ENGINE 3-25

CYLINDER HEAD

VALVE AND VALVE SPRING DISASSEMBLY

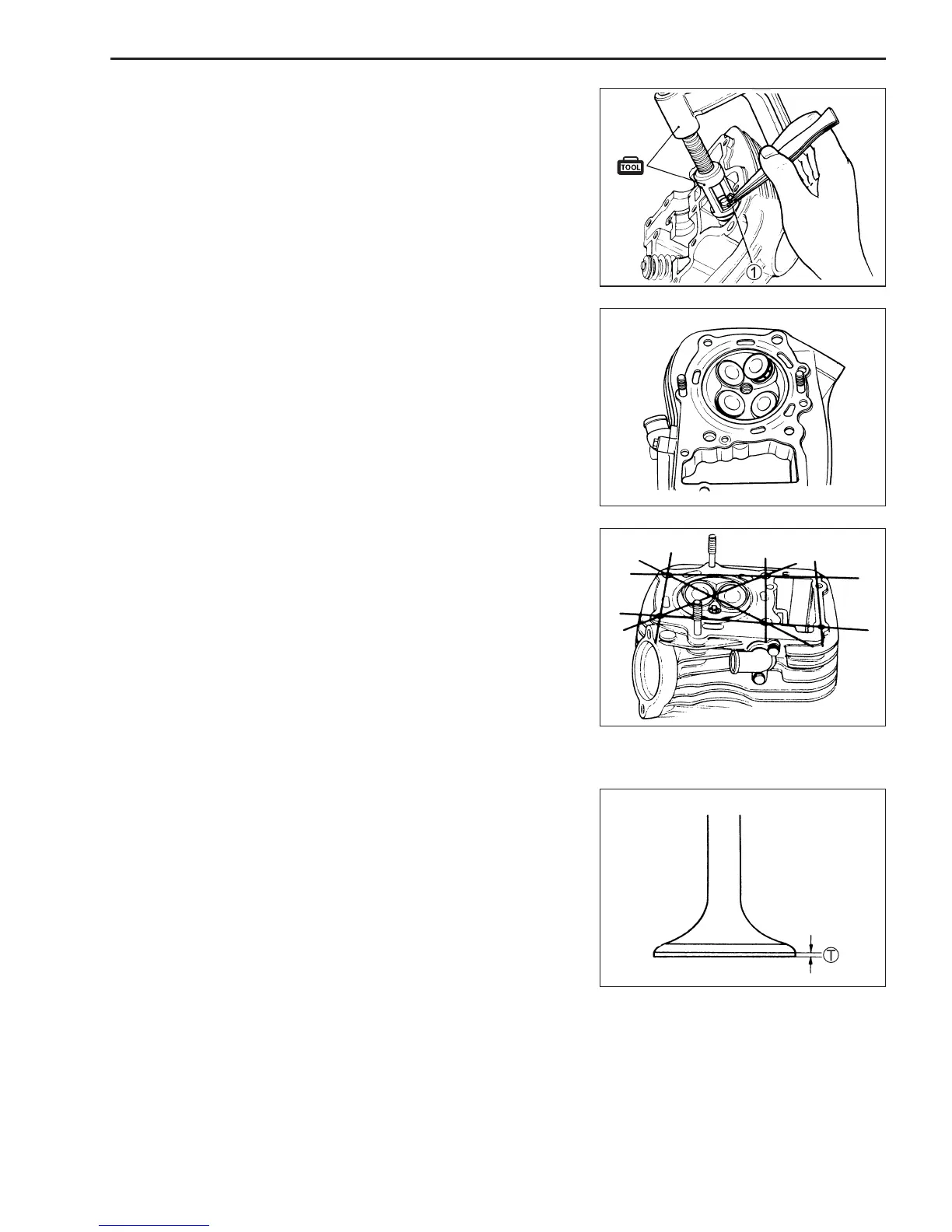

• Using special tools, compress the valve springs and remove

the two cotter halves 1 from valve stem.

% 09916-14510: Valve spring compressor

09916-14910: Valve spring compressor attachment

09916-84511: Tweezers

• Remove the valve spring retainer, inner spring and outer spring.

• Pull out the valve from the other side.

• Remove the valve stem seal and valve spring seat.

NOTE:

Removal of valves completes ordinary disassembling work. If valve

guides have to be removed for replacement after inspecting re-

lated parts, carry out the steps shown in valve guide servicing

(

!

3-27)

CYLINDER HEAD DISTORTION

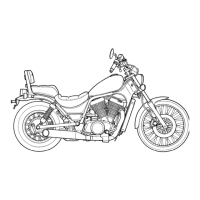

• Decarbonize the combustion chambers.

Check the gasketed surface of the cylinder head for distortion

with a straightedge and thickness gauge, taking clearance read-

ing at several places indicated. If the largest reading at any posi-

tion of the straightedge exceeds the limit, replace the cylinder

head.

" Cylinder head distortion

Service Limit: 0.05 mm (0 002 in)

% 09900-20803: Thickness gauge

VALVE FACE WEAR

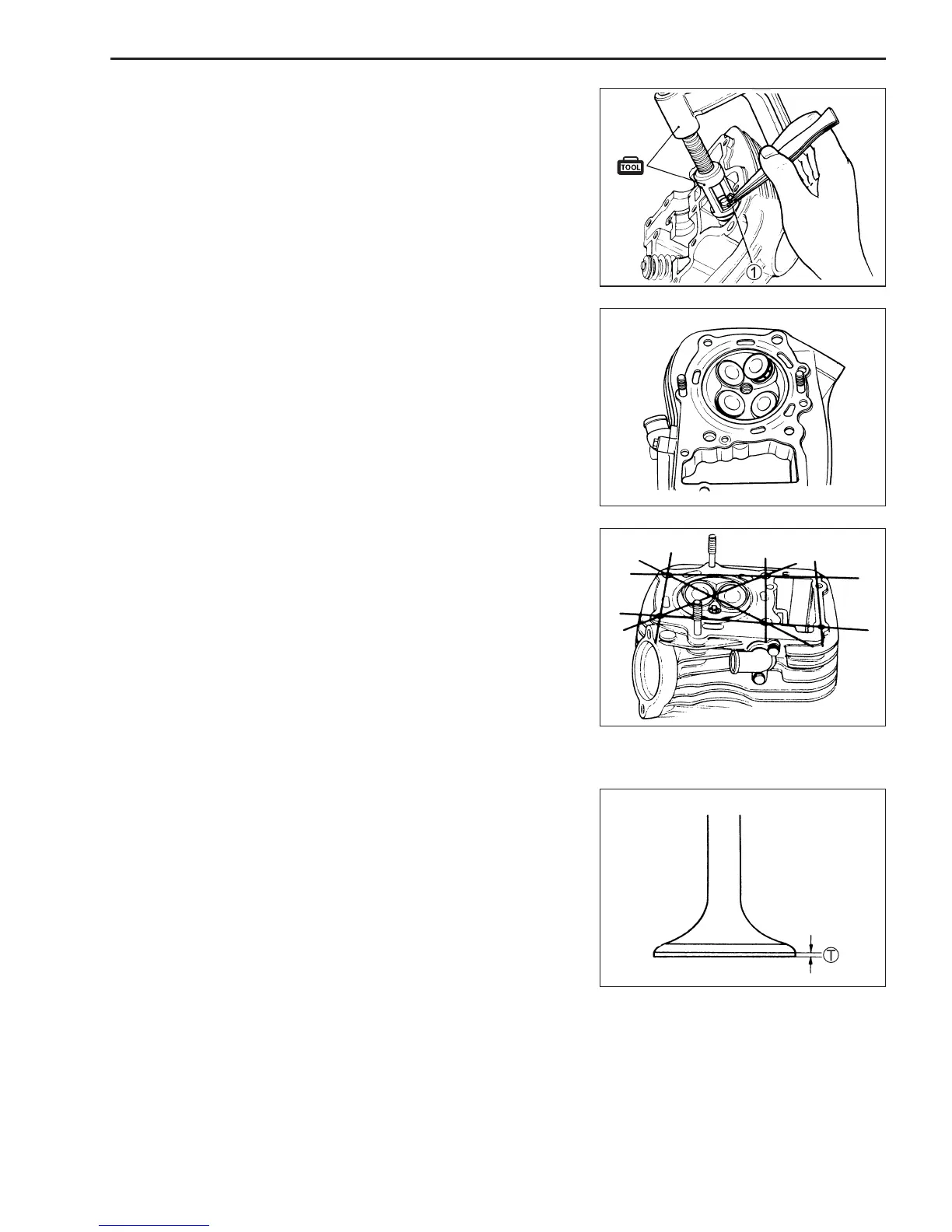

Visually inspect each valve for wear of its seating face. Replace

any valve with an abnorma ly worn face.

The thickness T decreases as the wear of the face advances.

Measure the thickness and, if the thickness is found to have been

reduced to the limit replace it.

" Valve head thickness

Service Limit T: 0.5 mm (0.02 in)

% 09900-20102: Vernier calipers

Loading...

Loading...