© Copyright Mission Critical Energy Inc, 2019 Version 1-2019

www.superwind.com

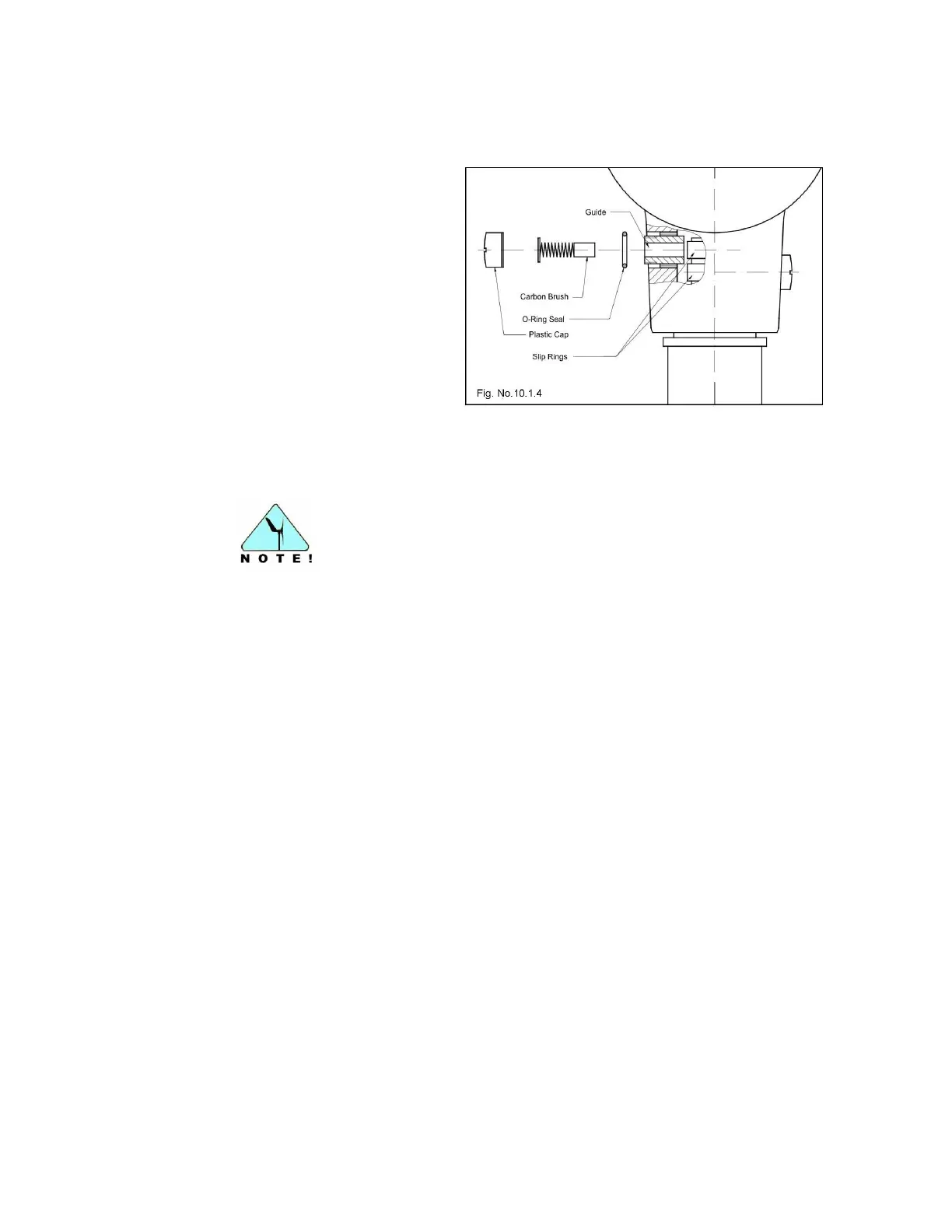

10.1.4 Slip rings

Electrical power is transmitted

from the yawing nacelle to the

stationary mast via slip rings.

The carbon brushes used to

accomplish this are designed to

last the life of the generator,

however periodic checks for

unusual wear or loss of contact

material is recommended.

Unscrew the two black

cylindrical screw caps (see fig.

10.1.4) and remove the carbon

brushes to inspect. Worn or

damaged carbon brushes must

be replaced. Carbon brushes should be replaced in pairs (replacement brushes are

sold in pairs and include new screw caps). Inspect the cap O-ring seals for damage

prior to reinstallation.

Use caution when unscrewing the two plastic screw caps. The

carbon brushes are spring loaded and can rapidly exit the unit,

resulting in loss of the brush assembly.

10.1.5 Corrosion protection

The generator housing and wind vane are constructed of a corrosion resistant, marine

grade aluminum alloy that is also powder coated for additional corrosion protection.

Inspect this powder coating and touch up any damaged areas noted with a suitable

lacquer paint.

All steel parts (e.g. ball bearings, shafts, axles and bolts) are stainless steel and need

no special corrosion protection.

10.1.6 Mast

Check the mast or support structure for damage, corrosion, loose hardware, etc.

Refer to the appropriate mast or support installation guides.

10.1.7 Electrical system

Electrical system inspections must be performed by qualified personnel. Before

performing any inspection, verify that all lines are safe and that the wind generator is

secured and cannot start unexpectedly.

Check all electrical connections, making sure that they are tight and free from

corrosion. Pay particular attention to battery terminals, which are especially prone to

corrosion. Clean all terminals of corrosion and coat with a suitable battery terminal

grease to prevent future corrosion.

Loading...

Loading...