38

Sunstone Welders User Manual: CDDP-A

CDDP-A Data Tables

WELDER DATA SPECIFICATIONS

Cabling between welder and weld head is important in determining peak weld current and adjusting

weld pulse timing. Table 1 indicates peak currents that can be expected with 3 to 4 foot sections of

these cables. Typically, hand pieces will use 4 to 8 AWG wire while Weld Heads will be hooked up

with 2/0 or 4 AWG wire.

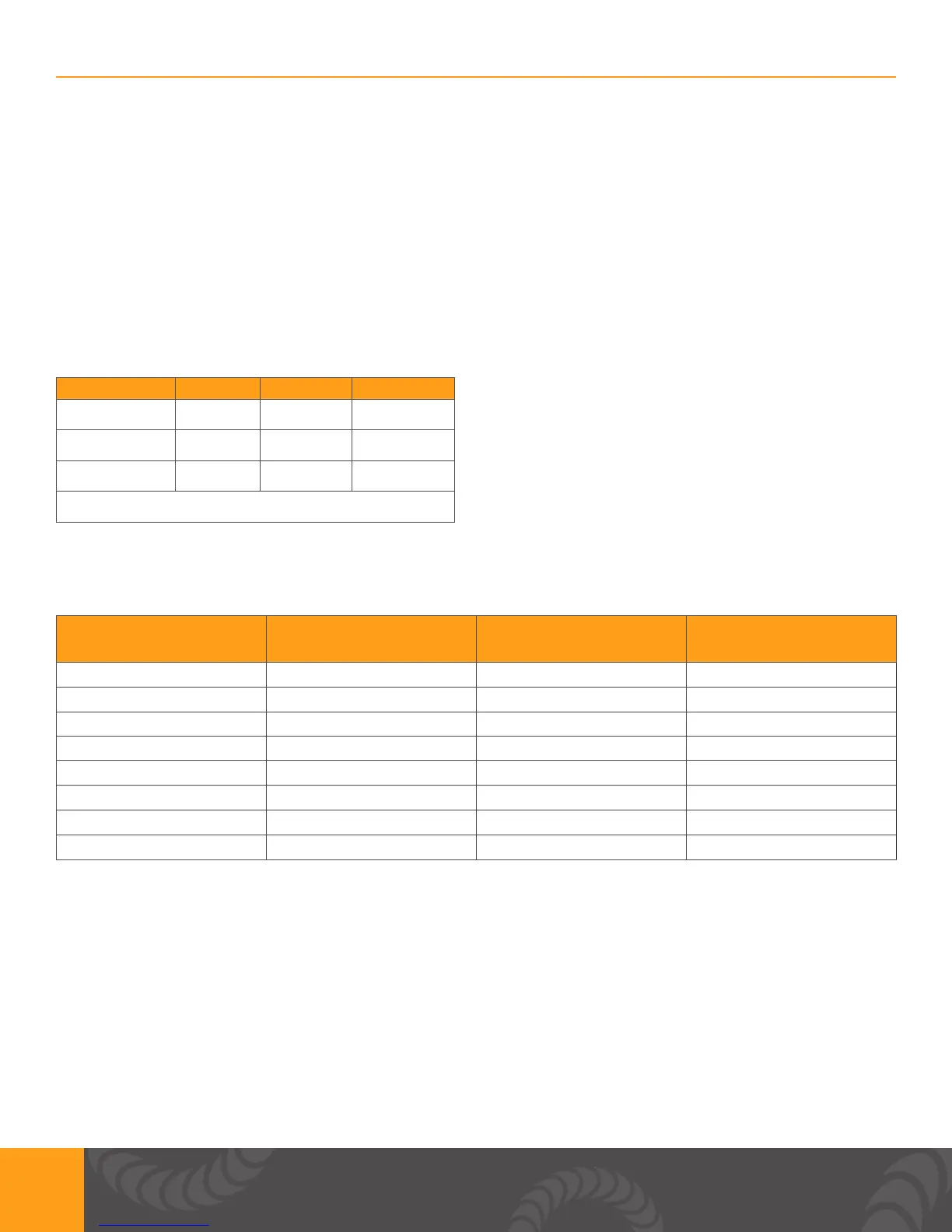

TABLE 1: Peak weld current shown by model number and external cabling gauge number (AWG).

Four and eight AWG cabling is typically seen when using hand held attachments.

CD200DP-A CD400DP-A CD600DP-A

1 AWG4 Ft 6583 7625 8080

4 AWG 6Ft 5448 6310 6690

8 AWG 6 Ft 3038 3520 3730

*Minimum Load = 1mOhm, using a smaller load may damage the welder.

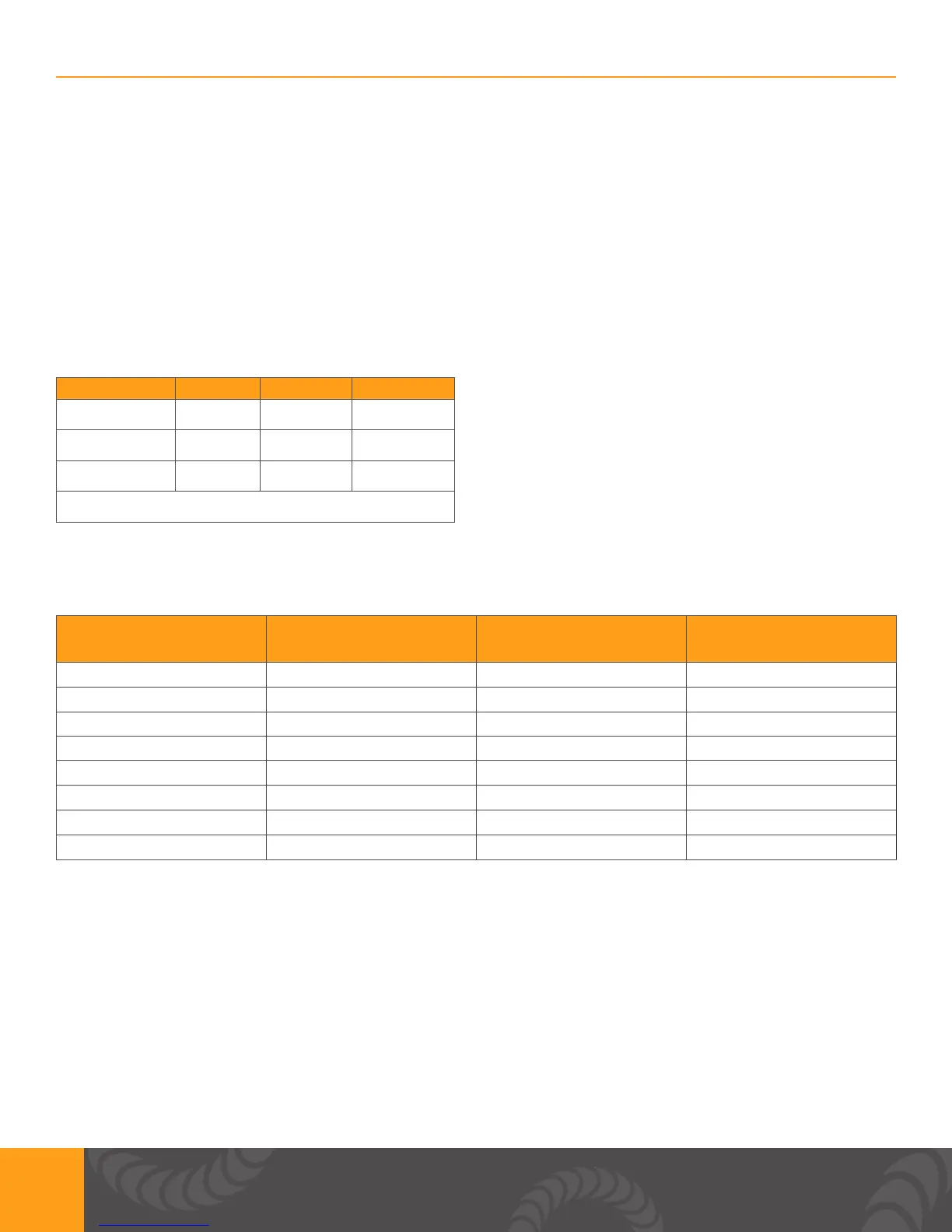

TABLE 2: Weld speed in welds per minute by dual pulse model number at maximum energy.

% of Total Weld Energy

(Pulse Width at 100%)

Rep Rate

CD200DP-A

Welds/Min (pulse energy)

Rep Rate

CD400DP-A

Welds/Min (pulse energy)

Rep Rate

CD600DP-A

Welds/Min (pulse energy)

0.10% both pulses enabled 650 (0.2ws) 600 (0.4ws) 530 (0.6ws)

0.10% 550 (0.2ws) 530 (0.4ws) 500 (0.6ws)

1% 450 (2ws) 290 (4ws) 240 (6ws)

5% 250 (10ws) 160 (20ws) 130 (30ws)

10% 190 (20ws) 120 (40ws) 90 (60ws)

25% 130 (50ws) 70 (100ws) 60 (150ws)

50% 90 (100ws) 50 (200ws) 40 (300ws)

100% 60 (200ws) 30 (400ws) 30 (600ws)

Loading...

Loading...