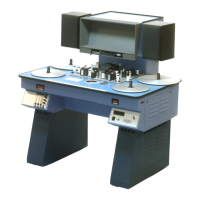

V01-2013 35mm-01 serie

20

8.2 Replacing the picture lamp.

The interchangeable condenser system (fig. 5 #55 page11 ) encloses

the picture lamp.

Remove both nuts besides the system and remove carefully the system.

Take out the lamp and the new one is carefully and gently pressed into the lamp

socket.

ALWAYS readjust the newly inserted picture lamp.

NEVER touch the bulb with your fingers or clean it with a chemical alcohol.

Replace the condenser system carefully and pay attention to the contacts in the

ground plate and the female contacts in the drive deck.

8.3 Replacing of exciter lamp / optical sound lamp.

Remove protection cap (fig. 5 #46 page 11), loosen screw behind exciter lamp,

Before taken out the broken exciter lamp, check how it was placed. (lamp filament)

Take out old exciter lamp.

Replace new lamp the same as the broken came out.

Turn it in order to gain maximum illumination through the light gap, which is tested by

running film with optical sound.

Now tighten screw gently and put protection cap on.

8.4 Adjustment of pressure arms picture.

Feed two films strips through the sprocket and counter press arms.

Loosen screws at the bearing shaft plate (#53 – page 23) and change pressure of the

arm so that both guide rollers are under the same pressure. Now tighten screws.

Loosen fixing screws of locking pin. Turn it, so that there is no play between film and

guide roller. Tighten fixing screws.

As pressure arms are adjusted for two thicknesses of film by manufacturer,

readjustment is only necessary after dismantling of the bearing shaft or the locking

pin.

Maintenance of optical parts.

8.5 Surface-coated mirrors.

Cleaning may only be done with a soft lens brush or lens cloth.

If the mirror is very dirty, detach it and clean carefully with clear water and cotton

wool. To avoid water stains the final touch is made with dry cotton wool.

8.6 Polygon and lens.

If the polygon is just a slightly soiled, open the pressure arms from the front and

clean with soft leather, cotton or special optician’s tissue.

For more thorough cleaning the support of the upper film guide support can be

removed (fig. 5 #34 page 11)

For this purpose remove at first the cap from the objective and prism (fig. 5 #52), than

loosen the 4 screws of the support and the upper film guide support can be taken off.

One has free access to the polygon now,

When remounting the support be sure the surface of the base is clean, otherwise the

upper film guide and sprocket ring do not line up.

The objective and prism can only be cleaned with the housing removed.

This should done by an Steenbeck engineer only because of optical alignment of the

projected image.

Loading...

Loading...