SJ85 AJ 213217AAA

43

Visual & Daily Maintenance Inspections Section 4 – Pre-operation

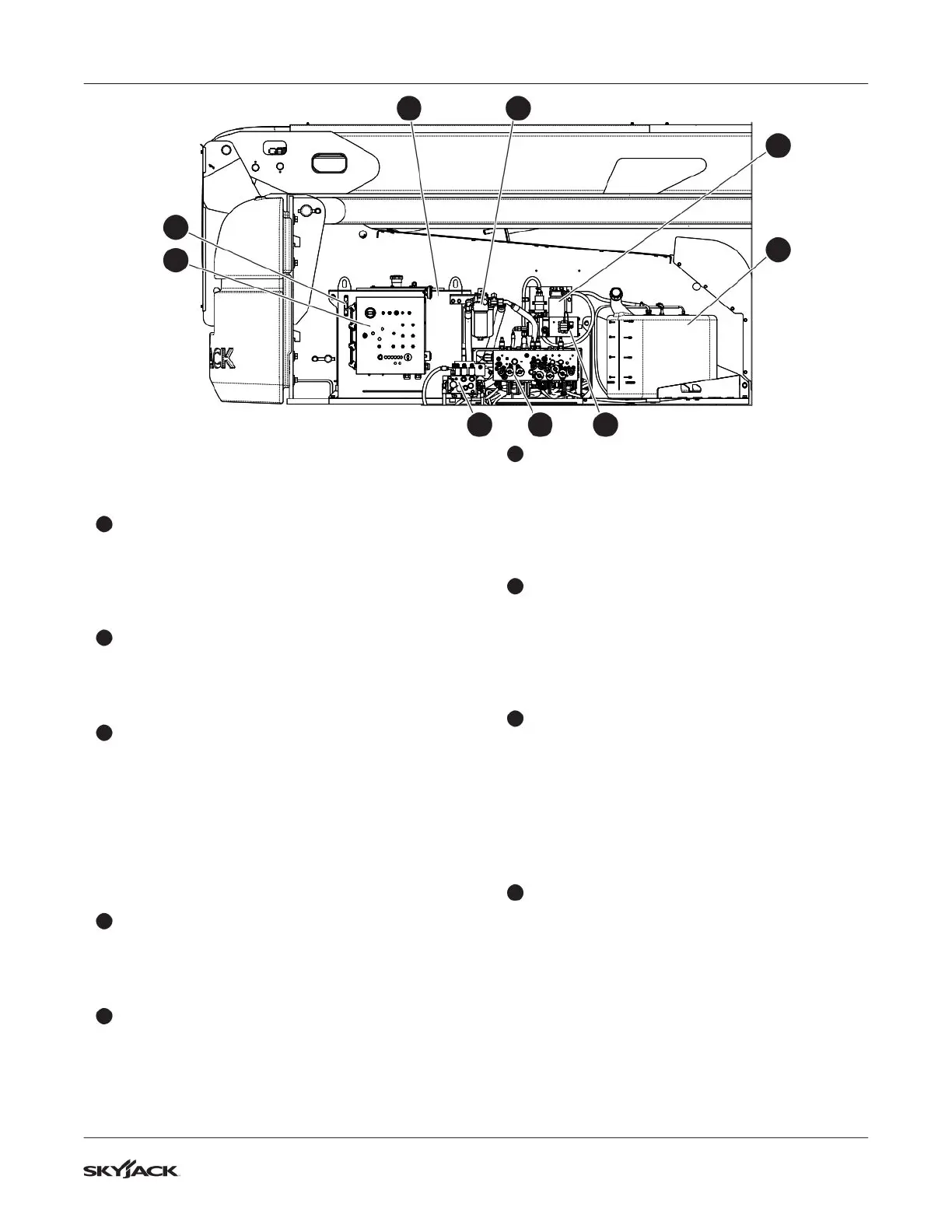

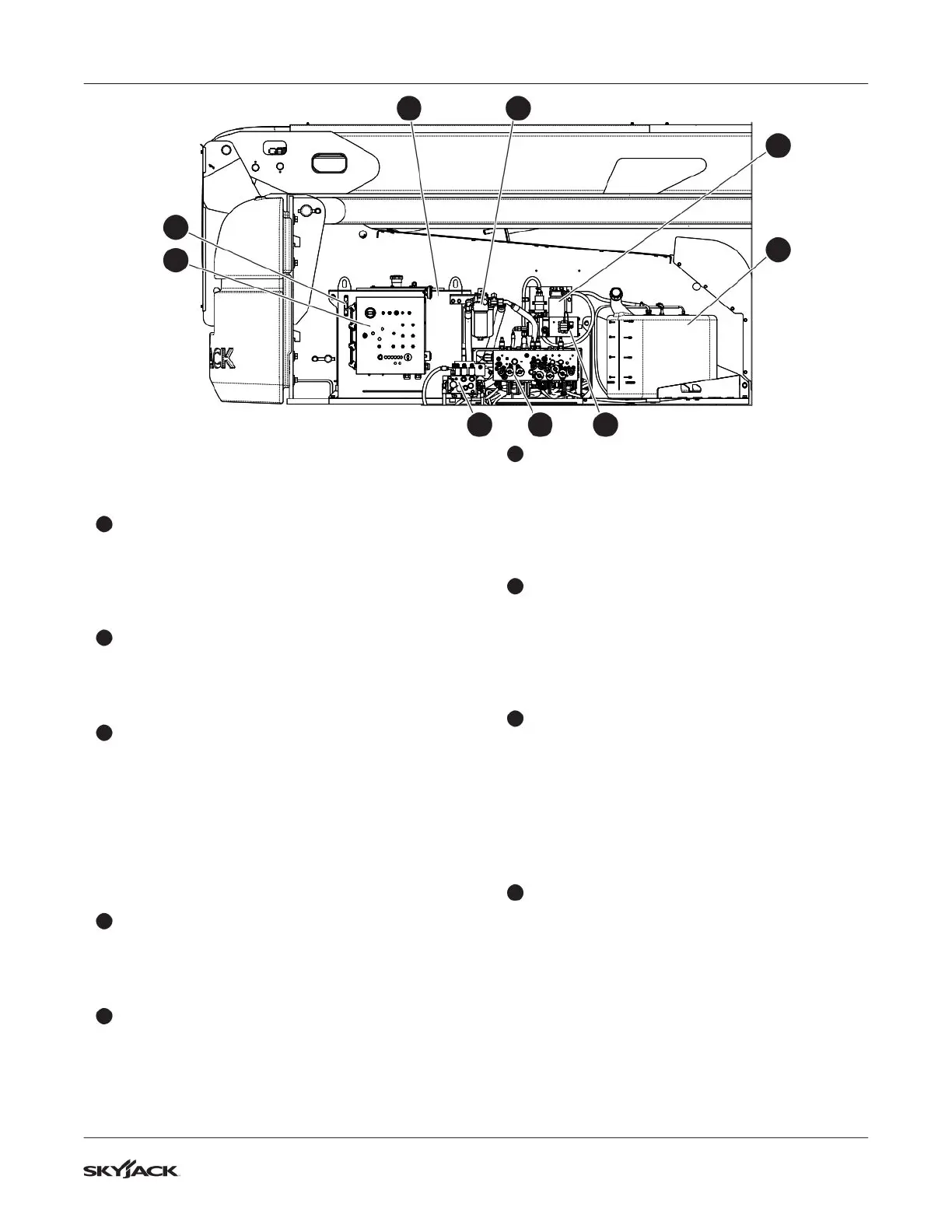

4.2-6 Control compartment

Ensure all compartment latches are secure and in

proper working order.

1

Base control console

▪

Ensure all switches are returned to their

neutral positions.

▪

Ensure there are no loose or missing parts and

there is no visible damage.

2

Hydraulic tank

▪

Ensure hydraulic ller cap is secure.

▪

Ensure tank shows no visible damage and no

evidence of hydraulic leakage.

3

Hydraulic oil level

▪

Be sure that the boom is in the stowed

position, and then visually inspect the sight

gauge located on the side of the hydraulic oil

tank.

▪

The hydraulic oil level should be between the

minimum and maximum marks on the sight

glass. Add oil as needed. Refer to service

manual for recommended oil type.

4

Hydraulic return lter

▪

Ensure lter element is secure.

▪

Ensure there are no signs of leakage or visible

damage.

5

High pressure lter

▪

Ensure housing is secure and shows no visible

damage or leakage.

6

Brake manifold

▪

Ensure all ttings and hoses are properly

tightened and there is no evidence of hydraulic

leakage.

▪

Ensure there are no loose wires or missing

fasteners.

7

Main manifold

▪

Ensure all ttings and hoses are properly

tightened and there is no evidence of hydraulic

leakage.

▪

Ensure there are no loose wires or missing

fasteners.

8

Emergency power unit

▪

Ensure there are no loose or missing parts and

there is no visible damage.

▪

Ensure there are no loose wires or missing

fasteners.

▪

Ensure all ttings and hoses are properly

tightened and there is no evidence of hydraulic

leakage.

9

Fuel tank

IMPORTANT

Before using your MEWP ensure there is enough

fuel for expected use.

▪

Ensure fuel ller cap is secure.

▪

Ensure tank shows no visible damage and no

evidence of fuel leakage.

1

2 4

5

9

876

3

Loading...

Loading...