V01-2013 35mm-01 serie

21

8.7 Screen.

The surface of the synthetic material is sensitive and can easily be scratched.

It is advisable to clean the screen regularly with a soft close.

If more cleaning becomes necessary, unscrew the screen from the screen holder

(fig.1 #11) and clean it with water.

Caution: -do not used any chemicals.

-pull the counter flat cable plug before removing the screen (holder).

8.8 illumination system.

The upper prism and its lenses (interchangeable condenser #55 – fig. 5 page 11)

can be unscrewed and cleaned in the same manner as the revolving prism (polygon).

See 8.5 – 8.6.

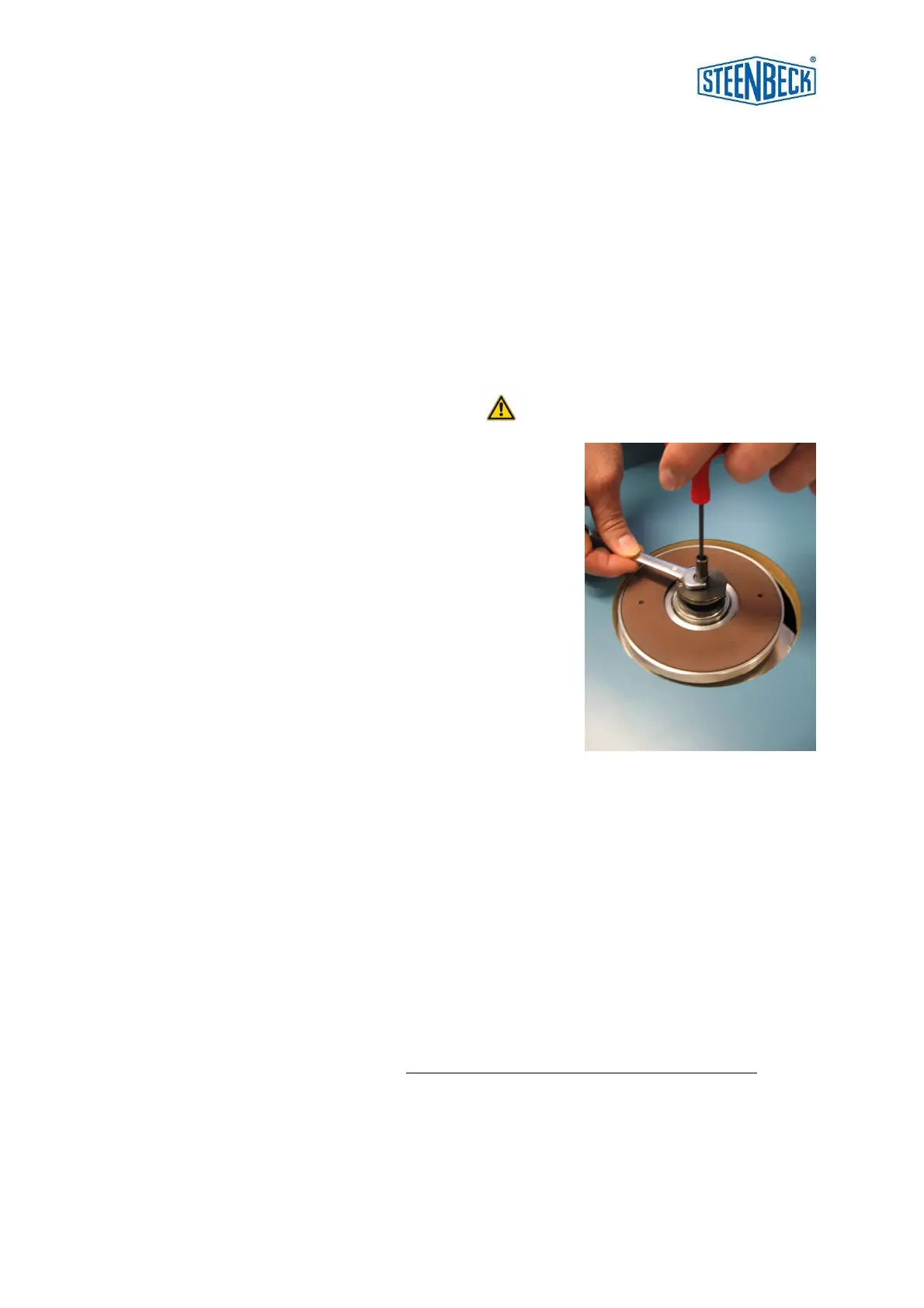

8.9 Frictions. (take up and supply units)

Frictions are operated by a motor via multiple V-belts.

It may become necessary to adjust the belt tension

after a certain operating time.

To achieve this, open frame on both sides and loosen

the corresponding tension roller arms with a wrench for

5mm bolts (8mm) and adjust the belt tension.

The wind pull of the centre cores can be adjusted with

the little tension bolt inside the square mandrel (8mm)

of each friction.

For readjustment take off the film core. The tension bolt

can be turned then by an allen key (hexagon) 2.5mm

Steenbeck part number 9962.0088.00.

When turning anticlockwise the wind pull will be more

firm.

When turning clockwise the wind pull becomes looser.

The square 8mm mandrel must be arrested with a 8mm wrench.

(Steenbeck part number N000.0471.00 )

The wind pull should be checked by means of a 100 core and a spring scale.

In running mode (sync) of the table it should be as follows:

35mm picture: approx. 1.0 – 1.2 N / 100 – 120 grams.

35mm sound: approx. 0.8 – 1.0 N / 80 - 100 grams.

Caution: this is an advise and other adjustments should be made regarding old,

shrunken or twisted material.

The core plate of the friction should not be greased or lubricated at the bottom.

The core axle fig.a should be greased a little bit.

The film plate support fig.b (plastic ring friction plate / inner ring film plate fig.c)

should have some Vaseline. (Steenbeck part number N000.0472.00)

Loading...

Loading...