V01-2013 35mm-01 serie

22

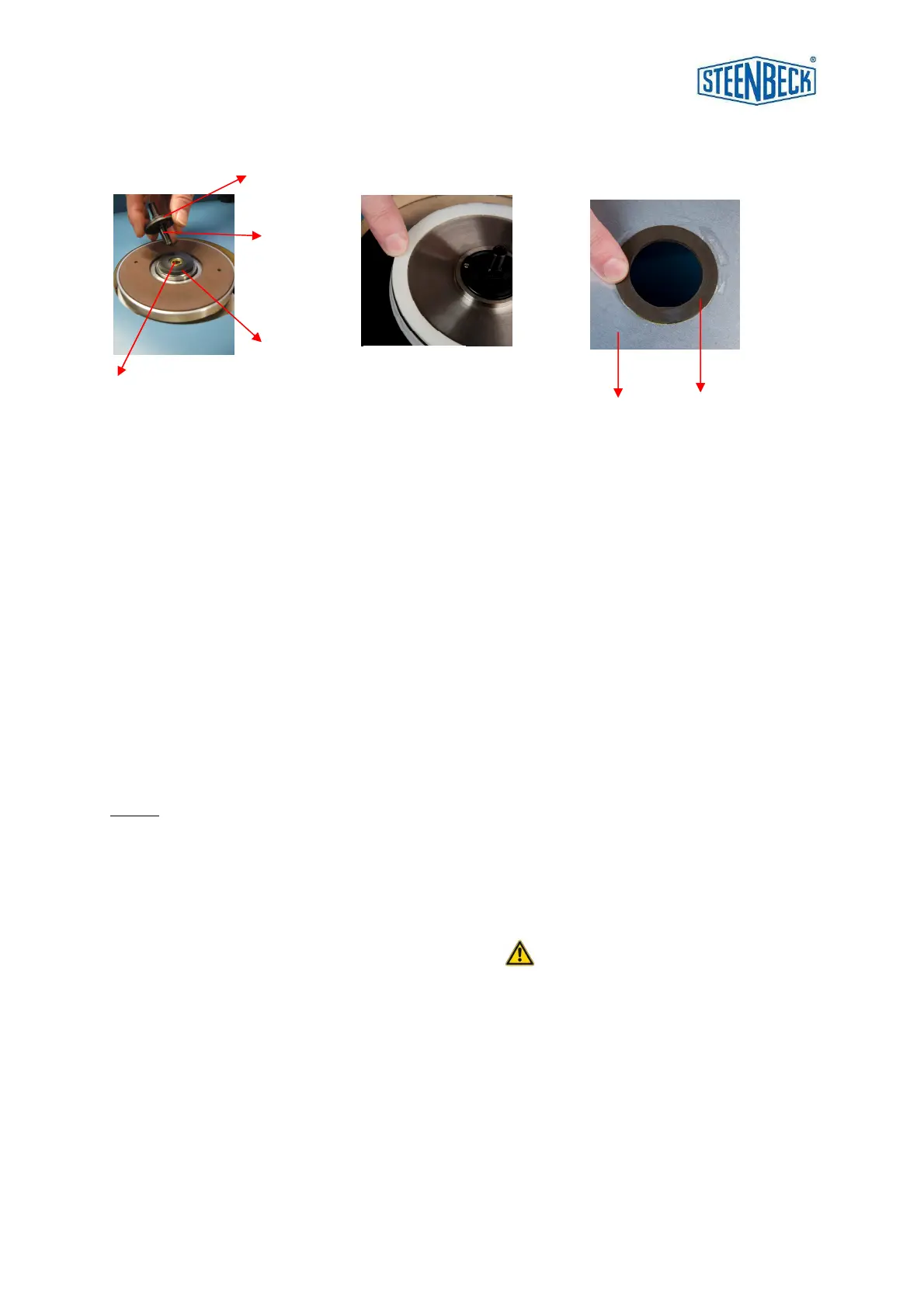

fig. a

core friction axel

core axel

friction disc

core plate

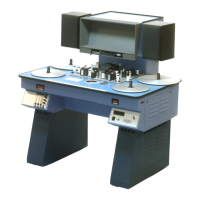

fig. b

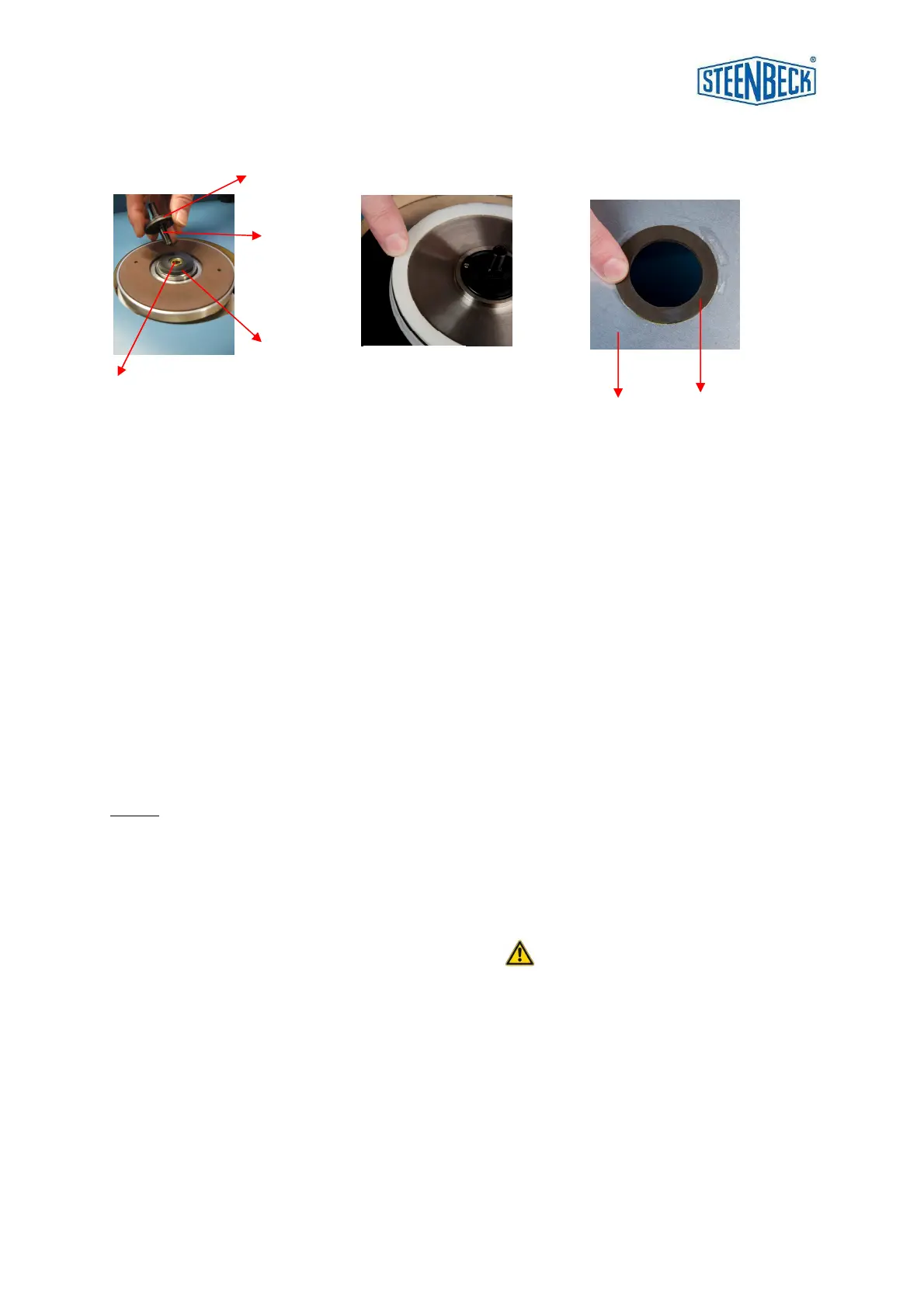

fig. c

film plate

inner ring

If metal film reels are used, the film plates and film core holders have to be taken off.

The film reel is then placed upon the remaining square mandrel.

This is only for 16mm film reels according ANSI PH 22.11 – 1981).

You might have to readjust the frictions because the weight of the film reels (see

above).

Caution: do not use a film reel with a core diameter less than 50 mm, as otherwise

the film material could be damaged.

8.10 General maintenance.

Remove dust, scrapping and film remainders from the machine DAILY.

After every approx. 100 hours of operation:

Clean all guide rollers, pressure arms/rollers and sprockets from possible remainders

of film and tape.

For cleaning the teeth of sprockets use a wooden stick.

Never use steel tools.

After every approx. 500 hours of operation:

Take off all rollers, clean rollers, shaft of rollers and axles with cleaning solvent.

Grease slightly the axles and shaft with a highly fluid oil.

After every approx. 1000 hours of operation:

Change motor oil in gear box as follows:

-open the middle panel of the chassis.

(near your knees when sitting behind the table)

-look for the drain screw at the bottom and the filling screw at the top of the gear box.

Loosen both screws. Empty the old oil into a container.

After tightening of the drain screw refill the box with new oil ATF, approx.. 22cc.

An elapsed time counter is available as an option. (Z50)

plastic ring

Loading...

Loading...