Questions? Call or Text +1-801-658-0015 • 21

e Micro Welder Experts

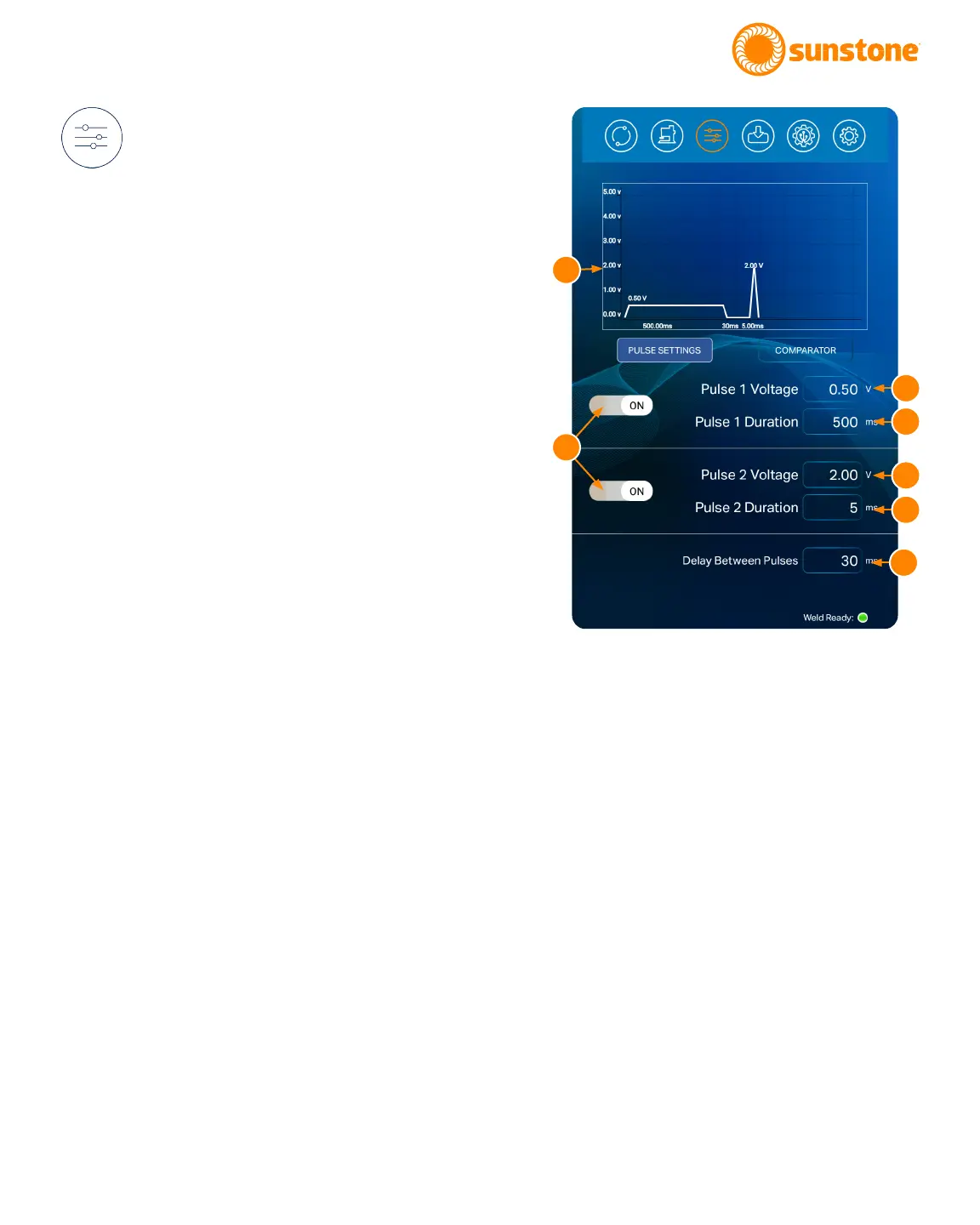

Weld Settings Screen

Operation

The Weld Settings Screen is used to set the desired

voltage and duration of the weld discharge. The Pico

can be congured to release two independently set

pulses of weld energy with customizable pre-weld delay

and delay between pulses.

Pulse settings dictate the amount of energy that will

be released during each weld. As voltage and length

increase, weld heat will increase.

A graph (A) at the top of the Weld Control Screen dis-

plays a visual representation of the expected waveform

based on the weld settings and parameters you choose

here. Weld voltage is displayed on the Y axis and weld

discharge length (time) is displayed on the X axis.

A total of two weld pulses can be enabled/disabled. Us-

ing multiple pulses can increase weld quality. With both

pulses enabled, the Pico will discharge two separate

times with each weld trigger/initiation. The rst pulse is

useful to remove surface inconsistencies and contami-

nants which helps to displace oils, break through oxide

layers, and seat the welding electrodes. The second

pulse is used to fuse the metals.

To set pulse parameters, rst toggle the button (B) to

ON to enable the pulse, or OFF to disable the pulse for

Pulse 1 or Pulse 2. If both pulses are disabled, no weld

will occur and an alert will display if a weld is triggered.

The voltage of each pulse can be adjusted from 0.1 V to

5 V. To adjust voltage, touch the Voltage box (C) of the

desired pulse. A pop-up box will appear. Use the slider

bar or the number pad to set the displacement limit; or

incrementally adjust the value using the arrow buttons.

Press the Close Button to enter the limit.

Figure 21.1. The Weld Settings Screen is used to set the

desired voltage and duration of the weld discharge. The

Pico can be congured to release two independently

set pulses of weld energy with customizable pre-weld

delay and delay between pulses. Press the Voltage and

Duration boxes to change values.

A

C

B

C

D

D

E

Loading...

Loading...