74 MS 461, MS 461-R

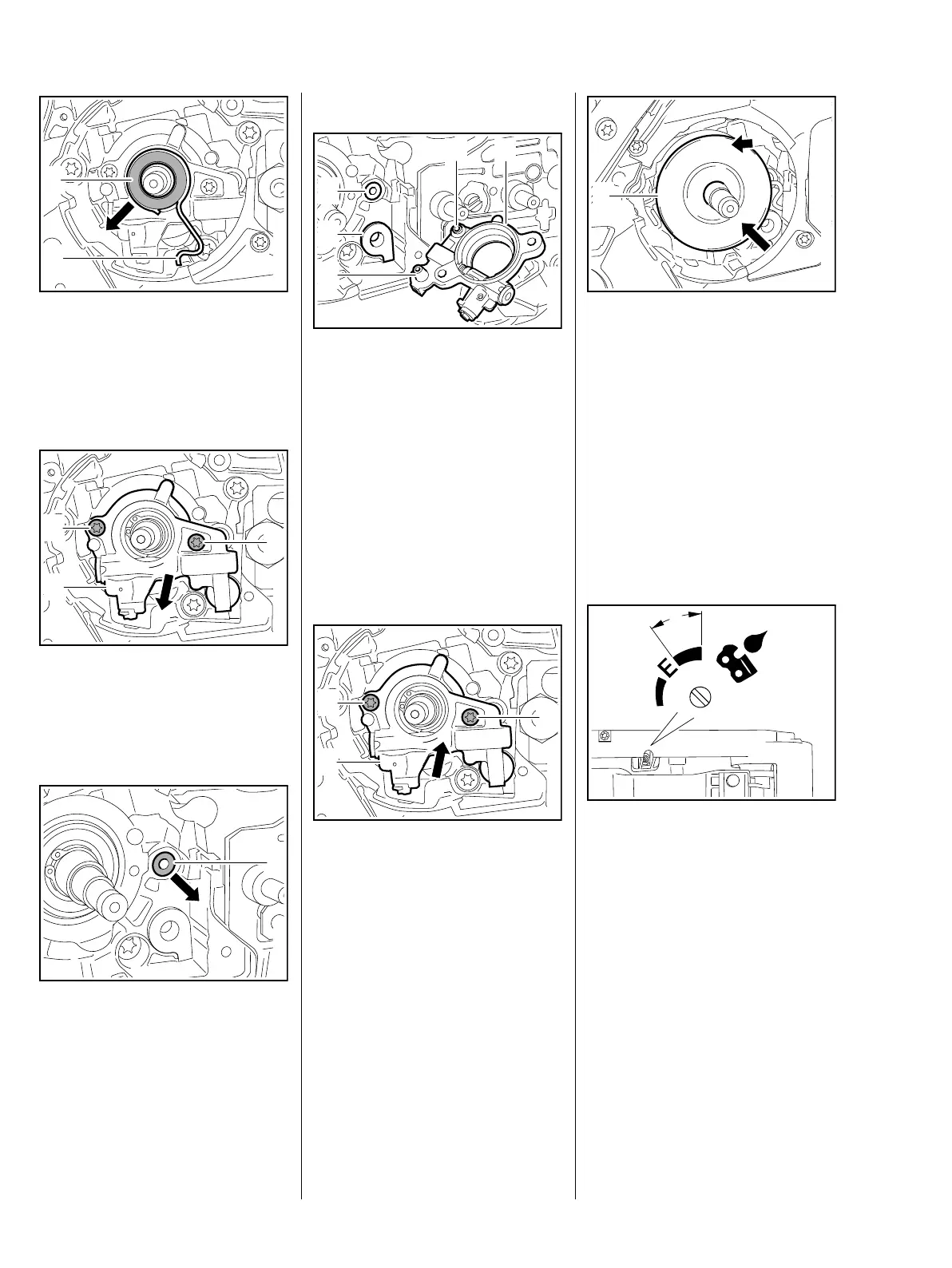

: Pull the worm (1) with drive

spring (2) out of the oil pump.

– Check the spring and worm and

replace if necessary.

: Take out the screws (1).

: Pull off the oil pump (2), check

and replace if necessary.

: Install a new sealing ring (1).

Always use a new sealing ring.

1

3443RA148 TG

2

3443RA490 TG

1

2

1

1

3443RA421 TG

Installing

– Lubricate the pump piston with

STIHL multipurpose grease,

b 15

–

: Line up the oil pump (1) so that

the stub (2) engages the oil

suction hose (3) and face (4) with

hole locates against the sealing

ring (5).

– Coat stub and sealing ring with

STIHL press fluid, b 15

: Push oil pump (1) into position.

: Fit the screws (2)

and tighten them down firmly.

– Push the worm fully home.

3443RA422 TG

1

4

3

5

2

2

1

2

3443RA423 TG

: Push the washer (1) into position.

– The word "TOP" (arrow) must

face outwards.

– Reassemble all other parts in the

reverse sequence.

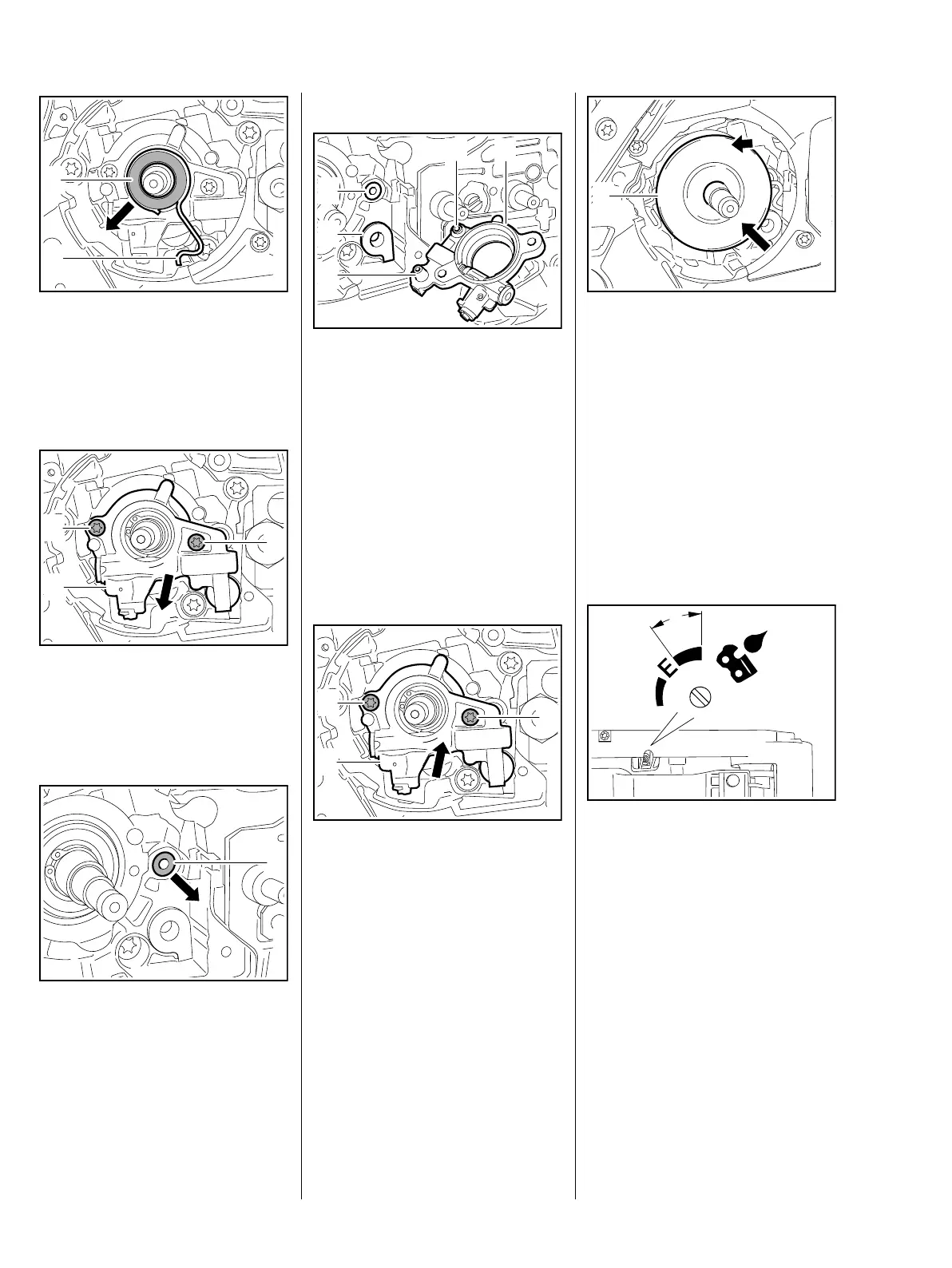

11.3.1 Adjusting Uprated Oil

Pumps

See owner's manual for most

suitable settings for different uses.

When oil pumps with an increased

oil flow rate are set within range "a",

note that the oil tank runs dry before

the fuel tank and the saw chain will

then have insufficient lubrication.

Therefore, if pump is set to range

"a", fill fuel tank to half full mark only

or refill oil tank when fuel tank is half

empty.

TOP

1

3443RA424 TG

a

3443RA425 TG

Loading...

Loading...