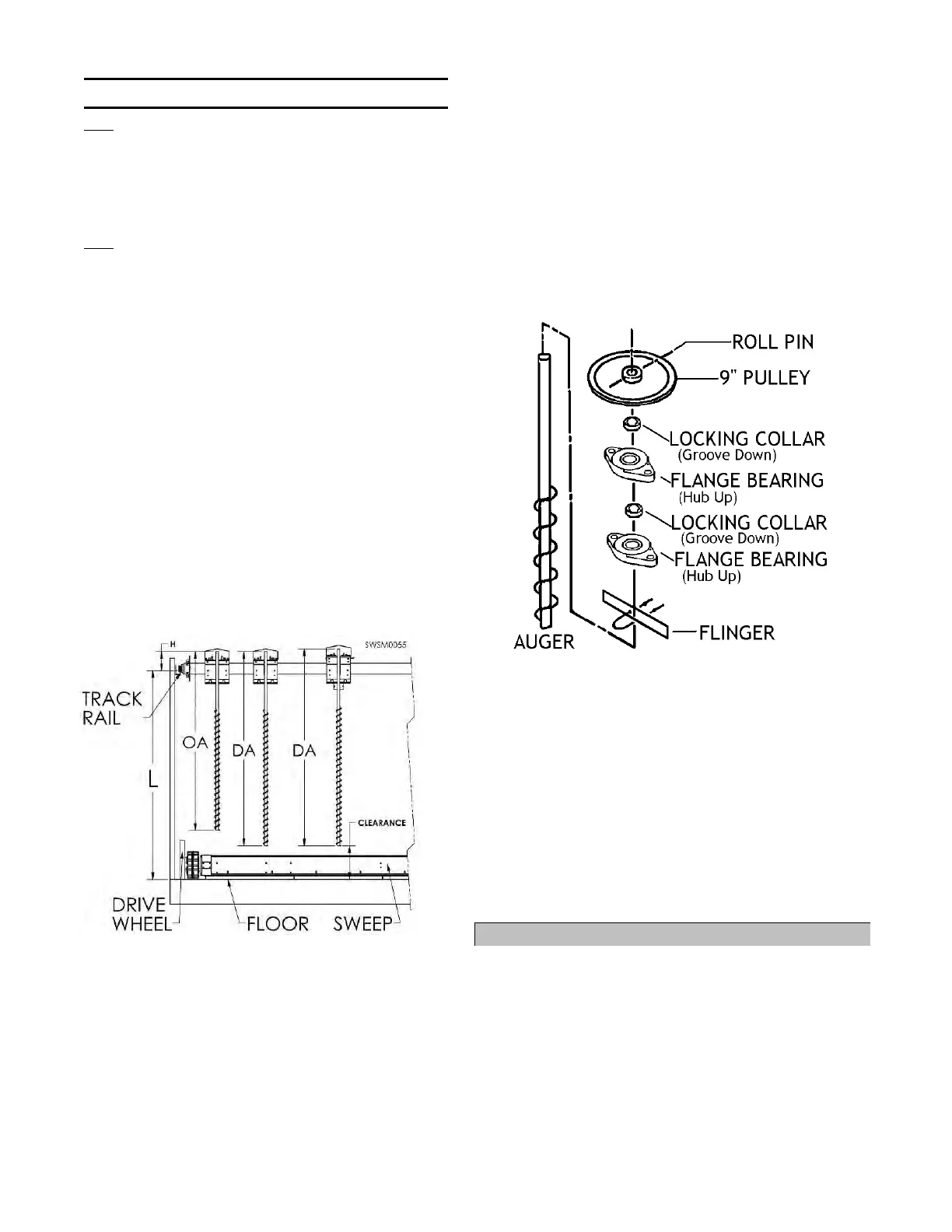

Assembly & Installation

DOWN AUGER LENGTH EXAMPLES

EX1: An existing 30' bin will have a FASTIR Triple

installed. “L” is measured at 200". There is no

sweep and a 4" clearance between the floor

and the auger will be used.

DA = 200 + 7.5 - 4

DA = 203.5"

EX2: A new Sukup 6-ring, 42' farm bin (265" eve

height) will have a FASTIR Plus Triple

installed during bin assembly. An 8" Sukup

powered sweep will be installed on a floor with

13.25" floor supports.

L = (265" eave height) - (13.5" for floor) - (7.5" for

top of sheet to rail)

L = 265 - 13.5 - 7.5

L = 244"

DA = (244" for L) + (8.0" for H) - (10" for sweep) -

(4" for clearance)

DA = 244 + 8.0 - 10 - 4

DA + 238"

Because a Sukup powered sweep will be installed,

the stationary carriage will need a shorter auger.

OA = (244" for L) + (8.0" for H) - (17" for sweep

wheel) - (4" for clearance)

OA = 244 + 8 - 17 - 4

OA = 231"

Figure 36 - Down Auger Preparation

94 Mark appropriate position on auger for cut.

95 Weld or braze flighting slightly above point

of cut to prevent unraveling.

96 Cut down augers to length.

96.1 Note: Down augers should always be cut

from bottom.

96.2 Note: In some cases, down augers may be

cut after installation on machine.

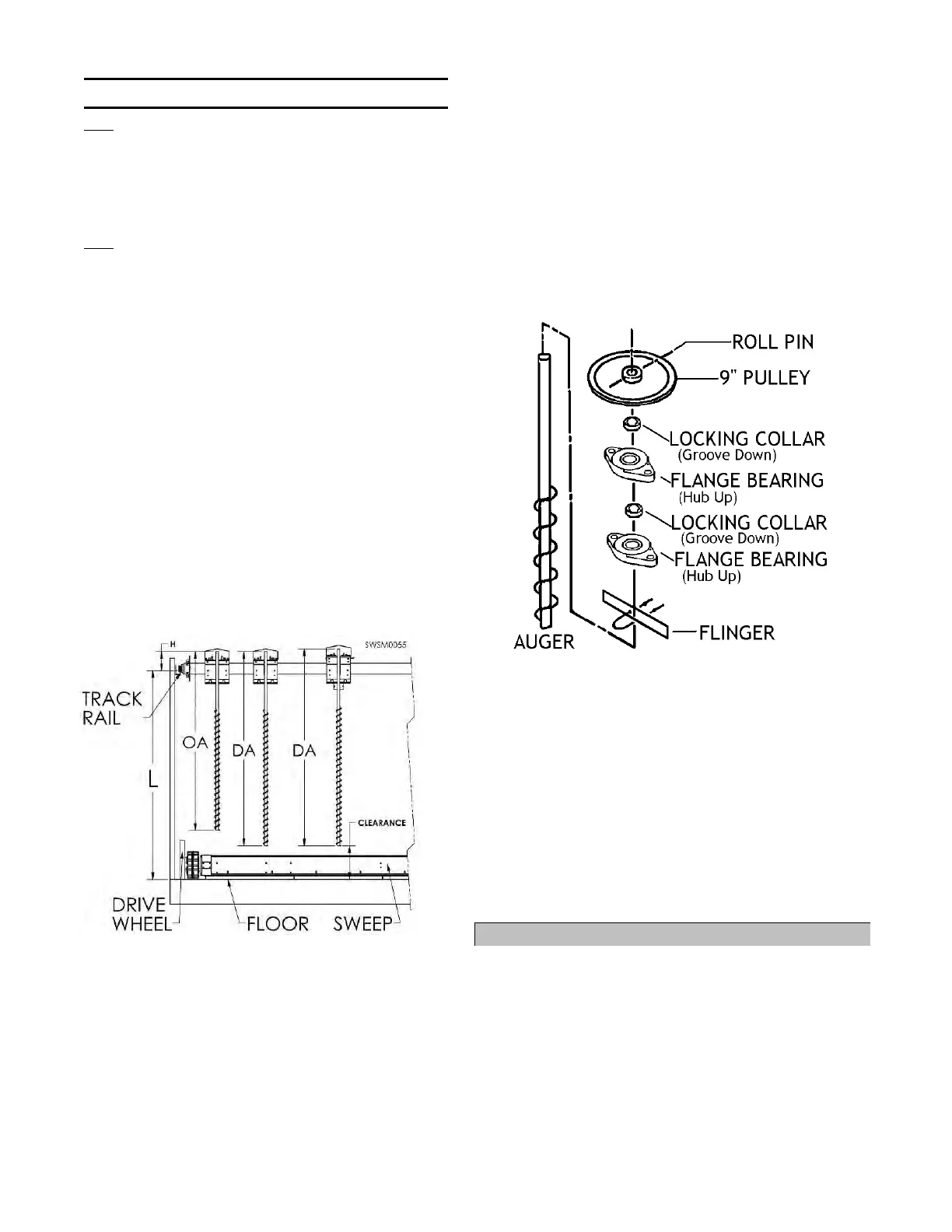

97 Bolt flinger to auger just above auger flighting

using 5/16” x 1-3/4” U-Bolt and 5/16” nuts and

tighten using 1/2” wrench. Figure 37.

98 Slide the following items over top of each auger

shaft in the order below:

Flange bearing (hub up)

Locking collar for bearing (groove down)

Flange bearing (hub up)

Locking collar for bearing (groove down)

9” pulley (hub up). Figure 37.

98.1 Note: If parts will not slide smoothly over

shaft, use emery cloth or file to clean shaft.

Figure 37 - Down Auger Assembly

99 Attach 9” pulley to top of auger shaft by

inserting 5/16” rollpin in hole provided on shaft.

Figure 37.

100 Slide top locking collar and top flange bearing

up against pulley.

101 Position a punch in unused hole on locking

collar and lightly tap with hammer in direction

of shaft rotation to lock flange bearing in place.

101.1 Note: Do not overtighten collar –

bearing race will crack.

102 Tighten set screw on top locking collar using

hex (Allen) wrench.

XVI. Installing Down Augers

For part numbers and descriptions of parts

referenced in this section, see parts assembly

manual, page 53.

103 Slide auger up through slot in carriage so top

bearing rests on two pre-installed 7/16” x 1-1/2”

bolts, which point up through top of carriage plate

and are secured with push nuts. Figure 38.

104 Add 7/16” lockwashers and nuts to pre-

installed bolts to bolt top bearing to carriage.

Tighten using 11/16” wrench. Figure 38.

Loading...

Loading...