51

EN

9�2�1 Information on Lubrication of Lead Screws / Guides

To improve smooth running operation and reduce noise,

we recommend regular lubrication with machine grease

and a low-viscosity oil. We recommend the use of

STEPCRAFT machine grease (Item 10050) and special

oil (Item 12398). After maintenance, you should move all

axes repeatedly from the foremost to the rearmost position

to distribute the lubricant evenly.

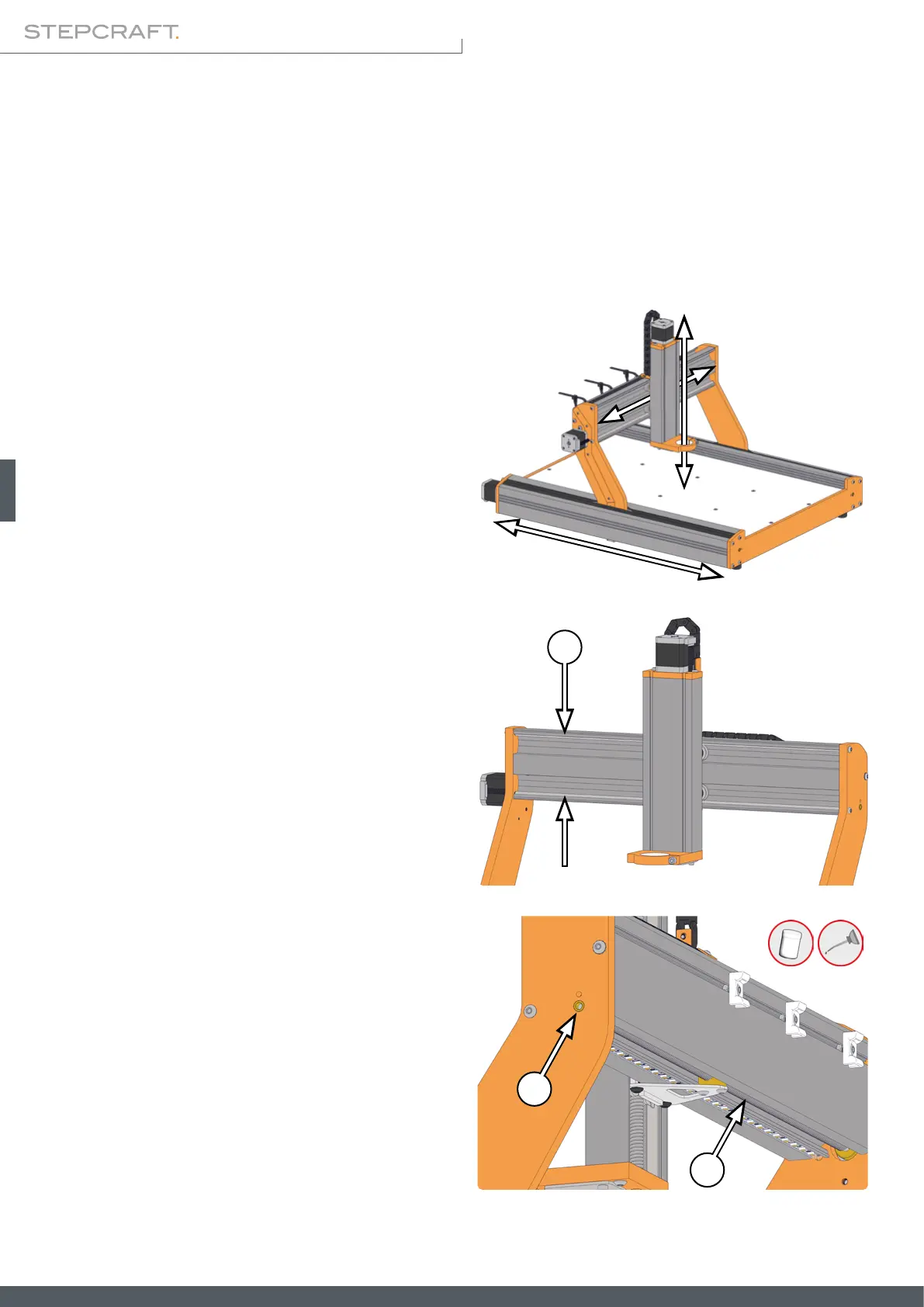

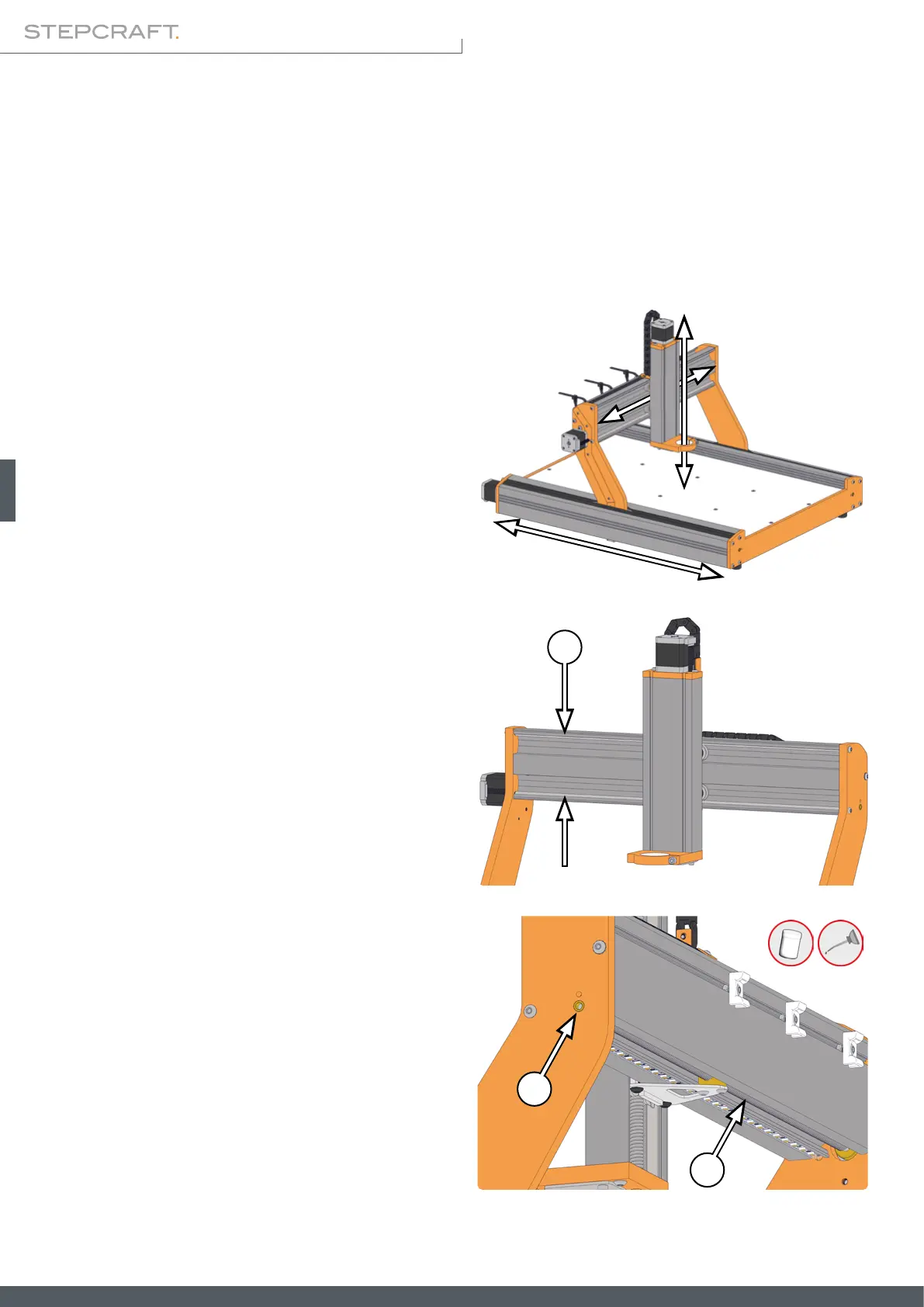

9�2�2 X-Axis

The leadscrews and steel guides must be checked regular-

ly, cleaned of dirt and relubricated, if necessary.

Move the X-axis to the most left position. Use a cloth to

remove dirt from the steel guides (1) and the X-axis lead

screw (2).

Then use a brush or cloth to evenly distribute grease on

the steel guides and the lead screw.

Move the X-axis to the rightmost position and repeat the

cleaning and lubrication procedure accordingly.

Finally, add a small amount of oil to the ange sleeve (3)

on both sides of the X-axis.

9�2 Recommended Maintenance Work

The STEPCRAFT D-Series should be serviced at regular intervals. The frequency depends on your individual use. To

ensure that you enjoy your CNC system for a long time, please treat it with care. Regular maintenance has a decisive

inuence on the service life of your machine. Regularly free the CNC system from chips and other production residues.

We recommend using a compressed air gun and also the STEPCRAFT cleaning set (Art. 12391).

3

2

1

Loading...

Loading...