30 / 58

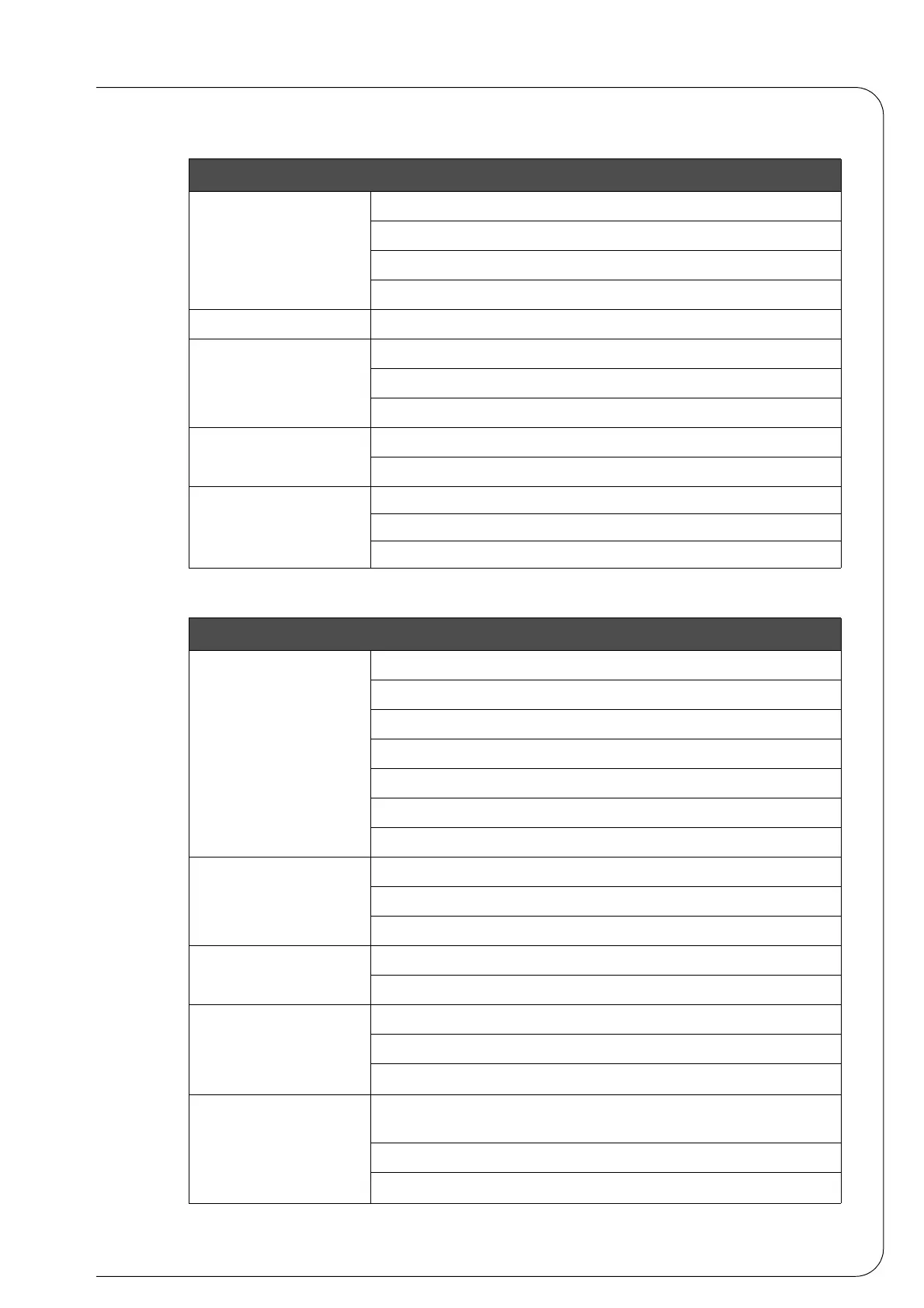

Tab. 6.1.3

MONTHLY MAINTENANCE CHART (240 HOURS OF WORKING)

SEALING UNIT

MAKE SURE THAT THERE ARE NO BREAKAGE ON THE CUTTING BLADE

CHECK THE WEARING STATE OF THE SILICON RUBBER

CLEAN AND GREASE THE GUIDES

MAKE SURE THAT THE PNEUMATIC PARTS ARE WORKING CORRECTLY

PROTECTIONS

CLEAN THE SWITCHES AND THE EMERGENCY SAFETIES

CONVEYOR BELT UNIT

TIGHTEN AND ALIGN THE BELT

CHANGE THE BELT IF IT IS WORN

CHECK THE SCREWCOUPLING

TENSIONING RODS

CLEAN THE ROLLERS OF THE TENSIONING RODS

MAKE SURE THAT THE TENSIONING RODS ARE MOVING CORRECTLY

INFEED CONVEYOR

BELT

MAKE SURE THERE ARE NO BREAKAGE ON THE CONVEYOR BELT

USE SOFT CLOTHS TO DRY THE MACHINE IF IT IS STILL WET

CHECK FOR POSSIBLE ANOMALOUS NOISES

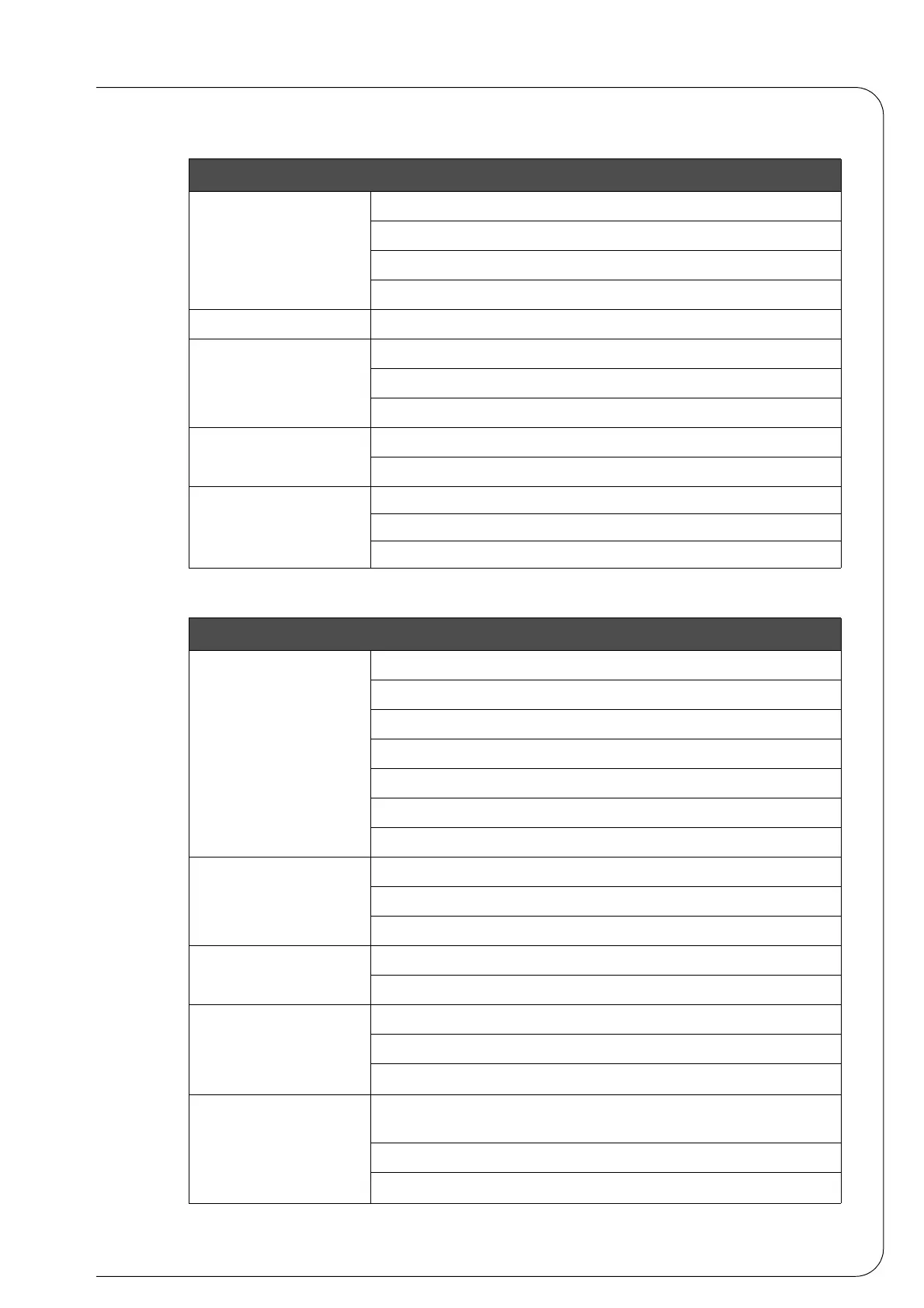

Tab. 6.1.4

HALF-YEAR MAINTENANCE CHART (1500 HOURS OF WORKING)

SEALING UNIT

CHANGE THE SEALING BLADE

CHECK THE WEARING STATE OF THE SILICON RUBBER

CHECK THE SPRINGS OF THE SEALING BAR

CHECK THE SPRINGS OF THE SEALING CONTRAST

CLEAN AND GREASE THE GUIDES

CHECK THE SENSORS

MAKE SURE THAT THE PNEUMATIC PARTS ARE WORKING CORRECTLY

BELT UNIT

MAKE SURE THAT THE BELT IS WORKING CORRECTLY

CHECK FOR ANOMALOUS NOISES

REPLACE POSSIBLE DAMAGED PARTS

PUSHER DEVICE UNIT

MAKE SURE THAT THE PUSHER DEVICE IS SLIDING PERFECTLY

CHECK THE PNEUMATIC PARTS

CONVEYOR BELT

MAKE SURE THERE ARE NO BREAKAGE ON THE CONVEYOR BELT

MAKE SURE THAT THE CONVEYOR BELT IS WORKING PERFECTLY

CHECK FOR POSSIBLE ANOMALOUS NOISES

CONNECTING

CONVEYOR BELT

CHECK THE WEARING STATE OF THE SILICON RUBBER

MAKE SURE THAT THE PNEUMATIC PARTS ARE WORKING CORRECTLY

CHANGE DAMAGED PARTS

Loading...

Loading...