Maintenance Waukesha Cherry-Burrell

Page 40 95-03080 12/2010

20. Install the original shims on the motor adapter shaft.

21. Install the backplate with the seal assembly and impeller on

the motor shaft.

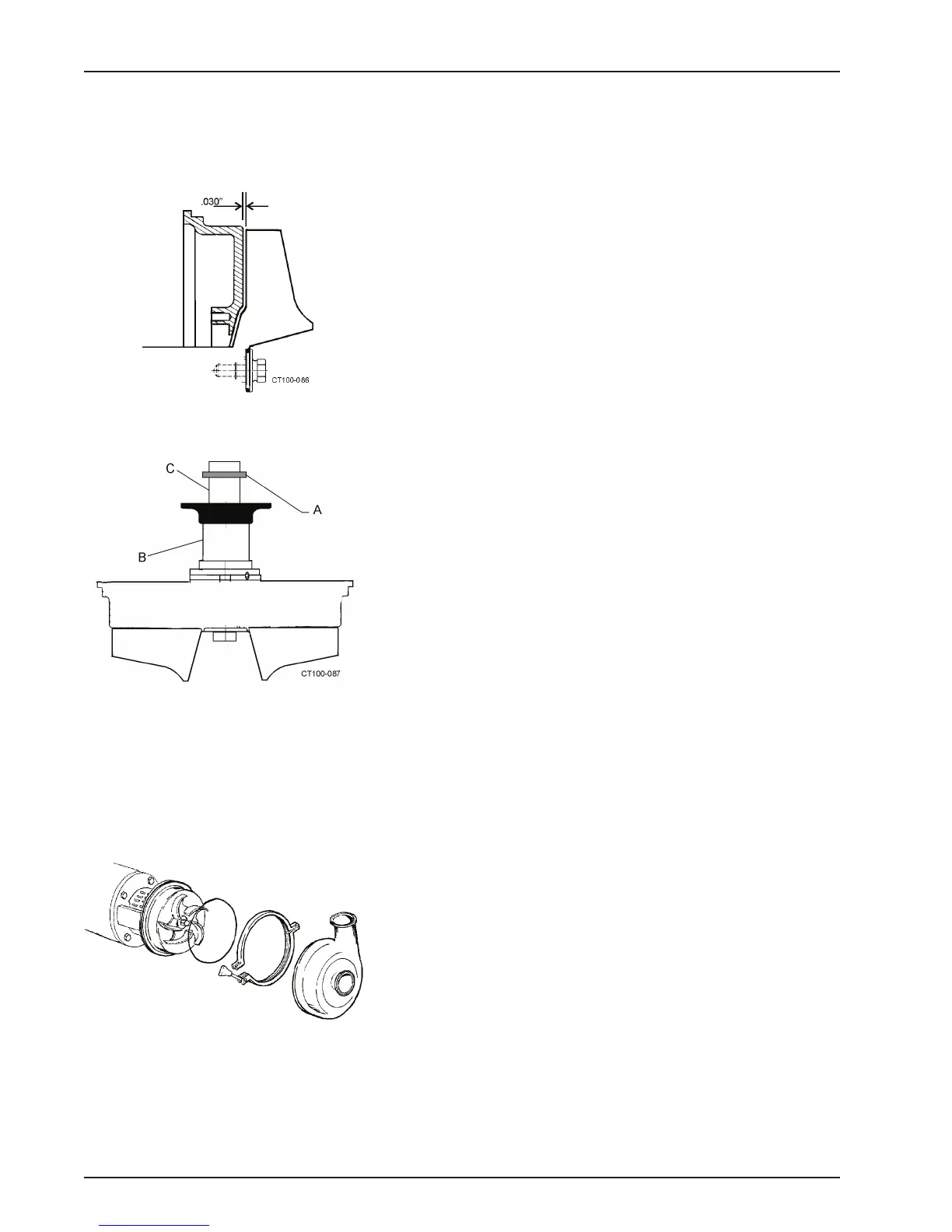

22. Check the impeller/backplate clearance with the backplate

held firmly in position against motor adapter. Check the

space between the back of the impeller and the backplate

with a feeler gauge (.030 nominal) while holding the back-

plate tight against the bearing housing flange. (Any axial

mo

vement of the shaft should not be added to the .030 nomi-

nal clearance). See Figure 44.

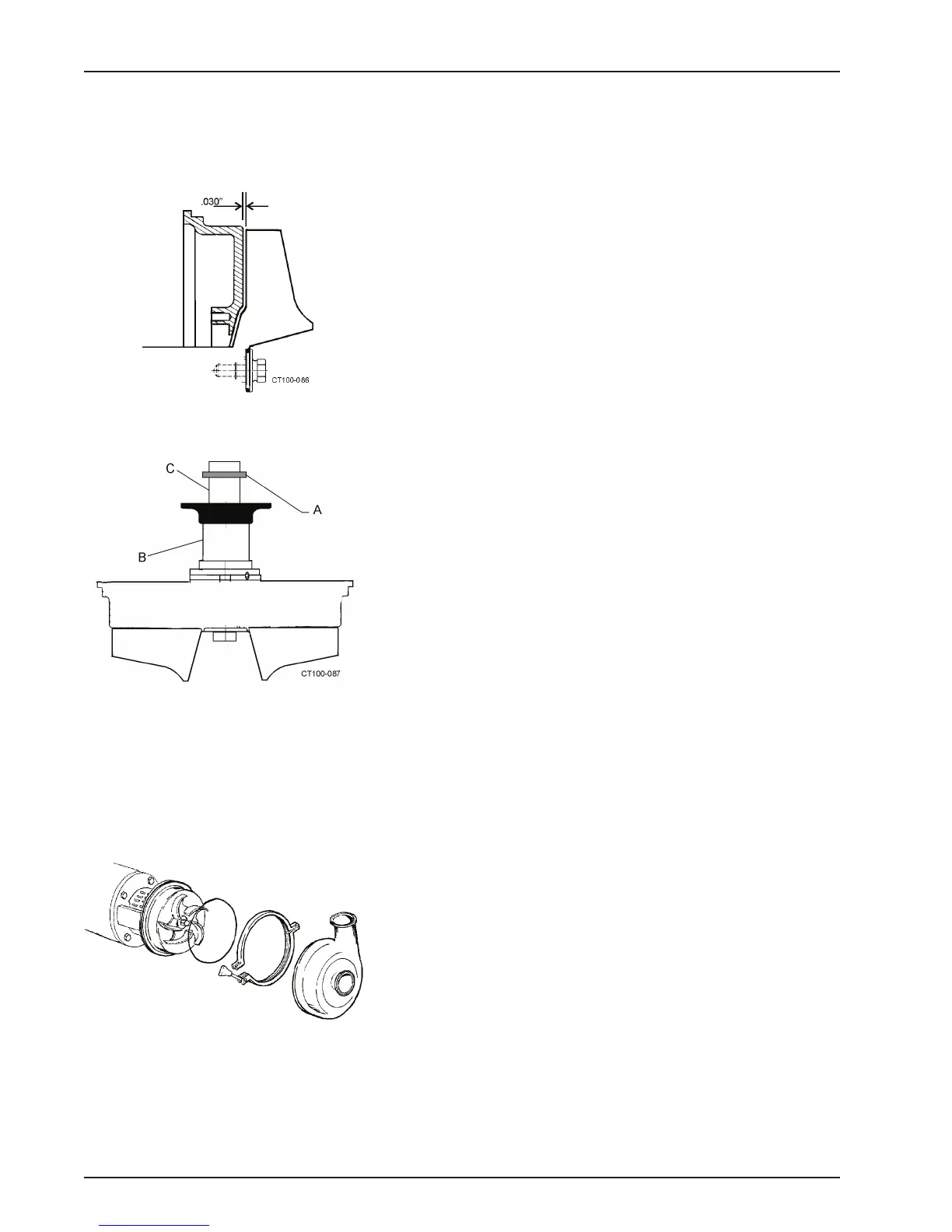

23. If needed, change this clearance by adding or removing

shims. Shims (Figure 45, itemA) can be added on the drive

shaft (Figure 45, item C) behind the impeller shaft (Figure 45,

item B).

24. Confirm operating clearances by cla

mping the casing to the

bearing housing flange and rotating the shaft/impeller manu-

ally to be sure the impeller does not touch the casing or back-

plate.

25. Tighten the set screws in the spring retainer through the 1/4

NPT ce

nter port in flush housing (Figure 41, item N).

26. Insert the plug in the port and tighten.

27. Remove the backplate/impeller assembly, apply anti-seize or

equal compound to the mot

or shaft, and install the key.

28. Install the backplate/impeller assembly and lock it in place

usin

g the o-ring and impeller retainer bolt.

29. Install the casing o-ring on the backplate and clamp the cas-

ing in place. See Figure 46.

NOTE: Rotate the impeller

manually to ensure that it does not rub

on the backplate or casing.

Figure 44 - Clearance Between Impeller

and Backplate

Figure 45 - Locations of Shims

Figure 46 - Install Casing

Loading...

Loading...