27 / 58

Use and maintenance manual BP700AR/310

ENGLISH

5.5 ADJUSTING THE INFEED PRESS

Adjust the position of the press so that when it is open it is in line with the feeding bar and does

not obstruct the product that passes.

To adjust the pressure of the press, work on the gauge under the machine on the body side of

the belt. We recommend a pressure between 1.5 and 2 bar.

5.6 ADJUSTING THE PRESS

5.7 SETTING THE FEEDING BAR'S SPEED

To increase the hourly production you can set the feeding bar's speed.

Remove the cover 1 on the connecting belt by unscrewing the screws. Now work on the two

pressure regulators on the feeding bar's cylinder with a screwdriver. The regulator 2 allows you

to set the progress speed of the product while the regulator 3 allows you to set the return speed

of the feeding bar in the loading position.

ATTENTION!

A wrong adjustment of the counterweights could cause the following problems:

• The film does not flow on the tensioning bars and the product tips over.

• The film, being statically loaded, sticks to the reel.

The sealing could occur in a non optimal position for correct packaging.

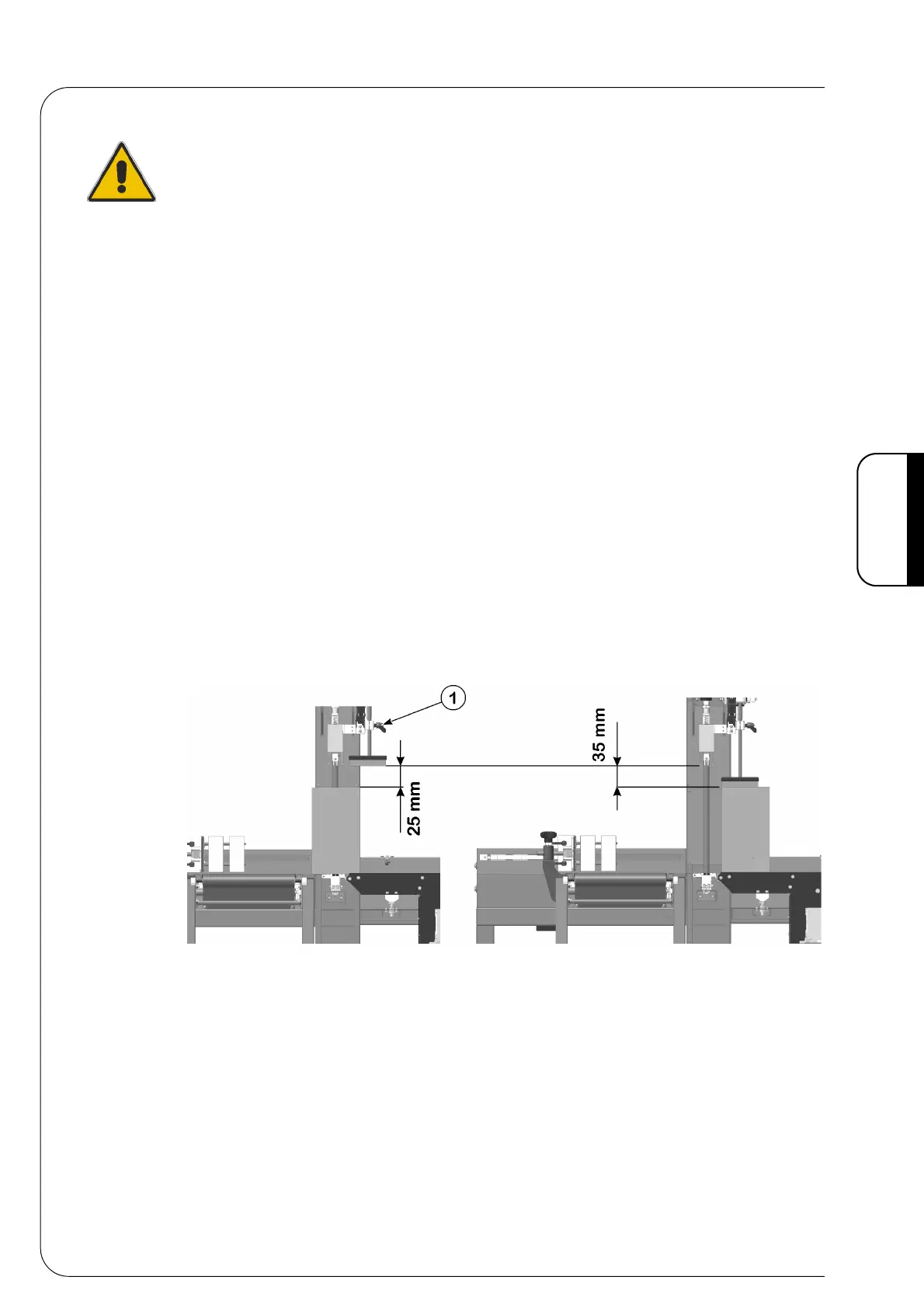

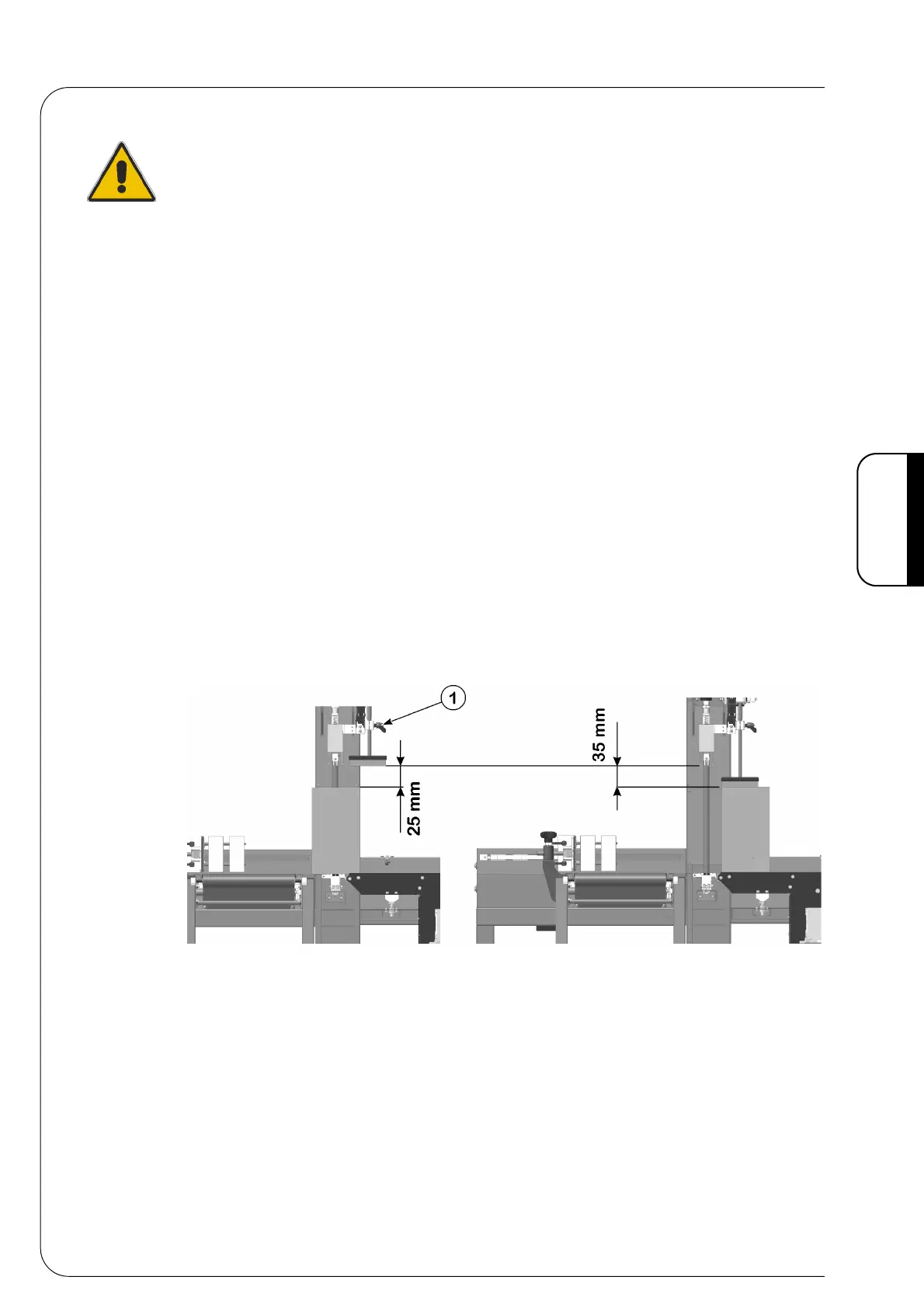

Working on the handle 1 adjust the height of the press in comparison to the product .This

height must be about 25/30mm so that, during the cutting and sealing operation, it goes down

onto the product holding the film pressed. The stroke of the presser cylinder is 35mm.

1 • Product in movement

In this phase the product passes from

the working surface to the conveyor belt

between the shrink wrapping packer and

tunnel

2 • Sealing position

The product stops on the belt and is

blocked by the press. The edges are

then sealed and cut.

Fig. 5.6.1

Loading...

Loading...