46

EN

6�2�1 HPL Machine Table

The HPL machine table with aluminum T-slots consists of a single HPL panel with 8 mm thickness and is stabilized by

crossbars. Various materials can be xed on the table by use of the supplied clamping bars. It is easy to clean and offers

a resistant surface.

6�2�2 Aluminum T-Slot Table (optional)

The 12 mm (D.420 and D.600) or 15 mm (D.840) thick T-slot table is made of low-stress aluminum and is suitable for

xing all sort of types of workpieces or accessories, such as vises, rotary tables, stops, prisms and angles. It is suitable for

use with the MDM lubrication system as well as dry applications. The T-slots are suitable for hexagonal M6 screw heads

or slot nuts up to 10 mm wide. This table replaces the HPL machine table.

6�2�3 Vacuum Table PE (optional)

With the vacuum table PE, workpieces can be xed by negative pressure. Due to the high-grade plastic PE500, the table

is particularly robust and suitable for use with the MDM lubrication system as well as dry applications. This clamping

method allows top machining as well as through-milling, and the processing of larger plates. The vacuum must be gener-

ated by means of an industrial vacuum cleaner (or similar). This table replaces the HPL machine table.

6�2�4 Vacuum Table MDF (optional)

With the vacuum table MDF, workpieces can be xed by negative pressure. This clamping method allows top machining as

well as through-milling, and the processing of larger plates. This table is suitable for dry work applications. The vacuum

must be generated by means of an industrial vacuum cleaner (or similar). This table replaces the HPL machine table.

6�3 Clamping a Workpiece

The workpiece can be secured directly on the machine table using clamping devices such as the Clamping Set (EU Item

10063, US Item 10063). If you want to mill through the material and produce cutouts, we recommend the use of a

suitable material as spoil board. The workpiece should be sufciently clamped to prevent it from unintentional movement

during processing. The maximum workpiece size results from the maximum clamping length and width:

Use clamps or another practical and secure way to x the workpiece on the machine table, e. g. with the

help of a vacuum table, double-sided tape or clamps. Holding a workpiece with your hands leaves it unsta-

ble and may lead to loss of control or serious injury.

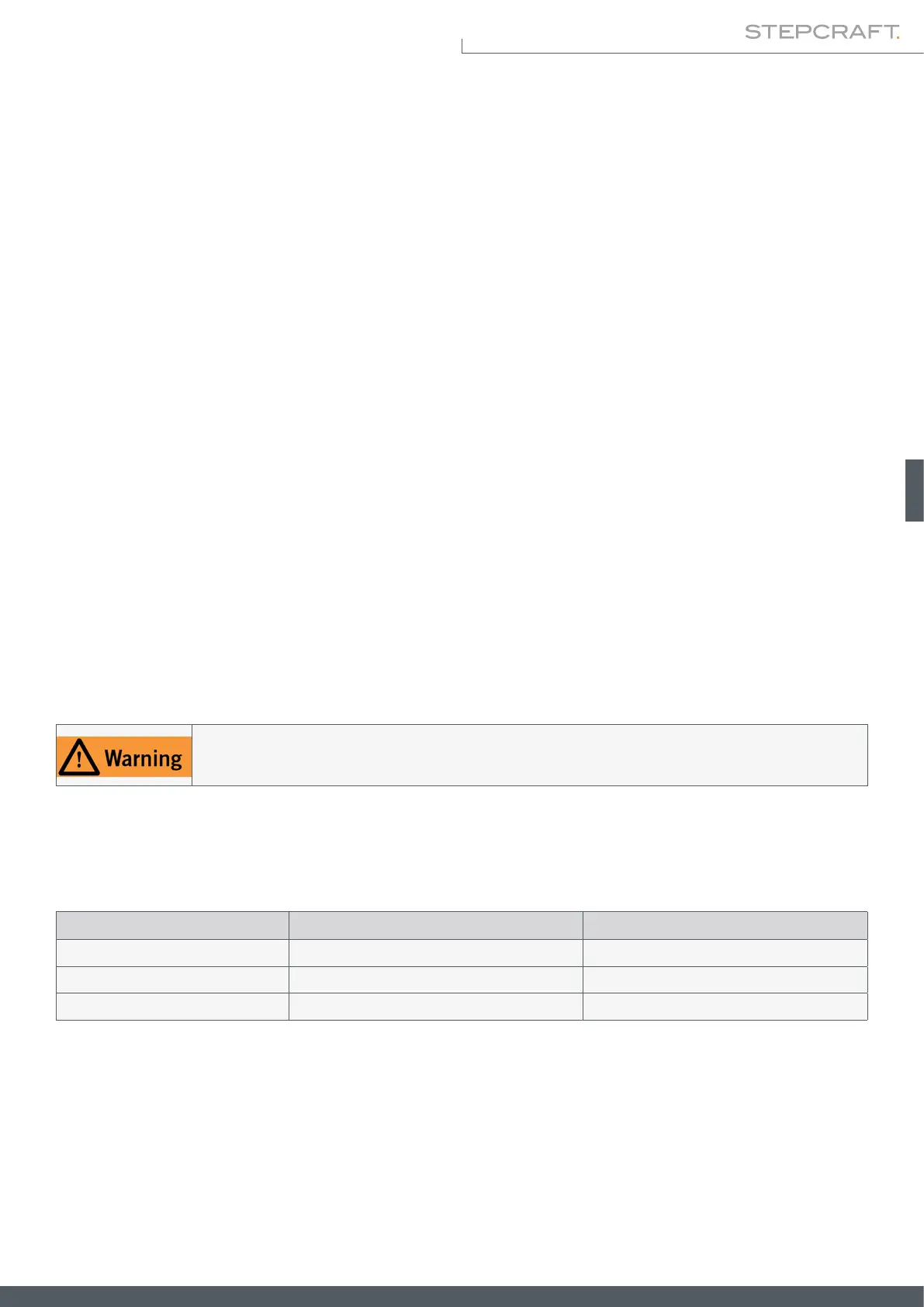

Machine Clamping length Clamping width

D.420 499 316

D.600 679 436

D.840 920 616

6�4 Operation of the CNC System

The entire CNC system is controlled and operated via computer. The operator must have completely read and understood

the entire documentation of the CNC control software before commissioning the CNC system. For further questions re-

garding the applied control software, please contact the respective software manufacturer.

Loading...

Loading...