17 / 58

Use and maintenance manual BP700AR/310

ENGLISH

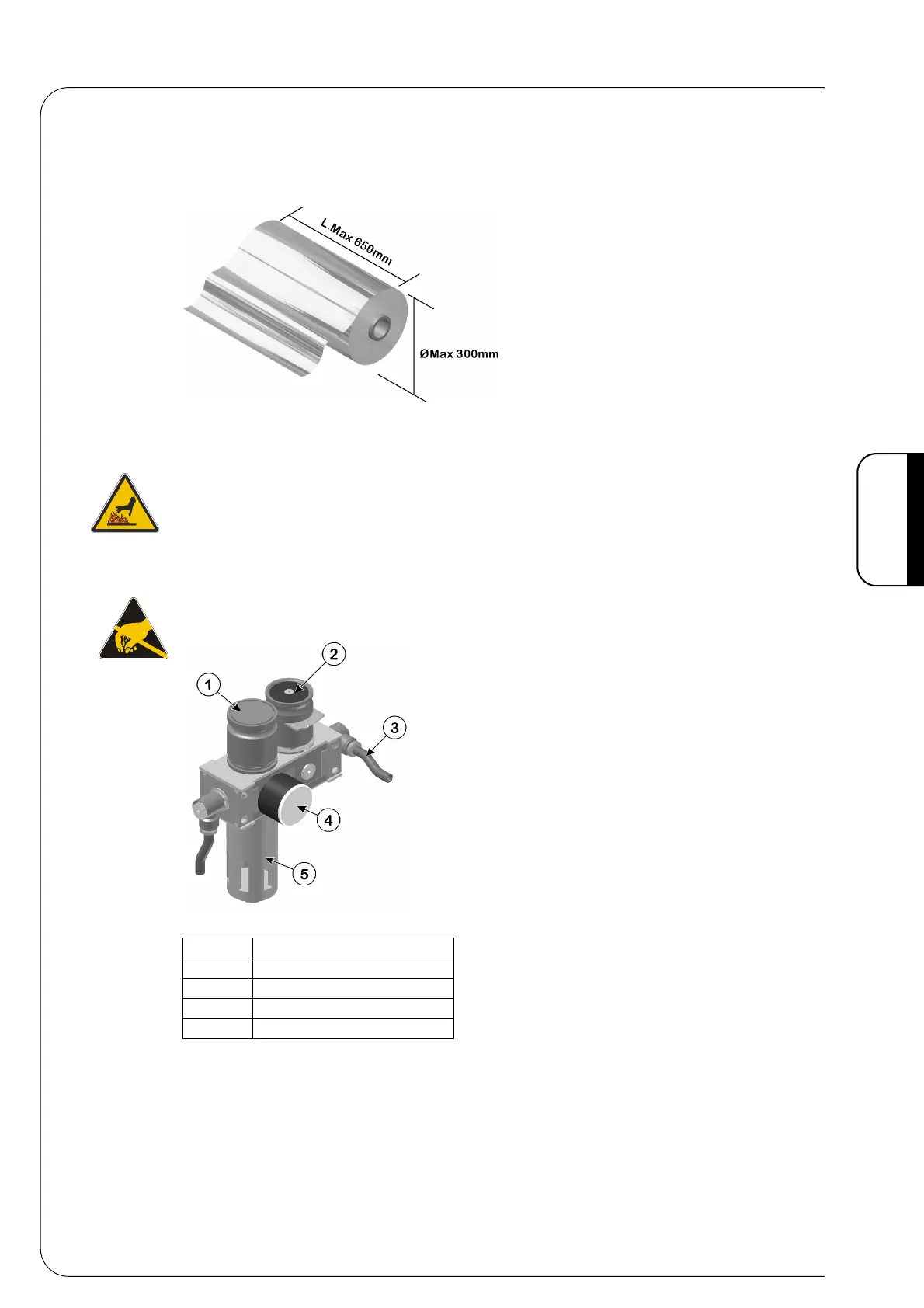

3.6 SHRINK-WRAPPING FILM CHARACTERISTICS

3.7 DANGEROUS AREAS

• Do not touch the sealing bar immediately after a sealing going beyond the protection barrier.

• Do not touch the film reel during the wrapping operation.

• Do not use the machine if there are any breakages to mechanical or electric members.

• Do not use the machine with protections open or disconnected.

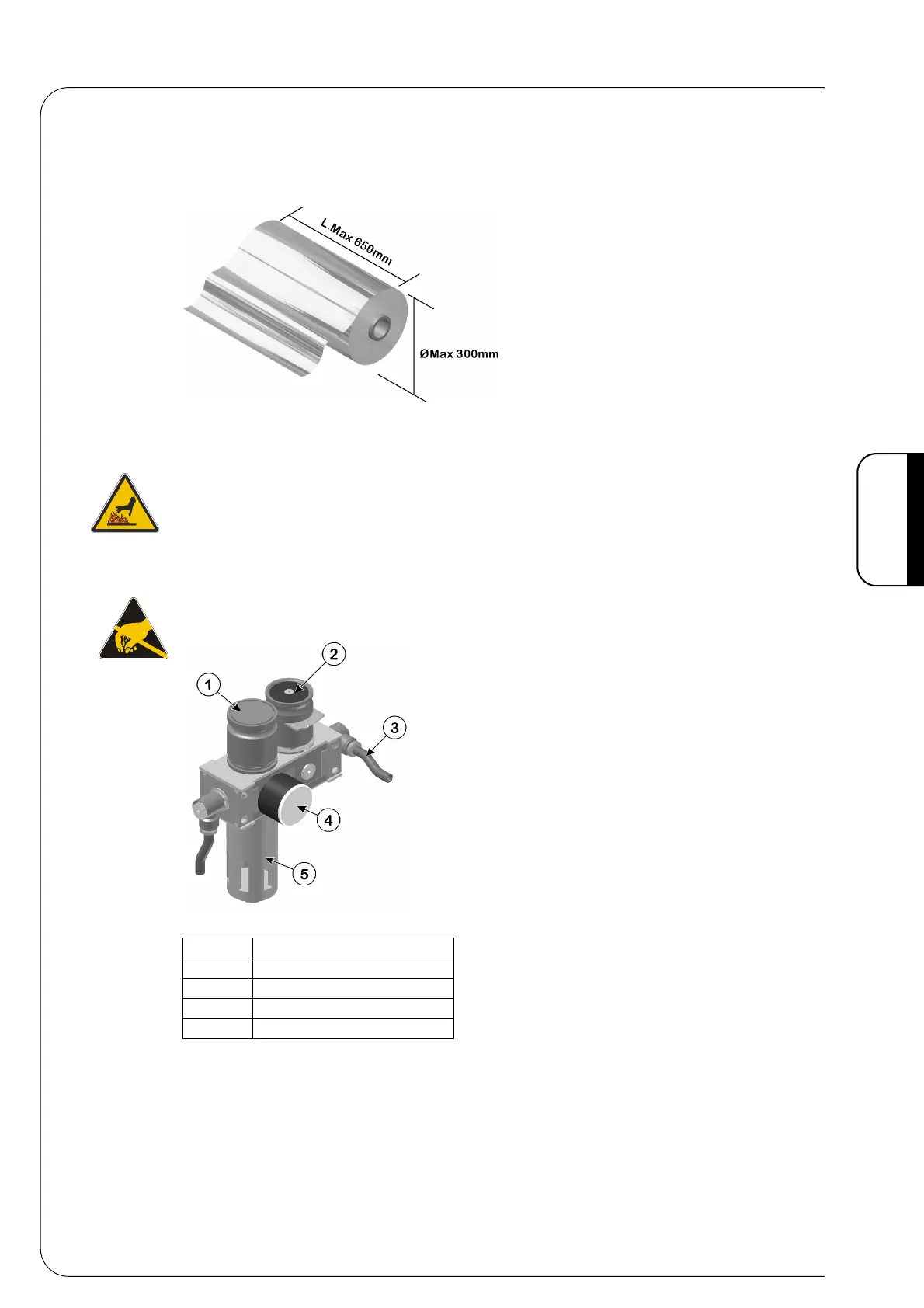

3.8 DATA FOR THE PNEUMATIC INSTALLATION

3.9 CHECKING FOR GOOD OPERATING CONDITIONS

1 • Belt section:

• Check the conveyor belts for possible damages.

• Check if the rollers are moving freely.

• Check that all the belts have a linear movement and that there are no breakages, tearing or

folds that can prevent the normal operation.

Fig. 3.6.1

The machine has been designed to obtain

the packaging of the most diversified

products, using a shrink-wrapping film

thickness of 40 and 100 µm.

Fig. 3.8.1

The air regulation pneumatic module composed of

a padlock valve and a regulator filter, with relative

pressure gauge used to regulate the air pressure in

the circuit. Pressing the push button placed above

the regulator 2 , rotate the handle grip so that air

flows inside the plant. Check the air pressure on the

pressure gauge 4.

For the connection, insert the air source into the

entrance link at Ø8 mm

Compressed aira:

• Working pressure: 5 Bar

• Max. consumption: 16 Normal litres/cycle

• Max. degree of impurity:

• solid particles: 40 µm. liquid particles: 0.5 PPM

1

Padlock valve

2

Regulator

3

Ø8 Power supply

4

Pressure gauge

5

Filter

Loading...

Loading...