89MS 461, MS 461-R

Pressure test

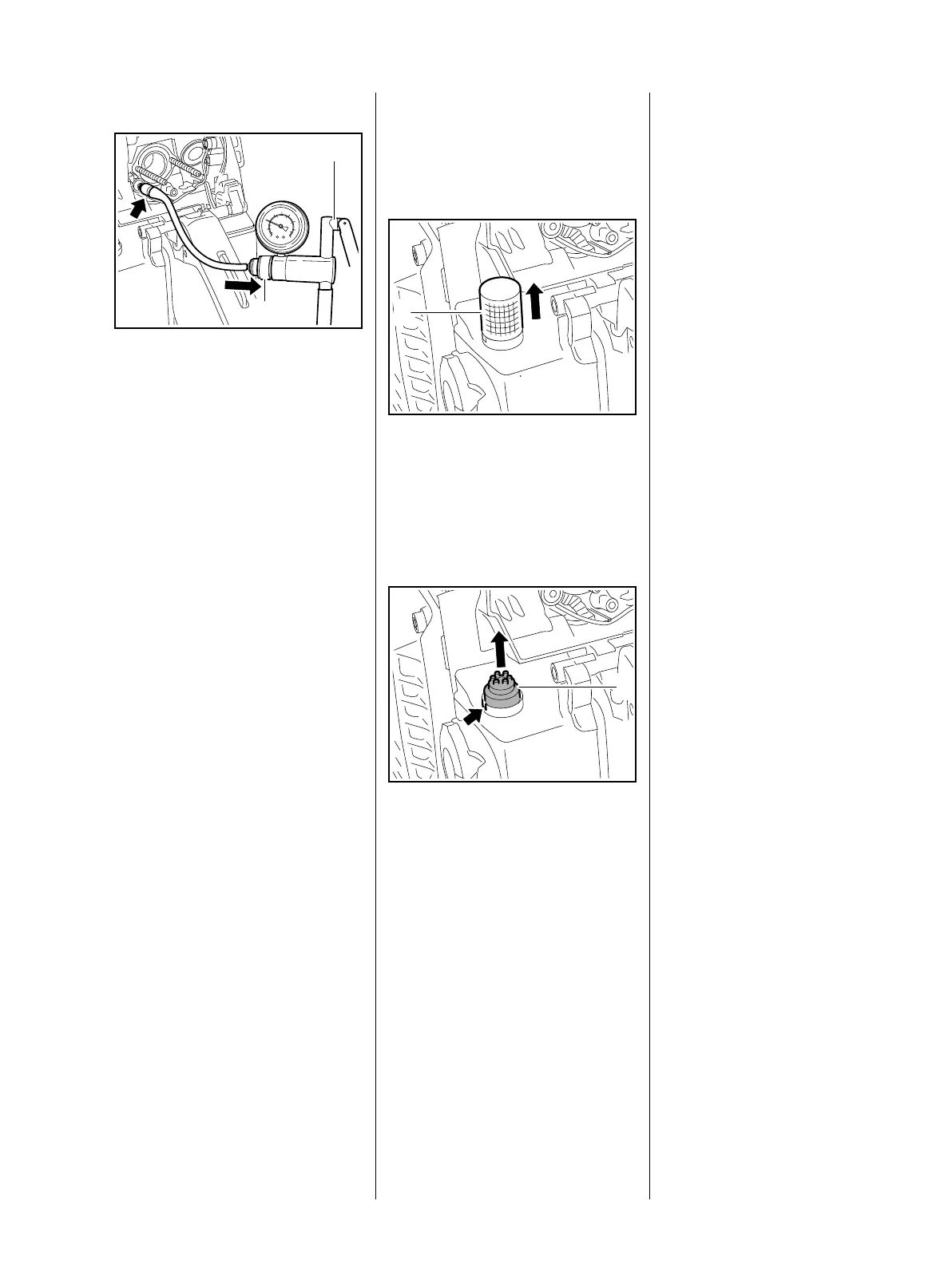

: Push the ring (1) to the right and

connect the pump (2)

0000 850 1300 to the nipple

(arrow) – pressurize the fuel tank.

– Operate the pump until the

pressure gauge indicates a

pressure of 0.5 bar. If this

pressure remains constant for at

least 20 seconds, the tank,

including the tank vent, is airtight.

If the pressure drops, the leak

must be located and the faulty

part replaced.

– Reassemble in the reverse

sequence.

2

1

3443RA442 TG

12.8.2 Removing and Installing

– Remove the air filter cover,

b 12.1

An optional fine dust filter is

recommended in work areas with a

high level of fine dust.

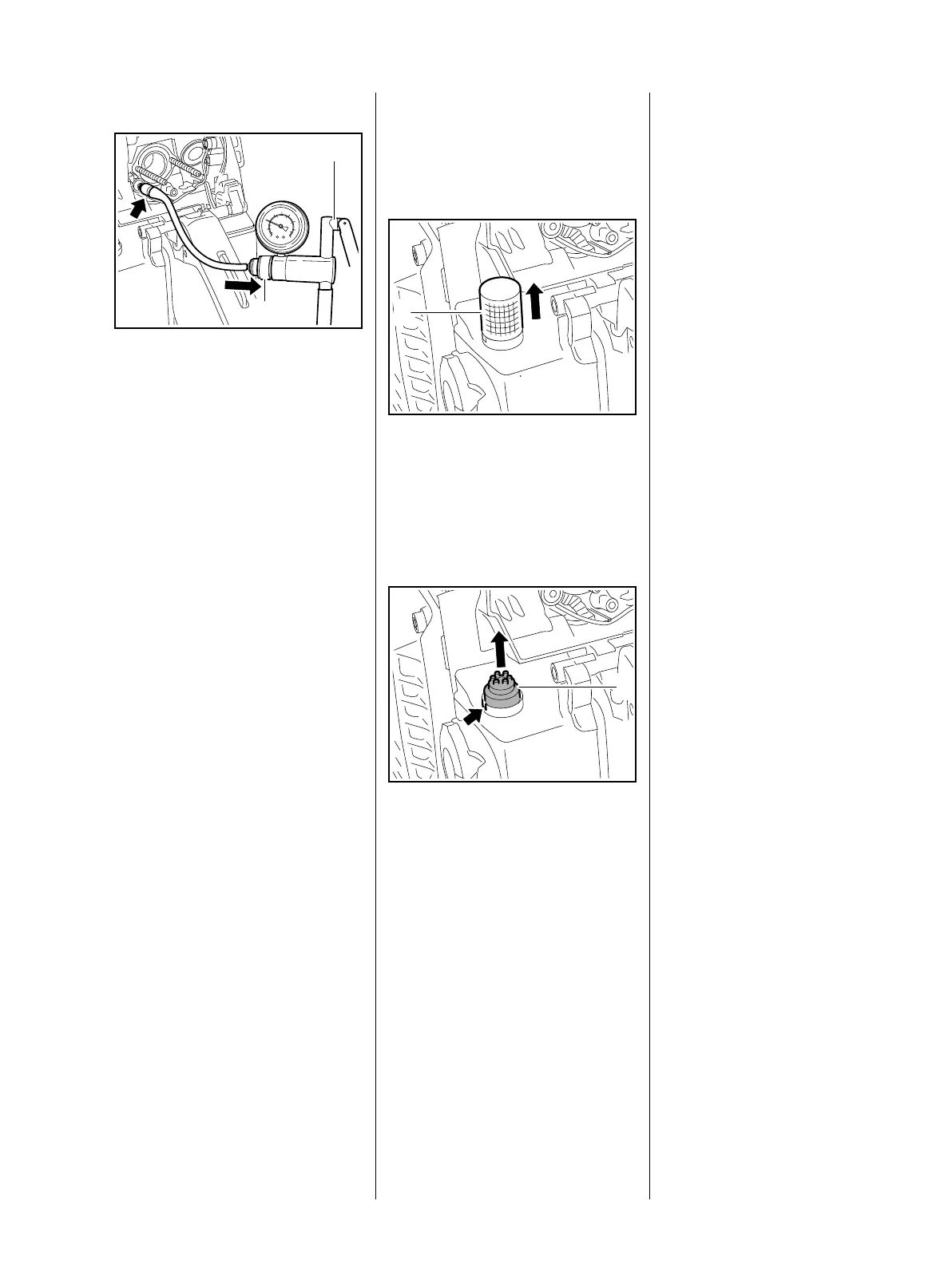

: Pull off the fine dust filter (1) (if

fitted).

: Pry the tank vent (1) out of its

seat using the rib (arrow) for

leverage – always install a new

tank vent.

Installing

– Coat sealing ring of new tank

vent with STIHL press fluid,

b 15

– Push home the tank vent by hand

until it snaps into position.

– Reassemble all other parts in the

reverse sequence.

3443RA443 TG

1

1

3443RA444 TG

12.9 Fuel Intake

12.9.1 Pickup Body

Impurities gradually clog the fine

pores of the filter. This restricts the

passage of fuel and results in fuel

starvation.

In the event of problems with the

fuel supply system, always check

the fuel tank and the pickup body

first.

– Troubleshooting, b 3.6 or

b 3.7

Clean the fuel tank if necessary.

– Open the tank cap and drain the

tank.

– Pour a small amount of clean

gasoline into the tank. Close the

tank and shake the saw

vigorously.

– Open the tank again and drain it.

– Dispose of fuel properly in

accordance with environmental

requirements, b 1

– Open the tank cap.

Loading...

Loading...