Maintenance

8 — 2 07_0075_0802GB

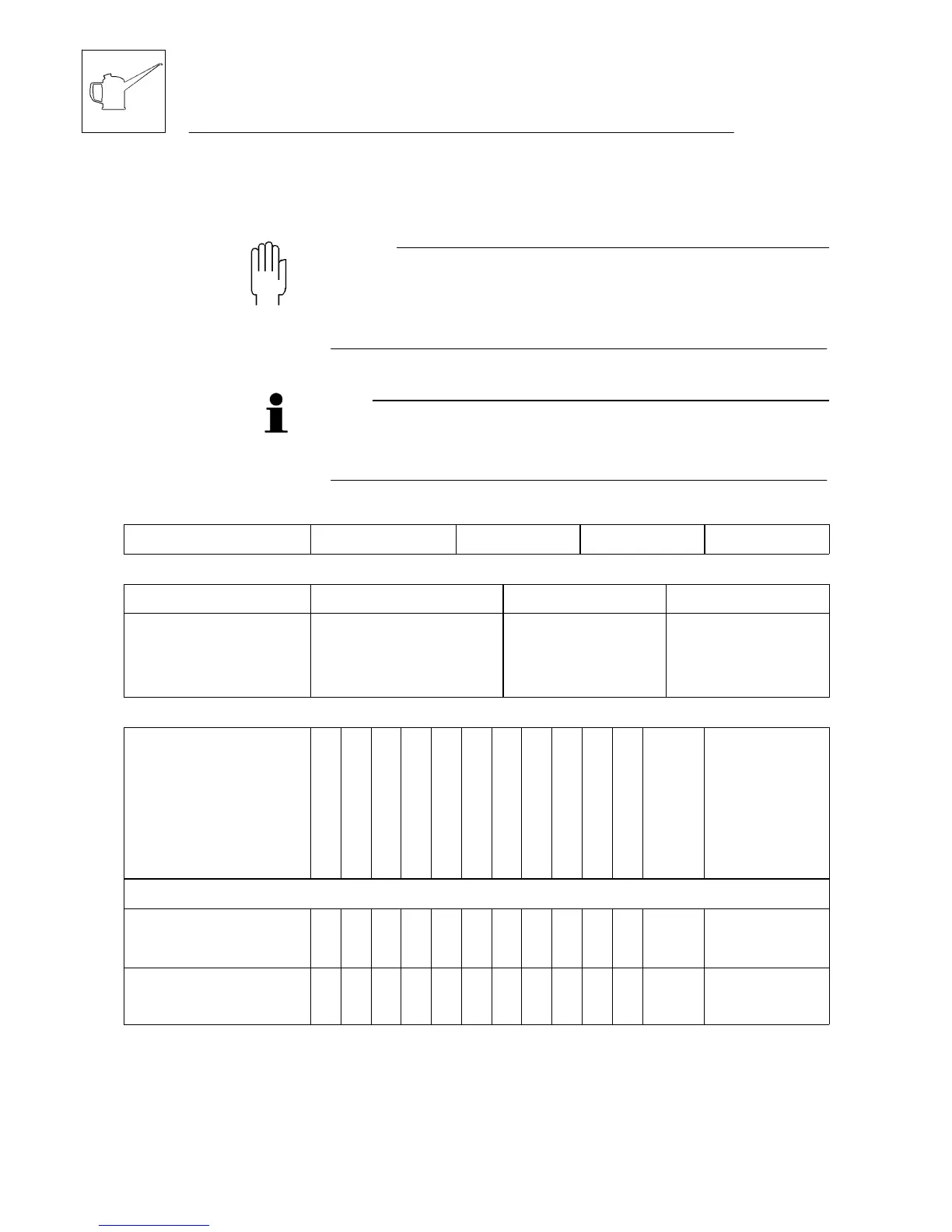

The following table shows the intervals for the various maintenance

t

a

sks.

C

aution

Inspection and maintenance personnel must have authorisation and

the necessary technical qualification. They must have completed

training relevant to working with the equipment on the machine and

be conversant with the content of the operating instructions.

Note

Use only original spare parts.

Maschinenbau Rudolf GmbH accepts no liability for damage caused

as a result of using non-original spare parts.

Criteria

Check

n

Adjust

J

Replace

⇔

Clean

Z

Reference

Section Service

MC

Description

Section contains a more de-

tailed description

Maintenance work that

should be performed by

a service technician

authorised by

Maschinenbau Rudolf

Maintenance chart

Action

daily

once after 50 h

every 50 h

every 100 h

every 150 h

every 300 h

every 400 h

every 500 h

every 1000 h

annually

every 2 years

other intervals

Reference

General machine

Check that the fastening

bolts are seated correctly

n

after the

first 10 h

Section:

General tightening

torques

Visual inspection: defects

and leaks, rectify defects,

seal leaks

n

8.1 Maintenance intervals

Loading...

Loading...