MAINTENANCE PROCEDURES

1

2

A05F0EB

TYPICAL

1. Locknut

2. Retaining bolts

6. Start engine and rotate track slowly

to recheck alignment.

7. Reposition snowmobile on ground.

8. Install rear wheel caps if so

equipped.

Suspension

Rear Suspension Condition

Visually inspect all suspension compo-

nents including slider shoes, springs,

wheels, etc.

NOTE: During normal driving, snow

will act as a lubricant and coolant for

the slider shoes. Extensive riding on

ice or sanded snow, will create exces-

sive heat build-up and cause prema-

ture slider shoe wear.

Suspension Stopper Strap

Condition

Inspect stopper strap for wear and

cracks, bolt and nut for tightness. If

loose inspect holes for deformation.

Replace as required. Torque nut to

9N•m±1N•m(80lbf•in ±9lbf•in).

Rear Suspension Lubrication

Lubricate rear suspension at grease

fittings using SUSPENSION GREASE

(P/N 293 550 033). Refer to

MAINTE

-

NANCE SCHEDULE

for maintenance

frequency.

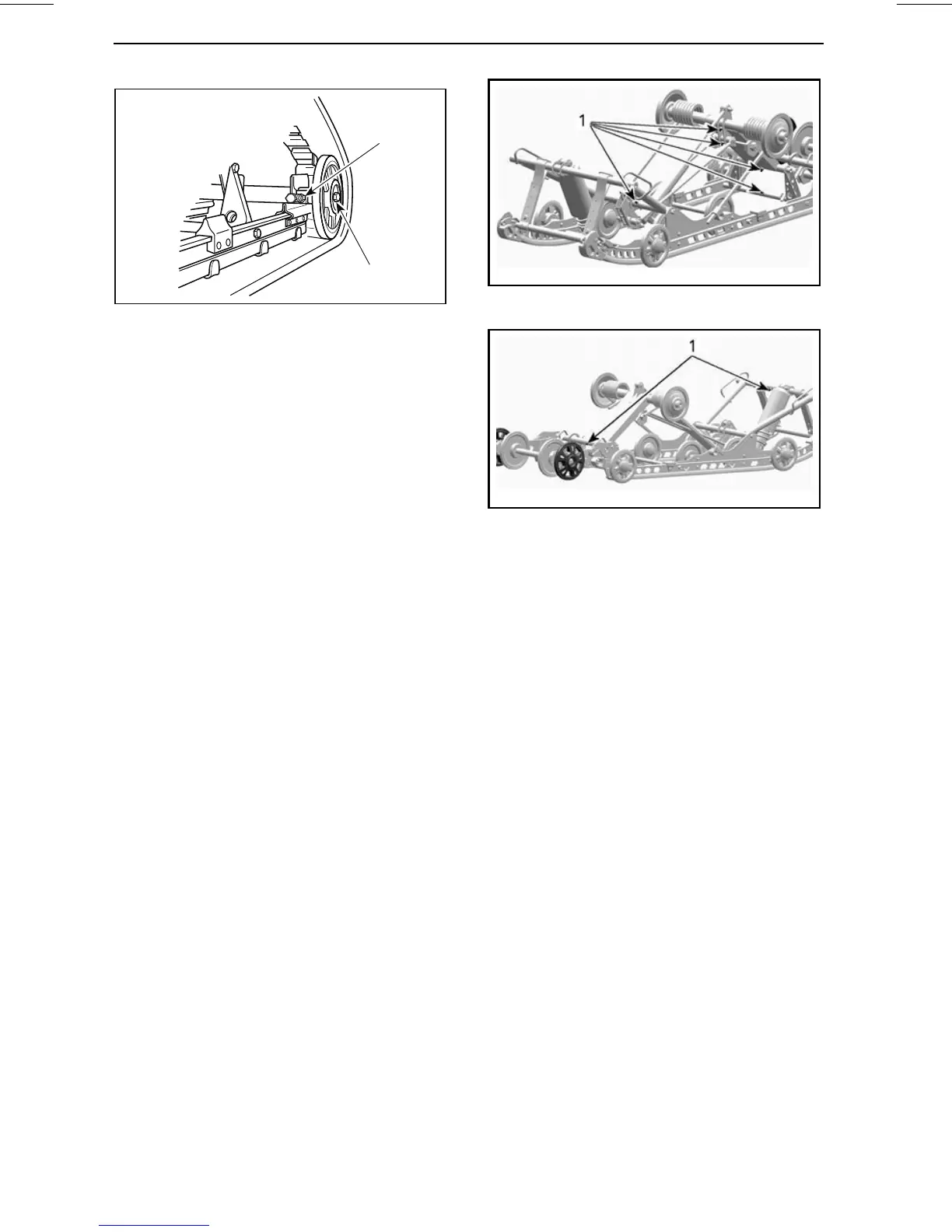

mmo2011-006-003_a

1. Grease fittings

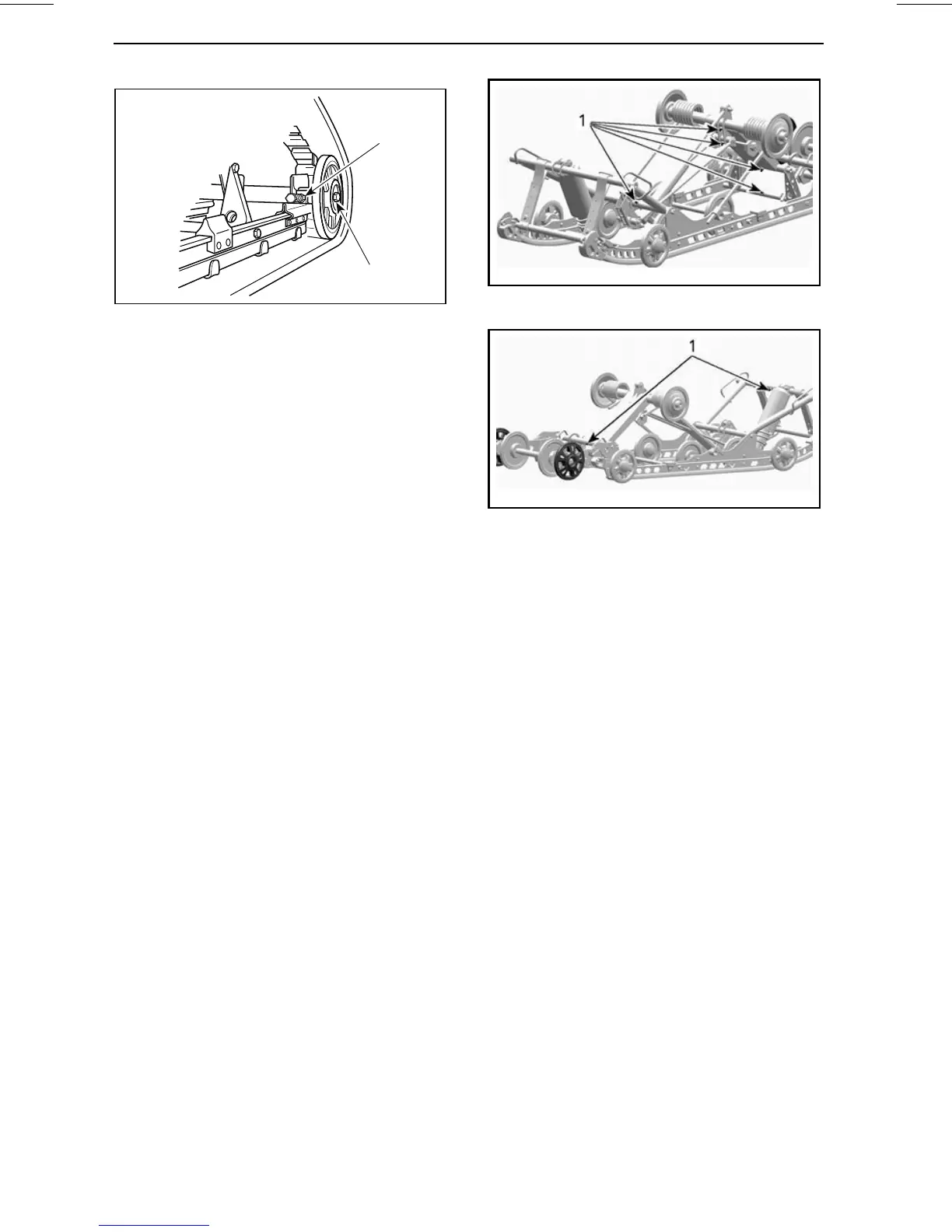

mmo2011-006-004_a

1. Grease fittings

Steering and Front Suspension

Condition

Visually inspect steering and front sus-

pension for tightness of components

(steering arms, tie rods, ski bolts, ski

legs, etc.). If necessary, contact an au-

thorized Ski-Doo dealer.

Front Suspension Lubrication

Lubricate front suspension at grease

fittings using suspension synthetic

grease (P/N 293 550 033).

Generally, 4 to 5 grease gun strokes is

sufficient.

NOTE: If too much grease is injected,

the overflow will come out at steering

levers and ski legs. Wipe off any ex-

cess of grease to avoid contact with

other parts.

78

______________

Loading...

Loading...