Questions? Call or Text +1-801-658-0015 • 5

e Micro Welder Experts

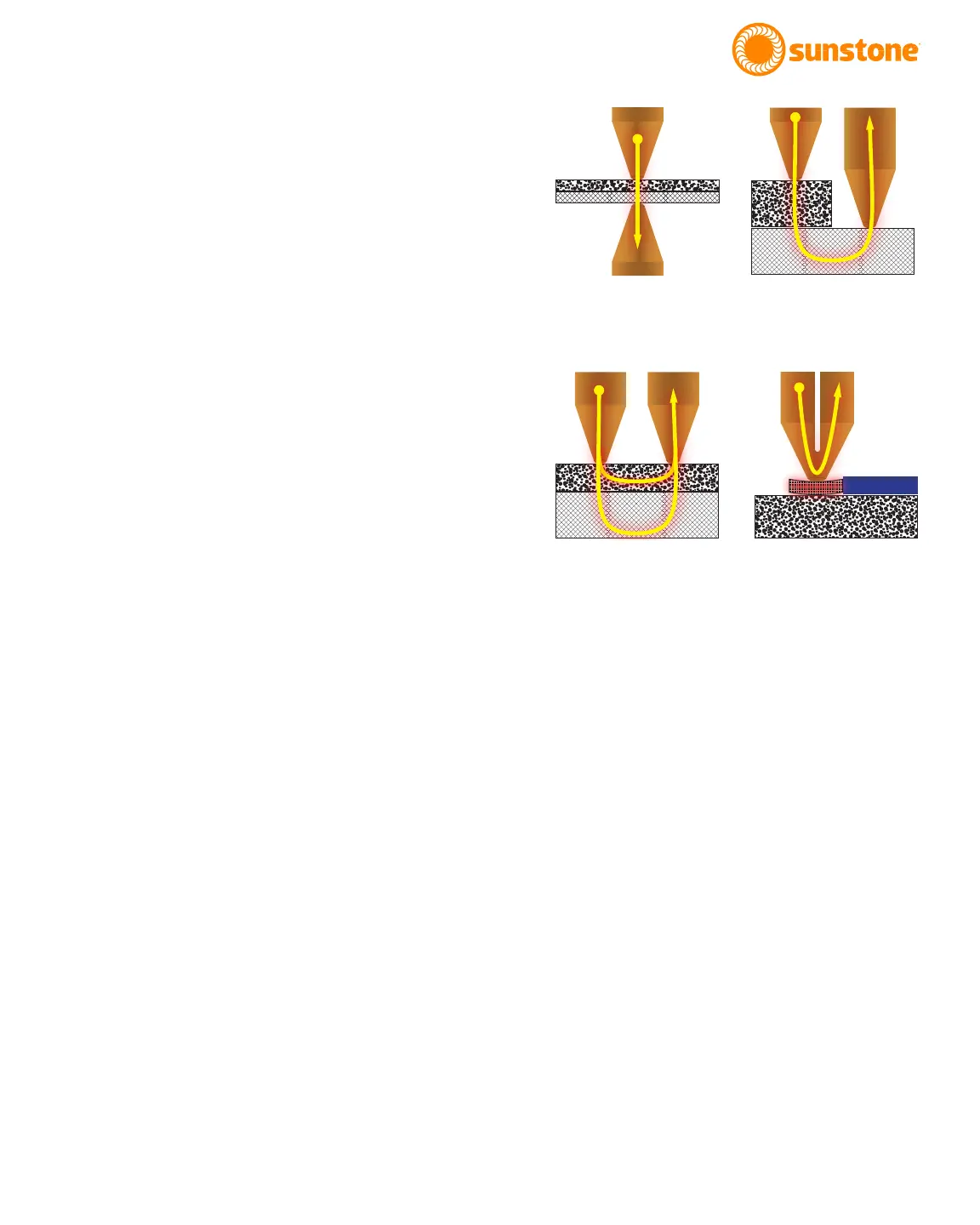

Direct weld (Opposed)

Current passes from one electrode through both

workpieces and out the opposing electrode. Typically

the easiest conguration to achieve good weld nuggets

and strength. See Figure 5.1.

Step (Adjustable Gap)

The electrode is placed on both materials, but from the

same side. A step or adjustable gap electrode congu-

ration can be challenging when maintain proper pres-

sure at each electrode due to possibly uneven surface.

See Figure 5.2.

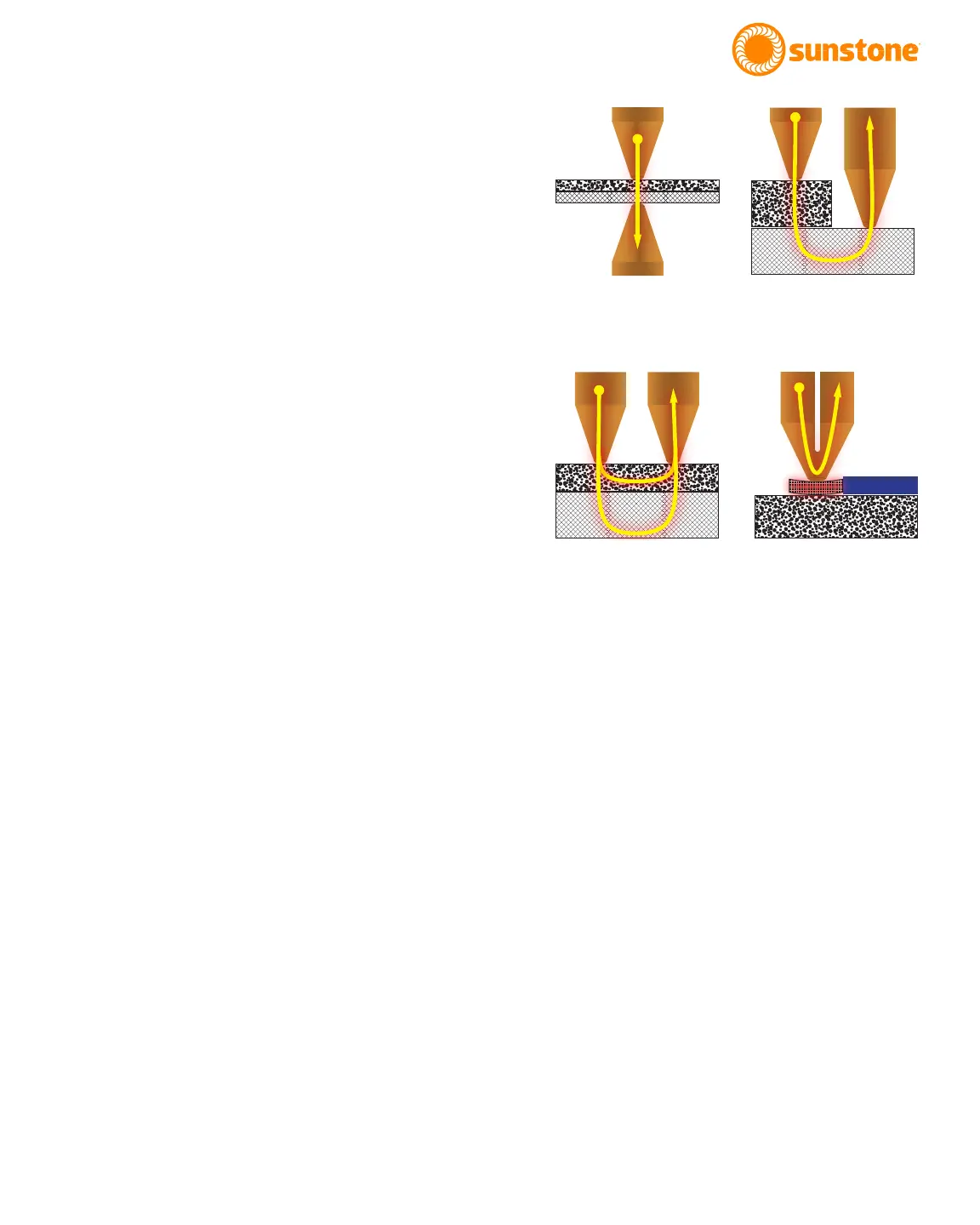

Series (Adjustable Gap/Fixed Gap)

The electrodes are placed on the surface material only.

Because the current is split between both materials,

sometimes this conguration requires more weld ener-

gy than a direct weld would. See Figure 5.3.

Thermocompression

In a thermocompression conguration, the current

does not pass through the materials being welded, but

rather the current passes through the electrode tip. A

thermocompression conguration is most useful for

coated surfaces like magnet wire. See Figure 5.4.

How to Maintain Repeatable Welds

Consistent weld results require a consistent and

repeatable process. A few suggestions for ensuring

repeatable welds include:

• Keep a weld logbook documenting the process

once a successful weld has been achieved. Try

to keep track of the following:

• Force applied

• Electrodes (tip size/shape, electrode

material, etc.)

Figure 5.1. Direct

(opposed) electrode

conguration.

Figure 5.2. Step

(adjustable gap) electrode

conguration.

Figure 5.3. Series

(adjustable gap/xed gap)

electrode conguration.

Figure 5.4. Thermocom-

pression electrode cong-

uration.

Loading...

Loading...