Fitting a wheel

G

WARNING

Oiled or greased wheel bolts or damaged

wheel

bolts/hub

threads can cause the wheel

bolts to come loose. As a result, you could

lose a wheel while driving. There is a risk

of accident.

Never oil or grease wheel bolts. In the event

of damage to the threads, contact a quali-

fied specialist workshop immediately.

Have the damaged wheel bolts or hub threads

replaced/renewed. Do not continue driv-

ing.

G

WARNING

The wheels could work loose if the wheel

nuts and bolts are not tightened to the

specified tightening torque. There is a

risk of accident.

Have the tightening torque immediately

checked

at

a qualified specialist workshop

after a wheel is changed.

G

WARNING

If you tighten the wheel bolts or wheel nuts

when the vehicle is raised, the jack could

tip over. There is a risk of injury.

Only tighten the wheel bolts or wheel nuts

when the vehicle is on the ground.

!

When changing a wheel, use only wheel

bolts

that

have been approved for the wheel

rim and vehicle.

Fit tyres with a specified direction of rota-

tion only according to their direction of

rotation. An arrow on the sidewall of the tyre

indicates its correct direction of rotation.

X

Clean the wheel and wheel hub contact sur-

faces.

X

Push the wheel onto the wheel hub and press

it on.

X

Screw in the wheel bolts and tighten them

slightly.

X

Lower the vehicle all the way.

X

Remove the jack.

X

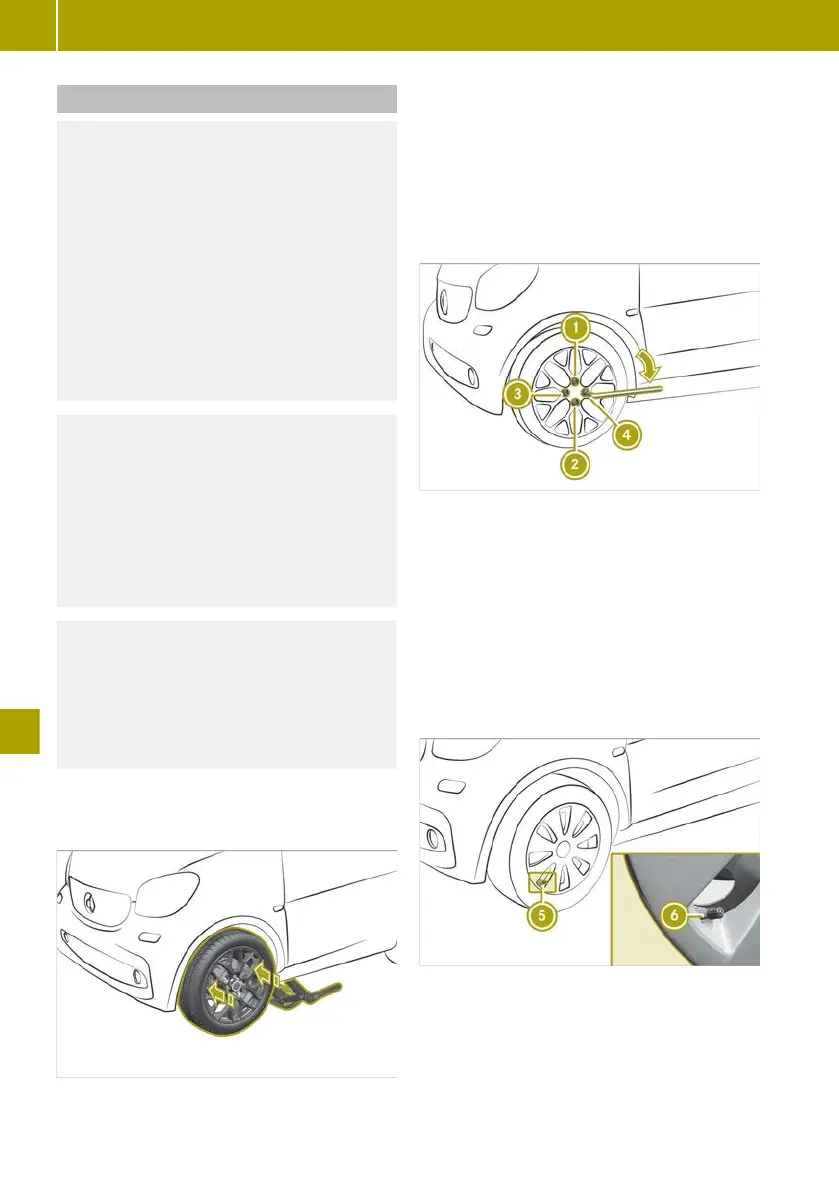

Tighten the wheel bolts evenly in a cross-

wise pattern in sequence indicated :

to ?. The tightening torque must be

105 Nm.

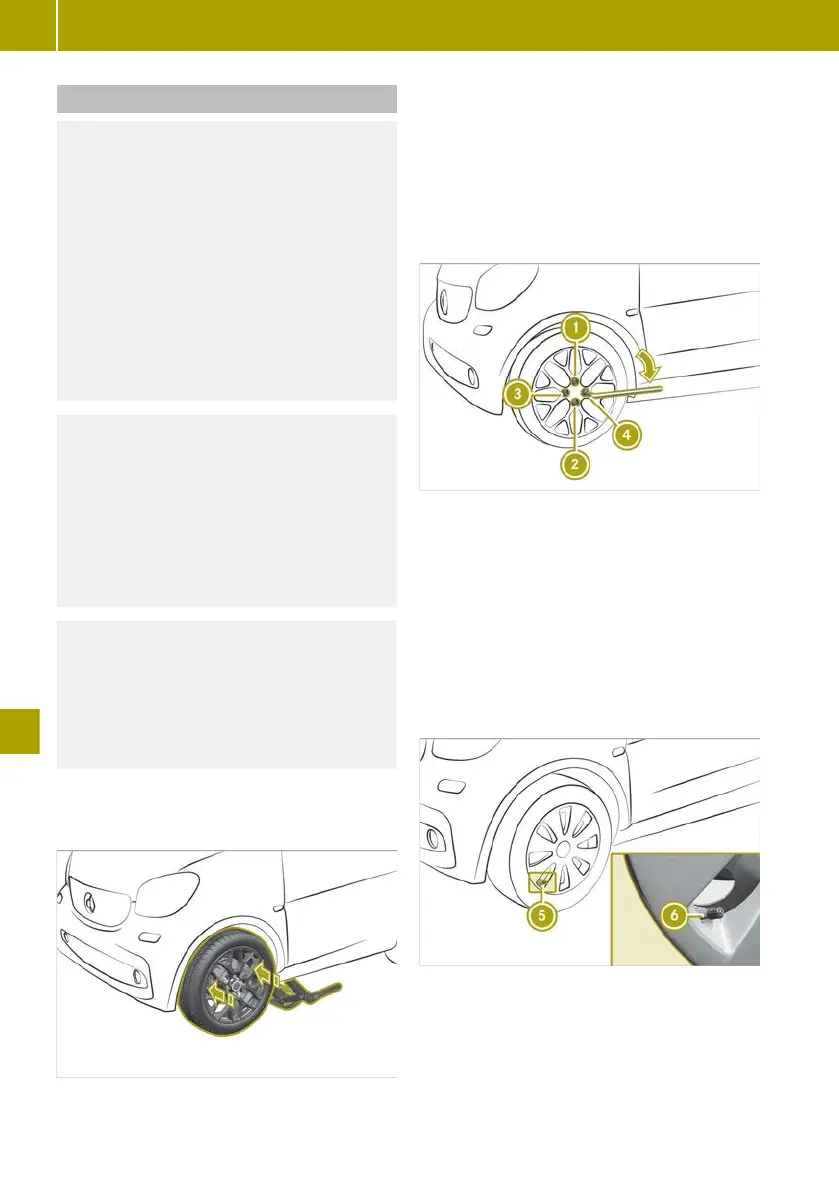

X

Check the recommended tyre pressure and

adjust if necessary.

i

Vehicles with tyre pressure control sys-

tem: all fitted wheels must be equipped

with functioning sensors.

Vehicle with steel wheels and hub caps:

134

Changing a wheel

>> Maintenance and care.

Loading...

Loading...