Assembly & Installation

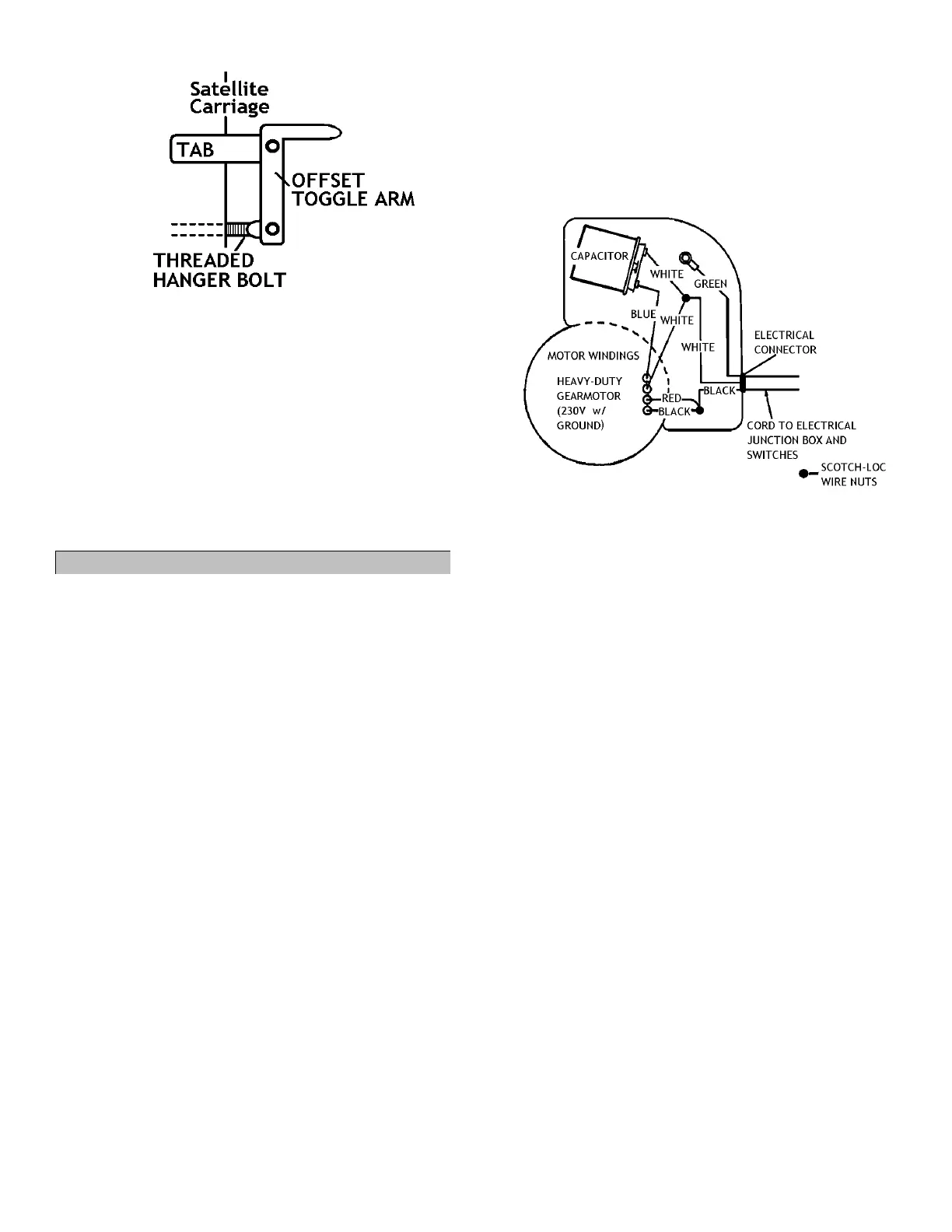

Figure 26 - Satellite-Carriage End of Reversing Mechanism

53 Bolt threaded hanger bolt (now screwed into

reversing rod) to toggle arm using a 5/16”

shoulder bolt and 1/4” locking nut. Ensure

reversing mechanism is still in centered

position; toggle arm should still be parallel to

edge of carriage. Figure 26.

54 Tighten all 3 shoulder bolts using a 5/32” hex

(Allen) wrench and a 7/16” wrench.

55 Ensure reversing mechanism can move freely by

shifting it from one locked position to the other.

IX. Wiring Gearmotor on Center Hanger

For part numbers and descriptions of parts

referenced in this section, see parts assembly

manual, page 53.

56 Run black 18 ga. 3-wire cord from primary

carriage junction box underneath crosstube and

tie bar and tie-strap cord to cord support strap.

57 Run cord along cord hanger and down side of

center hanger, securing cord using provided

black zip ties.

58 Remove curved cover with Sukup logo on front

of gearmotor junction box using 5/16” wrench.

Save 1/4" screws.

59 Insert 3/8” electrical connector from hardware

sack into hole on side of gearmotor junction

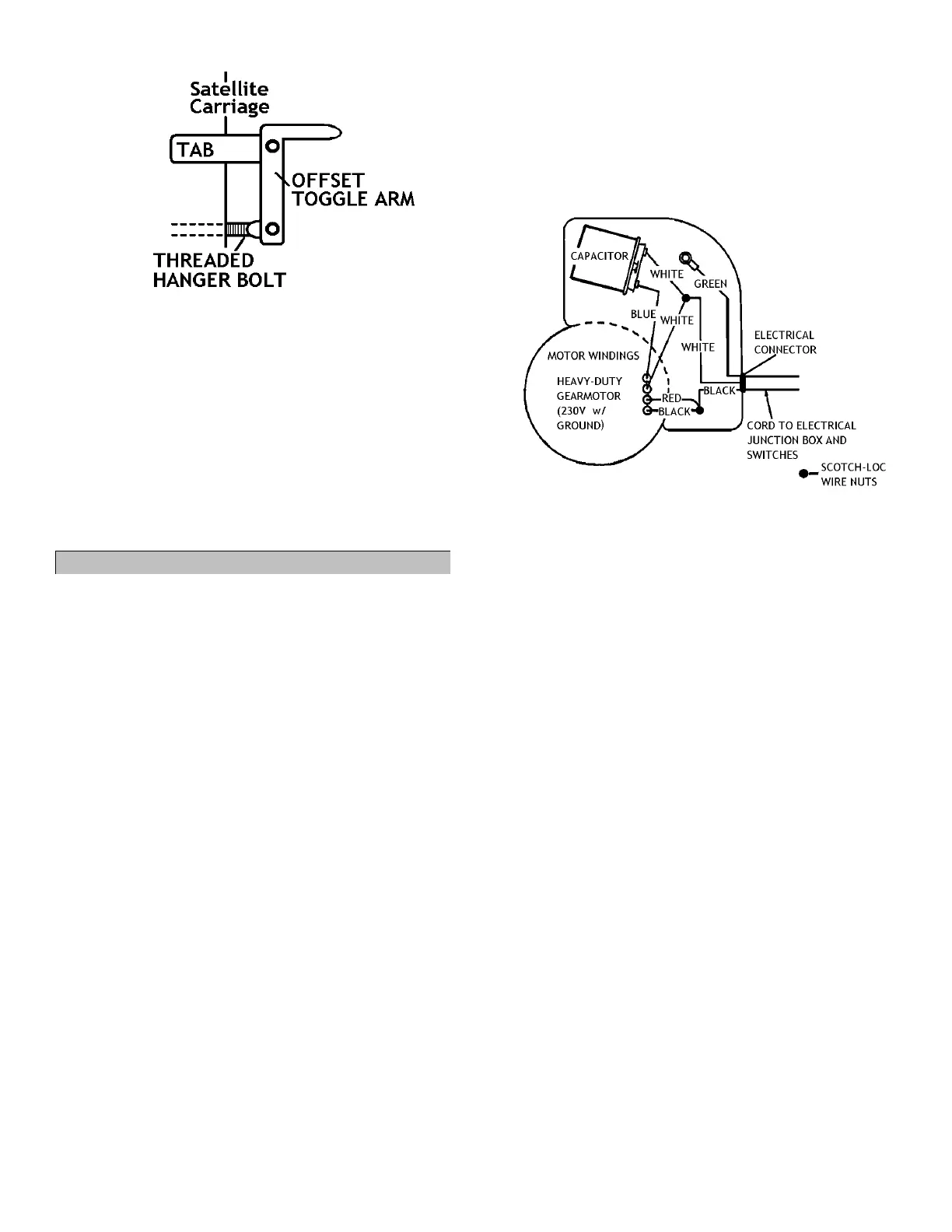

box. Figure 27.

60 Tighten metal fastening ring inside of box.

61 Thread 3-wire cord through electrical connector,

providing a drip loop in cord by motor. Secure 3-

wire cord by lightly tightening connector screws

using screwdriver.

61.1 Note: At this point, there will be 4 wires

from gearmotor and 3 wires from 3-wire

cord inside gearmotor junction box.

62 Connect loose, short white wire with female

spade (located in plastic sack on junction box

wire) to terminal of capacitor that is included

inside gearmotor junction box. Figure 27.

62.1 Note: Sack with white wire should come

attached to carriage junction box and also

includes yellow wire nuts.

62.2 Note: In steps 62-66, ensure wires and wire

nuts are connected tightly so they do not

vibrate out of place during use of machine.

Figure 27 - Gearmotor Junction Box Wiring Diagram

63 Connect blue wire with female spade from

gearmotor to terminal on opposite side of

capacitor. Figure 27.

64 Strip back 1/2” of rubber insulation on white,

red, and black wires from gearmotor using wire

stripper.

65 Using yellow wire nut from attached part sack,

connect:

White wire from 3-wire cord

White wire from gearmotor

White wire from step 62. Figure 27.

66 Using yellow wire nut from attached part sack,

connect:

Black wire from 3-wire cord

Black wire from gearmotor

Red wire from gearmotor. Figure 27.

67 Secure green ground wire from 3-wire cord

under the ground screw inside junction box.

67.1 Note: All wires should now be connected

somewhere.

68 Place capacitor and all wires back into

gearmotor junction box.

69 Replace cover from step 58 on gearmotor using

reserved 1/4” screws and 5/16” wrench.

69.1 Note: Ensure wires are not pinched

between gearmotor junction box and box

cover before tightening cover down.

Loading...

Loading...