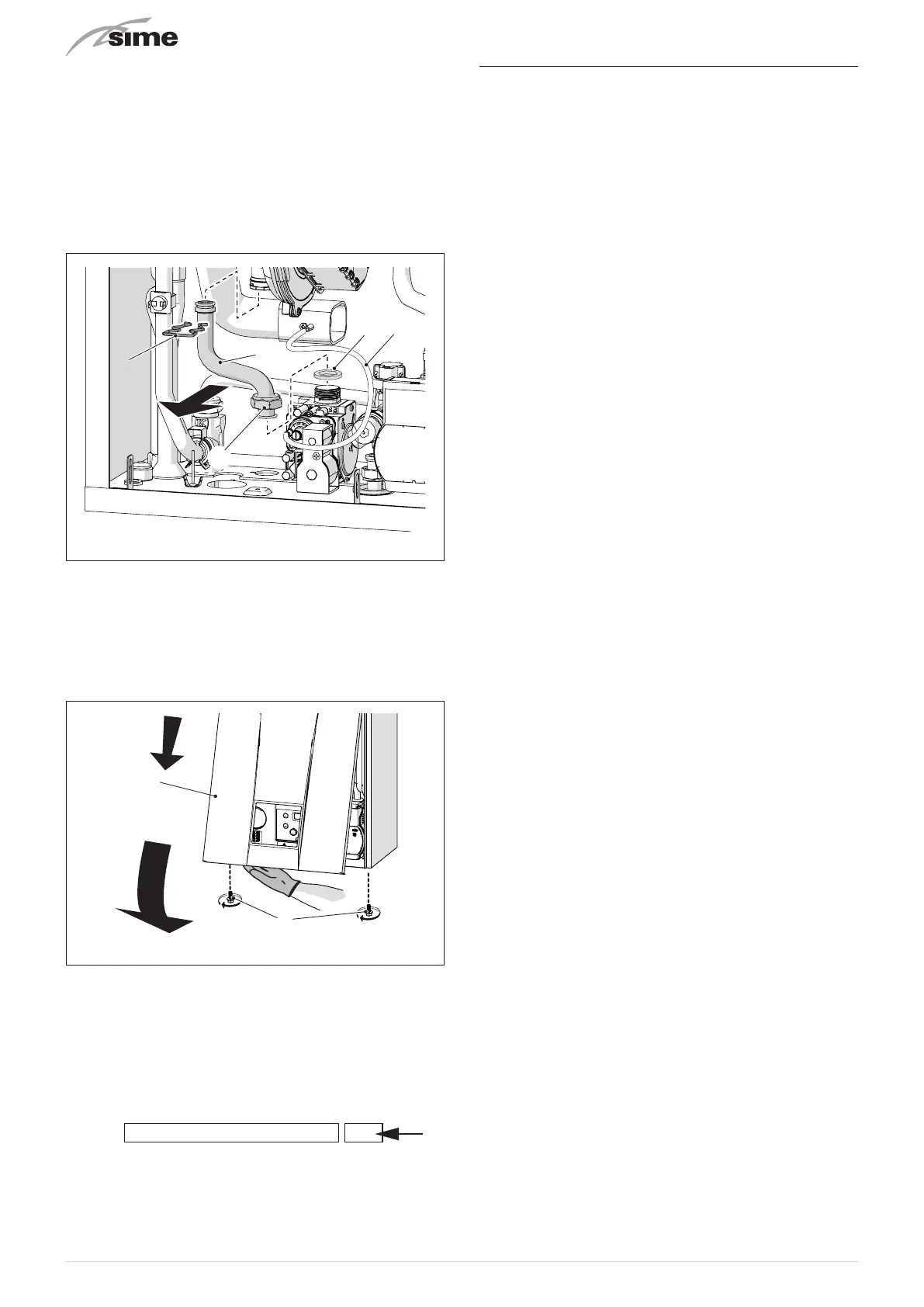

– access the installer parameters and modify parameter tS

0.1 on the basis of the power and gas used, as indicated

in the table in the “Circuit Board Replacement” paragraph

– perform the “Chimney sweep function” function to correct-

ly set the CO

2 of the boiler with the new gas and then mount

the front panel (2) back on, securing it with the two screws

(1).

2

1

Fig. 57

m

CAUTION

Conversion may ONLY be carried out by Profession-

ally Qualified Personnel.

m

CAUTION

If the gas supply is changed from G20 to G31, mark

the box on the TECHNICAL DATA PLATE.

G31 - 37 mbar

7.8 Heating power output adjustment

To comply with Building regulations, the heating output must

be set according to the requirements of the installed heating

system.

This is done by adjustment of "parameter 15" (tS 1.5).

Calculate the heating requirements of the heating system in

kW. Determine what that value is, as a % of the nominal heat

output of the boiler, see table "Technical features" page 18.

Access the parameters as shown in "Parameter setting and

display" page 40, and adjust the parameter 15 (tS 1.5) to that

% value

Example:

–

Heating system with 8 radiators, average 1.5 kW per radia-

tor total heat

–

Requirement 12 kW (8 x 1.5)

–

Maximum nominal heat output of boiler = 23.6 kW

–

Parameter 15 (tS 1.5) = 12/23.6 = 50.8%. Set tS 1.5 to 51%.

m

CAUTION

As a condition of the warranty and to ensure correct

operation and efficiency, it is important that the boil-

er is serviced every 12 months, within 30 days of the

anniversary of the installation date ensure the re-

quired information is recorded in the Gas Boiler Sys-

tem Service Interval Record (page 52) (Benchmark).

Loading...

Loading...