NANYTE BEAM Manual

NANYTE BEAM Manual BM-001-A3 / V1.1a Page 20 of 33

Patterning

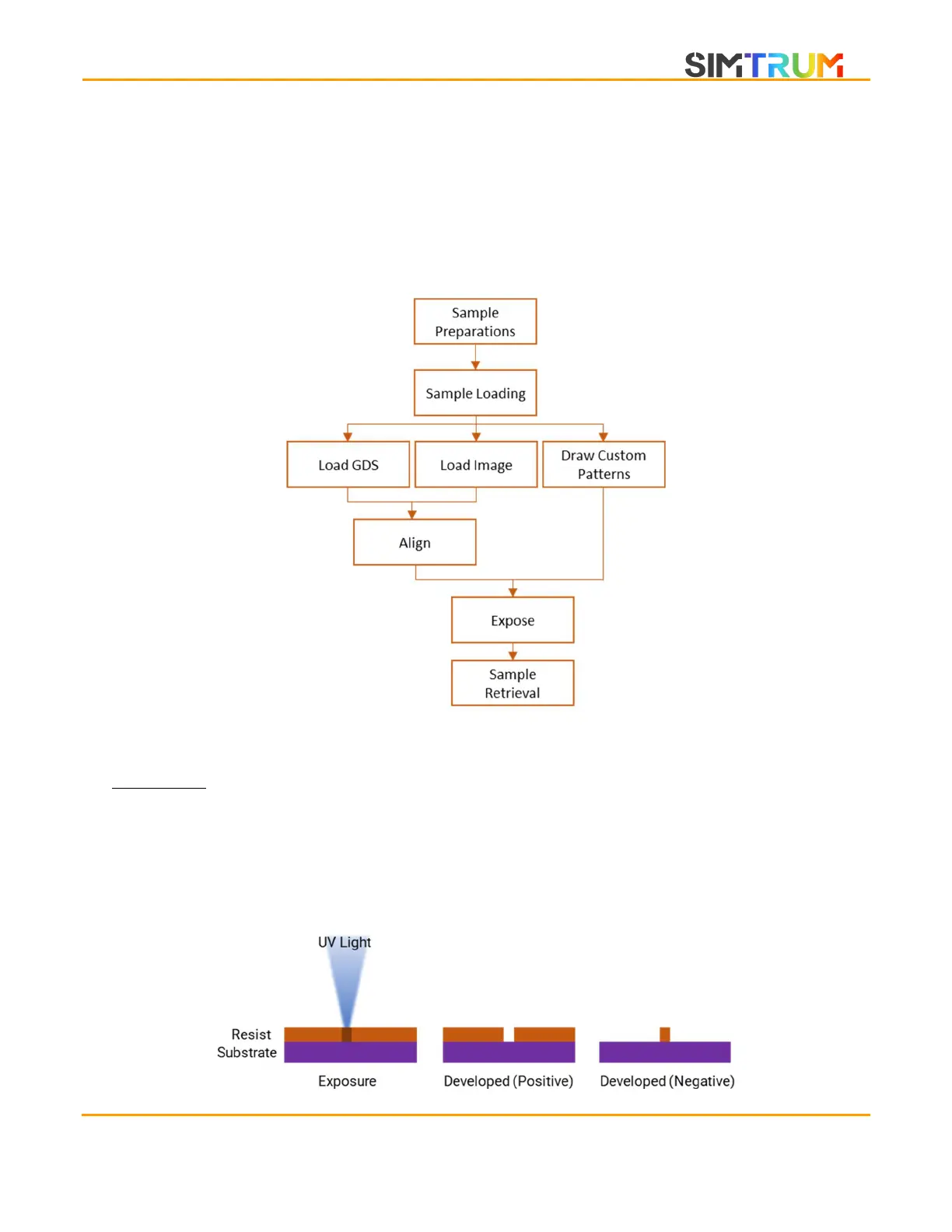

NANYTE BEAM was designed so that the least number of steps are necessary to do a full

exposure. Depending on the complexity of the patterning job, it is possible to load, align and

expose a pattern onto a wafer in under 3 minutes. The flow of the entire patterning process is

as shown below:

Sample preparation and loading

Spin coating

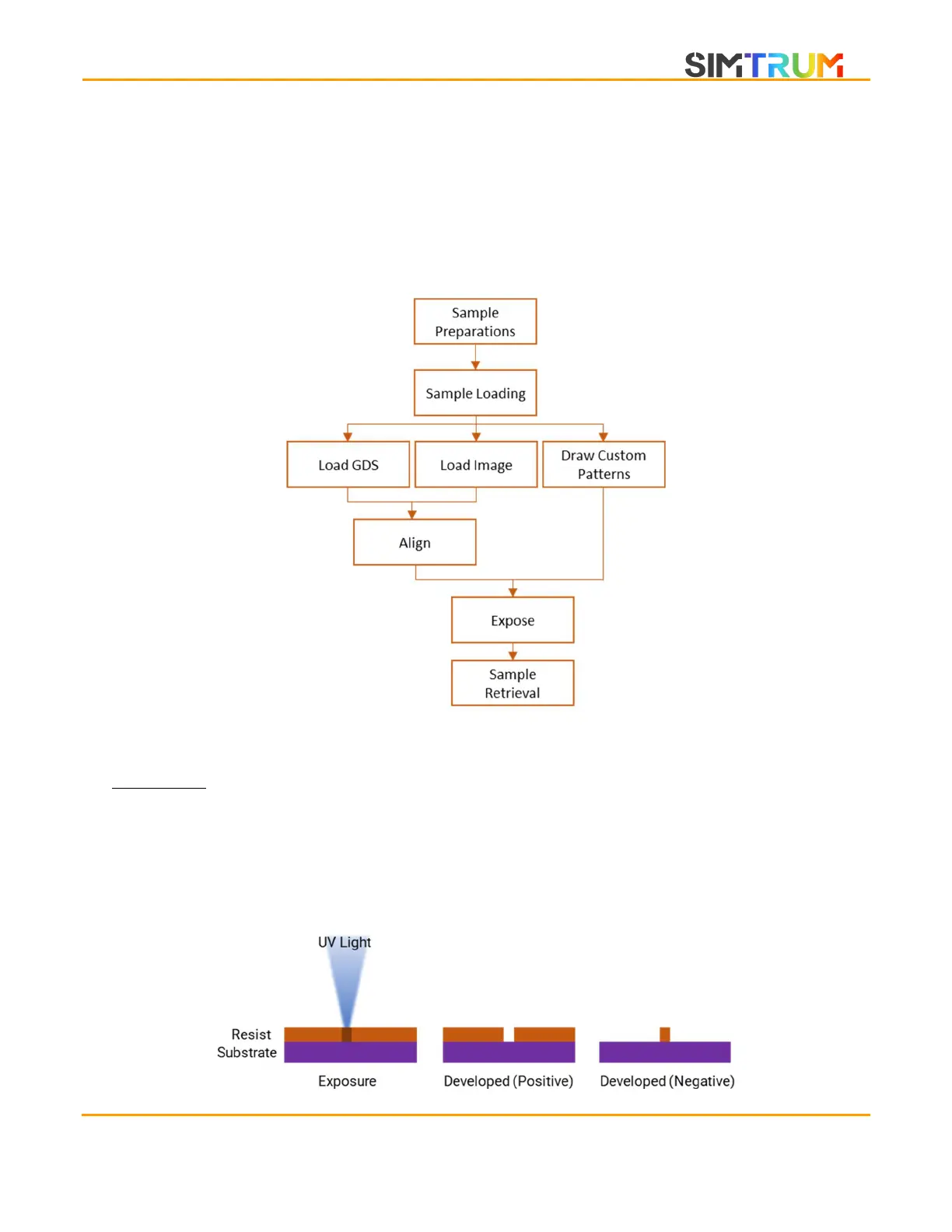

The first step in photolithography is to spin coat a layer of photoresist on to the sample surface.

The BEAM ENGINE uses h-line or 405 nm UV radiation for exposure; thus, an appropriate

photoresist has to be used. Other than spectral sensitivity, it is important to verify that the resist

is of the correct type (positive/negative, see below), and that the thickness is suitable for the

required resolution/aspect ratio.

www.simtrum.com

Loading...

Loading...