213217AAA SJ85 AJ

40

Section 4 – Pre-operation Visual & Daily Maintenance Inspections

4.2 Visual & Daily

Maintenance Inspections

Begin the visual and daily maintenance inspections

by checking each item in sequence for the conditions

listed in this section.

WARNING

To avoid injury, do not operate a MEWP until all

malfunctions have been corrected.

WARNING

To avoid possible injury, ensure MEWP power

is off during your visual and daily maintenance

inspections.

CAUTION

Ensure MEWP is on a rm, level surface.

NOTE

While performing visual and daily inspections

in different areas, be aware to also inspect limit

switches, electrical and hydraulic components.

4.2-1 Labels

Refer to Section 8 in this manual and determine that

all labels are in place and are legible.

4.2-2 Electrical

Maintaining the electrical components is essential to

good performance and service life of the MEWP.

Inspect the following areas for chafed, corroded and

loose wires:

▪

boom to platform cable harness

▪

engine compartment electrical panel

▪

engine wiring harness

▪

rotary manifold wiring

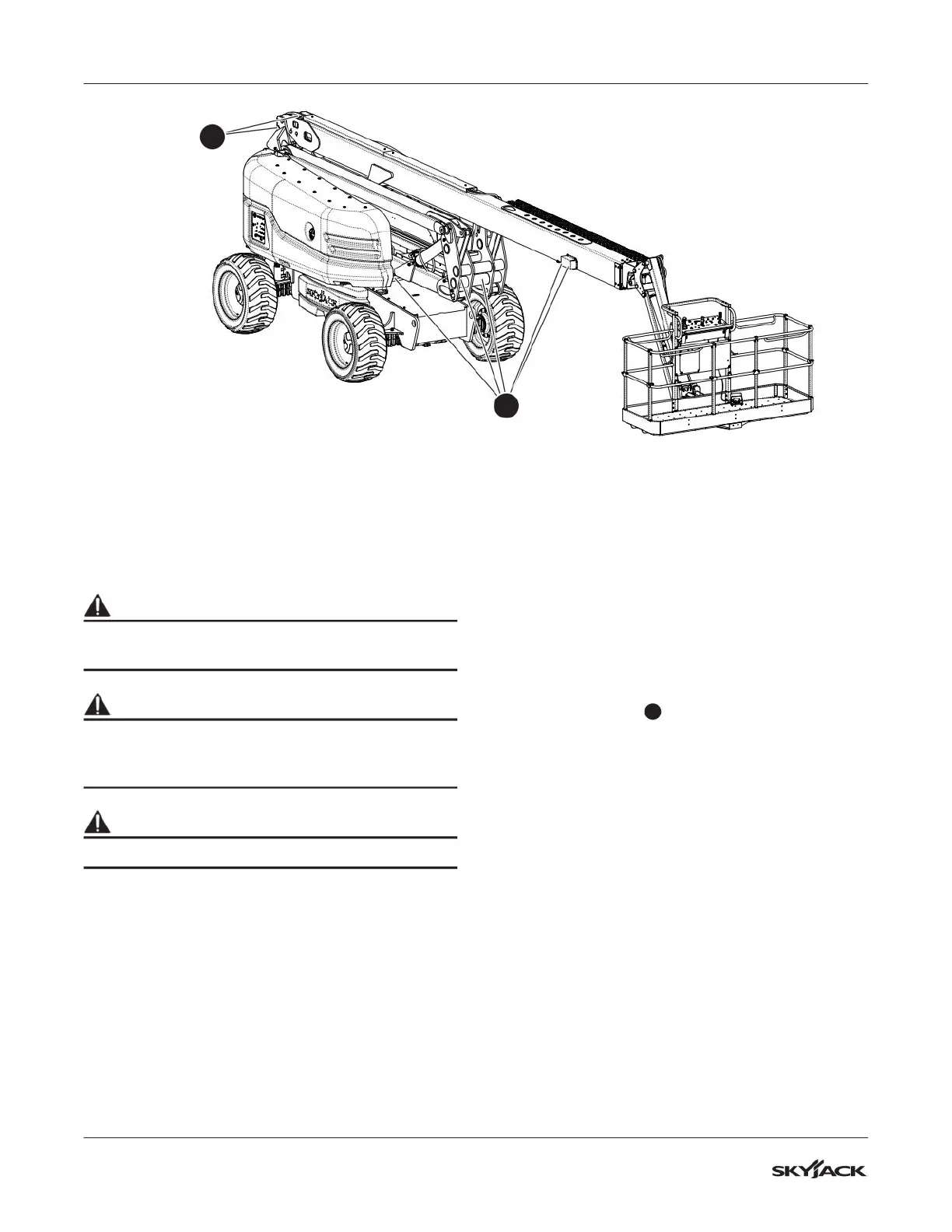

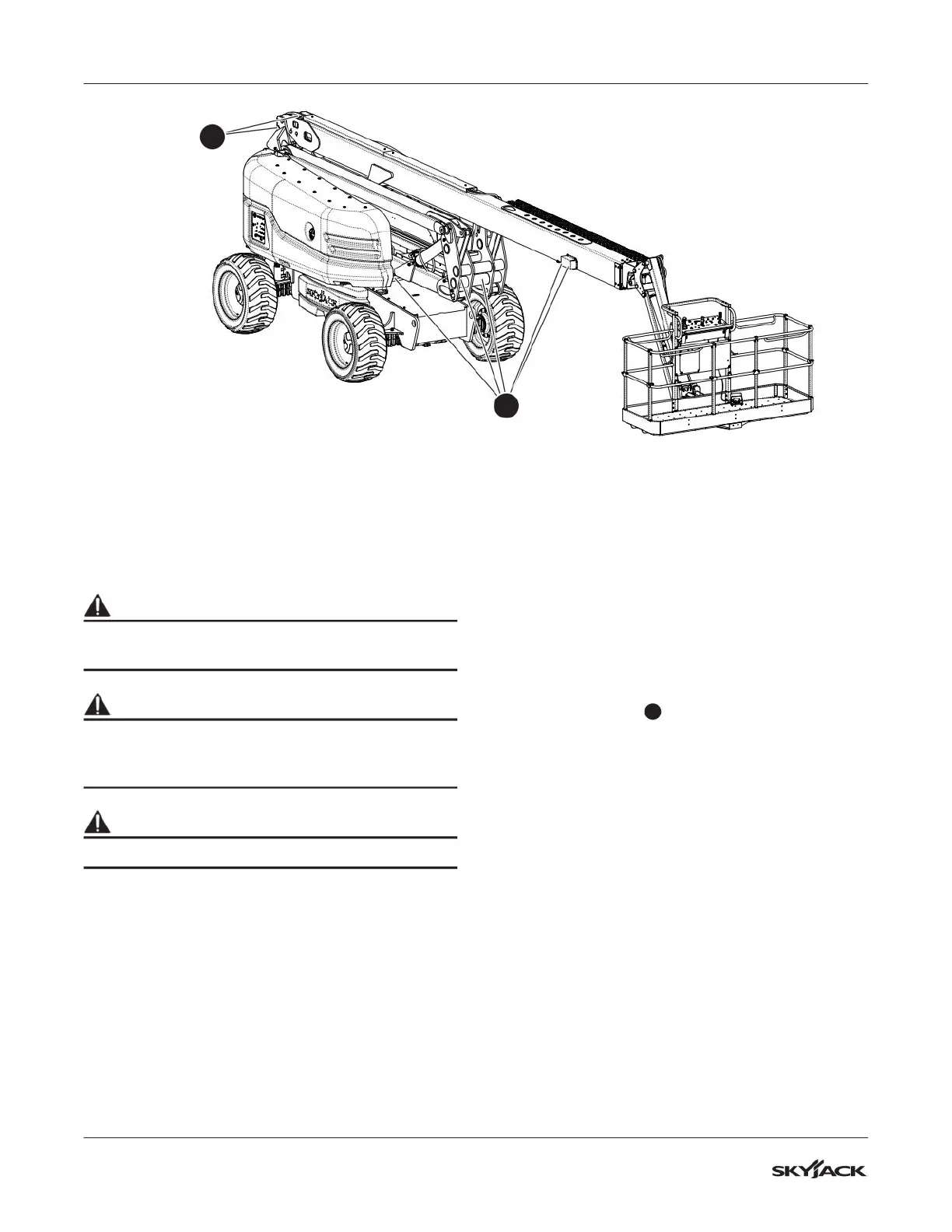

4.2-3 Limit switches

Ensure limit switches

1

are properly secured with

no signs of visible damage and movement is not

obstructed.

4.2-4 Hydraulic

Maintaining the hydraulic components is essential to

good performance and service life of the MEWP.

Perform a visual inspection around the following

areas:

▪

hydraulic tank lter, ttings, hoses, emergency

power unit and turret/base surface

▪

engine compartment ttings, hoses, main pump,

lter and turret/base surface

▪

all hydraulic cylinders

▪

all hydraulic manifolds

▪

the underside of the turret

▪

the underside of the base

▪

ground area under the MEWP

Limit switch locations

1

1

Loading...

Loading...