55 / 58

Use and maintenance manual BP700AR/310

ENGLISH

7. ANOMALIES AND FAILURES - HOW TO REMEDY

7.1 POSSIBLE CAUSES AND REMEDIES

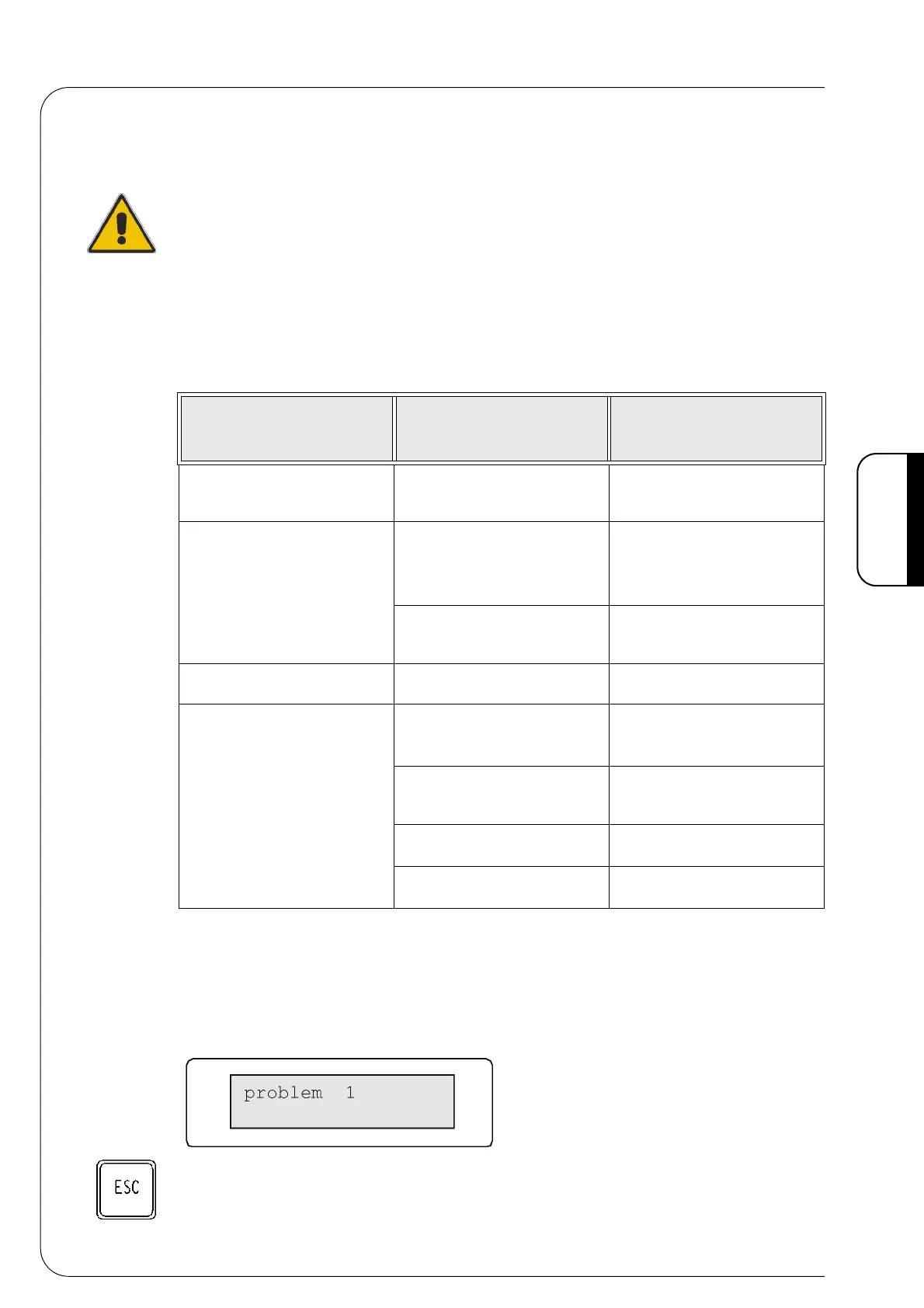

Following, the descriptions and relative solutions of common problems that could occur during

the normal operation of the machine.

ATTENTION!

All the checking and replacing operations on the machine, must be carried out without

voltage. In case of fire, use a CO2 exstinguisher. Avoid using powder extinguishers.

7.2 AUDIO WARNING OF PROBLEMS

Cyclically, the program performs a number of controls. If one of these controls has a negative

result, the system produces a "Beep" and a message showing the problem number.

Once the problem has been solved, it will be possible to exit this state by pressing the [ESC]

key.

Tab 7.1.1

PROBLEM: CAUSE

REMEDIES and

SOLUTIONS

SMOKE DURING SEALING

HIGH TEMPERATURE

REDUCE SEALING

TEMPERATURE

THE SEALING OPENS

DURING

SHRINK-WRAPPING

SEALING BAR DIRTY OR

DAMAGED

CLEAN THE SEALING BAR OR

REPLACE IT IF DAMAGED

WRONG SEALING VALUE

PLEASE ADJUST THE SEALING

VALUE

IRREGULAR SEALING

POOR QUALITY OF FILM REPLACE FILM

SEALING DOES NOT

TAKE PLACE

SEALING VALUE TOO LOW INCREASE SEALING VALUE

THE SEALING BAR DOES NOT

RECEIVE CORRECTLY

REPAIR THE RESISTOR INSIDE

THE SEALING BAR

WORN GASKET REPLACE THE GASKET

SEALING BAR DAMAGED REPLACE THE SEALING BAR

Fig. 7.2.1

Loading...

Loading...