49

8.4 Checks

8.4.1 Checking the flue

Check that the flue is undamaged and complete.

8.4.2 Checking the expansion vessel pressure

It is recommended that the expansion vessel on the water side

is drained and that the prefilling pressure is not less than

1

bar

. If this is not the case, pressurize it to the correct value

(see section "Expansion vessel").

Once the checks described above have been completed:

– refill the boiler as described in section "SYSTEM Filling"

– check that the siphon has been filled correctly

– Start the boiler, activate the "Chimney sweep function" and

carry out combustion analysis as detailed in Appendix 2

– refit the front panel securing it with the two screws which

were removed previously.

8.5 Circuit Board Replacement

Type No. Description

Setting for

GIULIA

SYSTEM

25

tS 0.1

Index showing boiler power

in kW

0 = 25 (METHANE)

2 = 25 (GPL)

0

tS 0.2

0 = combi

1 = storage tank with

thermostat or heating only

2 = N/A

3 = N/A

4=instant with solar power

input

5 = open vent

6 = KIT HYBRID instant boiler

7 = Edea Hybrid

8 = Edea Hybrid SPAIN

CENTRALIZED

9 = HYBRIDWALL istant boiler

10 = HYBRIDWALL hot water

tank boiler

1

To enter "Parameter setting and display" refer to the indica-

tions provided in the specific section.

If the

gas valve

are replaced, the user must still carry out the

entire phase of "Chimney sweep function" described in the

specific section.

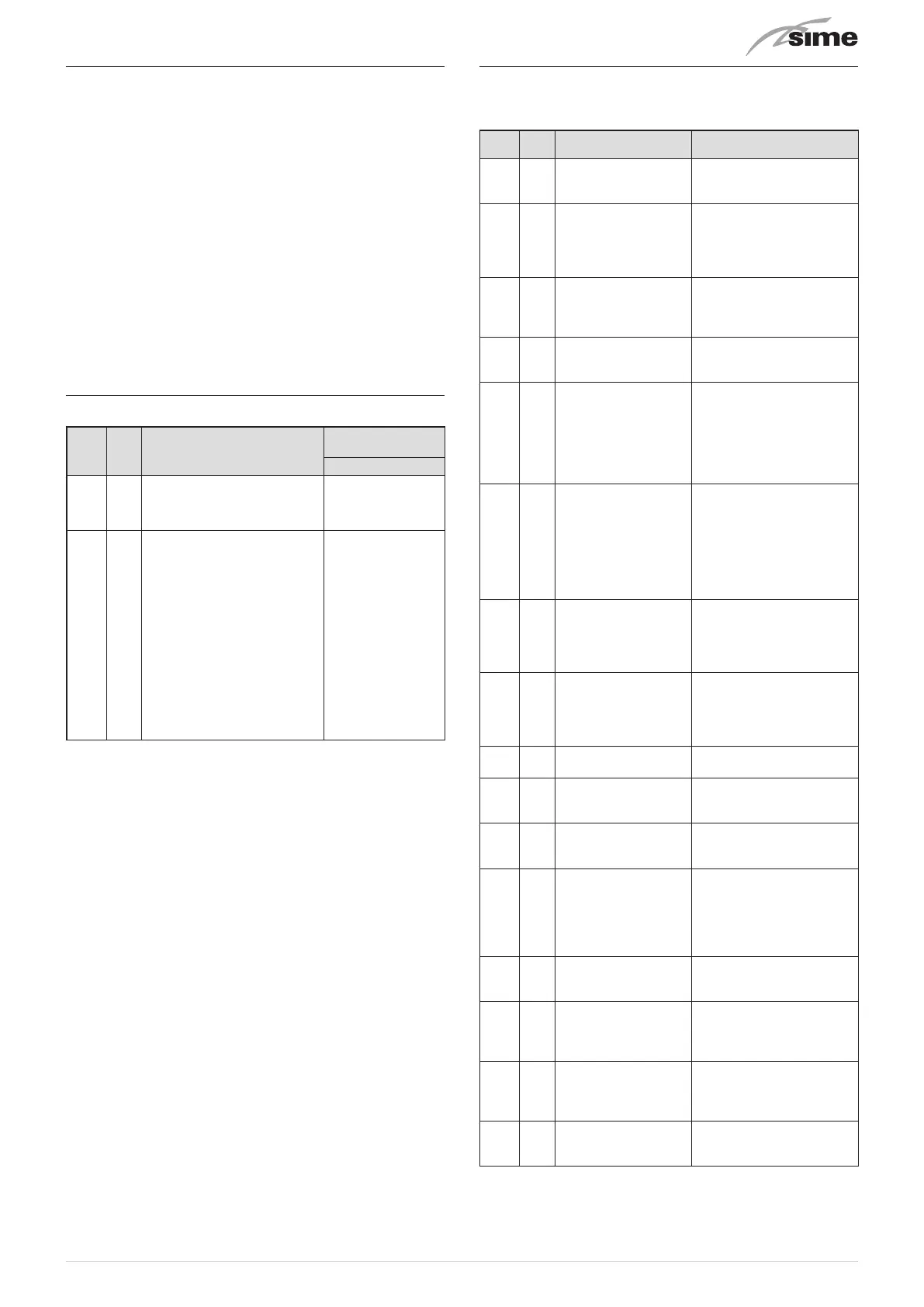

8.6 Malfunction codes and possible solutions

LIST OF MALFUNCTION/FAULT ALARMS

Type No. Fault Solution

AL 02

Low water pressure in

system

- Restore pressure

- Check for any leaks in the

system

AL 03

High water pressure in

system

- Empty the system via

the drain valve on the

hydraulic assembly and

bring the pressure to

approximately 1.2 bar

AL 04

Domestic hot water

sensor fault (return

sensor fault for T

models)

- Check connections

- Check the sensor is

working

AL 05 Delivery sensor fault

- Check connections

- Check the sensor is

working

AL 06 No flame detection

- Check the integrity of the

electrode and check that it

is not grounded

- Check gas availability and

pressure

- Check the operation of the

gas valve

AL 07

Safety thermostat

intervention

- Check the sensor or

thermostat connections

- Deaerate the system

- Check the bleed valve

- Replace the sensor or the

thermostat

- Check that the pump

impeller is not blocked

AL 08

Fault in the flame

detection circuit

- Check the integrity of the

electrode and check that it

is not grounded

- Check the operation of the

gas valve

AL 09

No water circulating in

the system

- Check the rotation of the

pump rotor

- Check the electrical

connections

- Replace the pump

AL 11

Gas valve modulator

disconnected

- Check the electrical

connection

AL 12

Domestic hot water

sensor fault in tank

mode

- Set the parameter tS 0.4

(Combustion configuration)

to 0

AL 13

Exhaust sensor

intervention

- Check the sensor is

working

- Replace the smoke probe

AL 14 Exhaust sensor fault

- Replace the smoke probe

- Check the electrical

connection of the smoke

probe

- Contact the Technical

Assistance Centre

AL 15

Fan check cable

disconnected

- Check the connection

cable between the fan and

the board

AL 28

Maximum number of

consecutive resets

reached (6)

- Wait 1 hour and try

unblocking the board again

- Contact the Technical

Assistance Centre

AL 30

Return sensor fault

(boiler sensor fault for

T models)

- Replace the return probe

- Check parameters

- Contact the Technical

Assistance Centre

AL 37

Fault due to low

network voltage

- Check the voltage

- Contact your network

provider

Loading...

Loading...