26 MS 461, MS 461-R

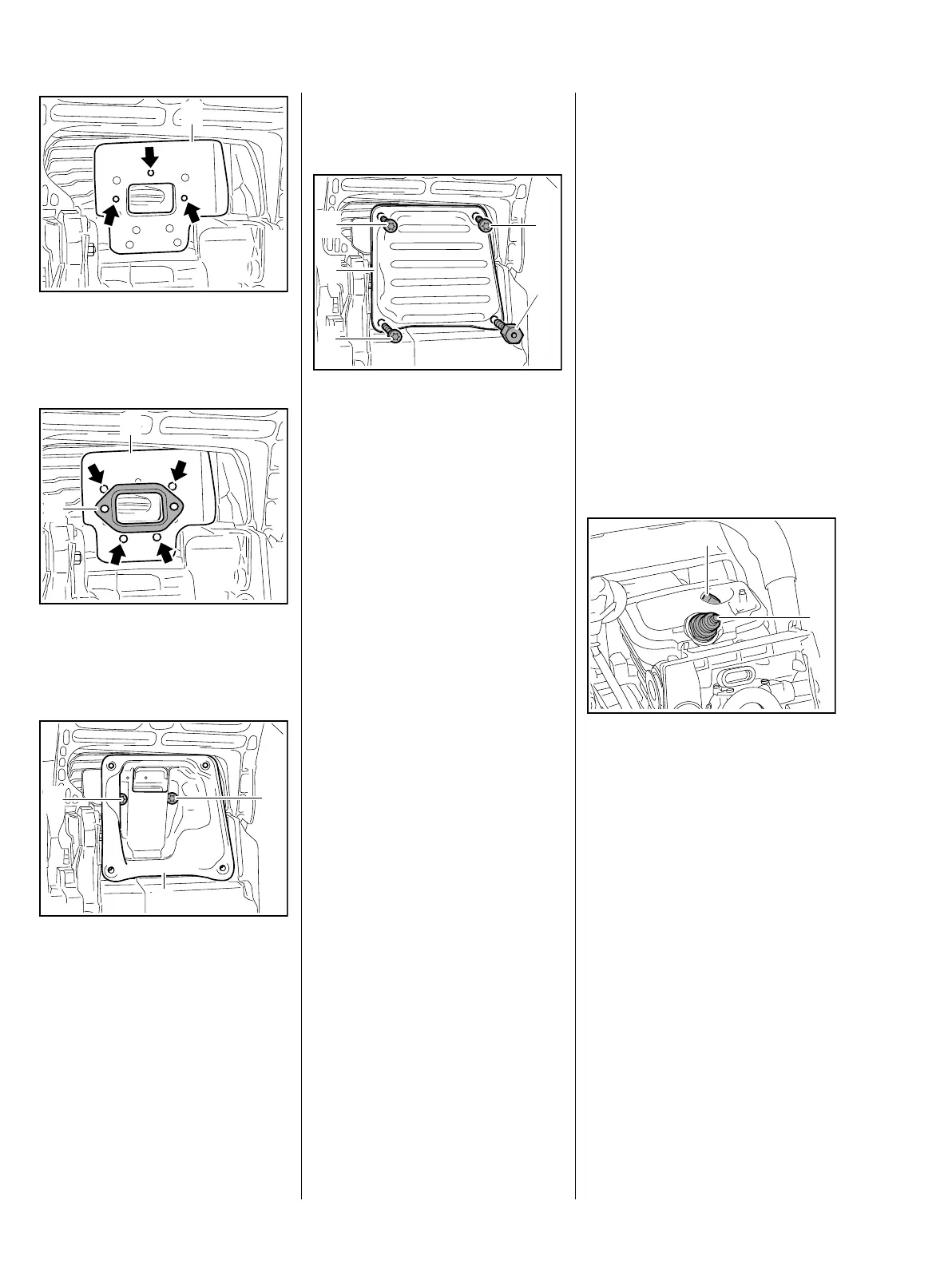

: Line up heat shield (1) with pegs

(arrows) on cylinder exhaust port

and place it in position.

: Line up the muffler gasket (1) on

the pegs (arrows) of the heat

shield (2) and place it in position.

: Carefully place the muffler (1) in

position.

: Coat screws (2) with

threadlocking adhesive, b 15

: Check the position of the heat

shield and gasket and fit the

screws (2).

3443RA014 TG

1

1

3443RA015 TG

2

3443RA016 TG

2

2

1

: Insert and tighten down the

screws (2) firmly.

– Fit a new gasket.

Special screw (4) is fitted only on

the rescue saw. Screw (3) is used at

the bottom left and right on all other

models and coated with

threadlocking adhesive.

: Coat screws (2 and 3) and

special screw (4) with

threadlocking adhesive, b 15

: Fit top casing (1), insert the

screws (2 and 3), screw (4) and

tighten them down firmly.

– On rescue saw, fit the guard

plate.

6.2 Leakage Test

Defective oil seals and gaskets or

cracks in castings are the usual

causes of leaks. Such faults allow

supplementary air to enter the

engine and upset the fuel-air

mixture.

This makes adjustment of the

prescribed idle speed difficult, if not

impossible.

1

2

3443RA019 TG

3

2

4

Moreover, the transition from idle

speed to part or full throttle is not

smooth.

Oil seals tend to fail when subjected

to a vacuum. Therefore, always

perform the vacuum test first and

then the pressure test.

The engine can be checked

thoroughly for leaks with the pump

0000 850 1300.

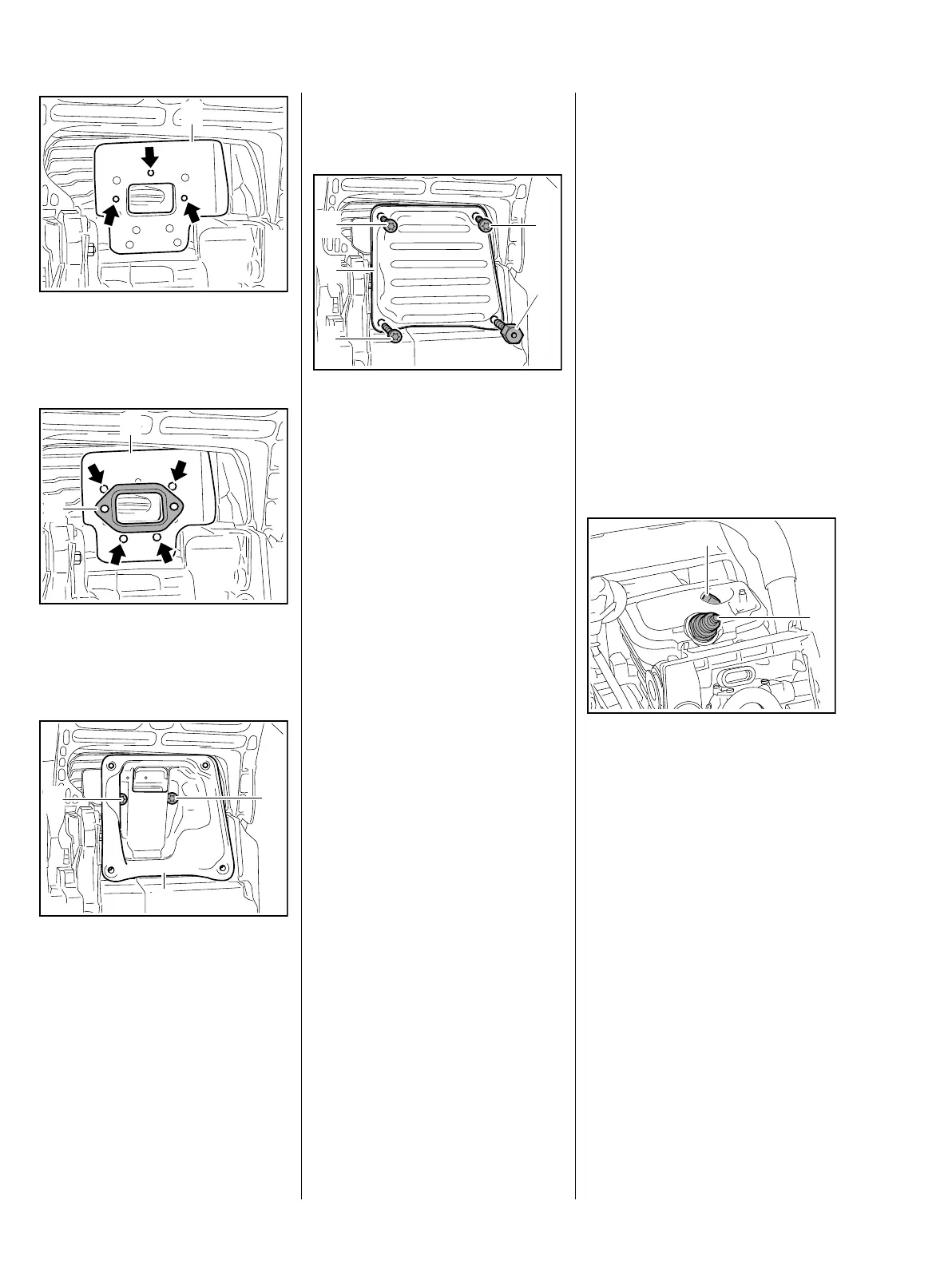

6.2.1 Preparations

– Remove the filter cover and air

baffle.

– Remove the shroud, b 6.4

– Pull off the boot and unscrew the

spark plug.

– Set the piston to top dead center.

This can be checked through the

spark plug hole.

– Remove the decompression

valve, b 6.9

: Fit the plug (1) 1122 025 2200

and tighten it down firmly.

: Fit the spark plug (2) and tighten

it down firmly.

– Remove the top casing and

loosen the muffler screws, b 6.1

3443RA062 TG

1

2

Loading...

Loading...