getting started

17

Synrad Firestar ti-Series operator’s manual

Mounting

2

Place Firestar on the mounting surface so that slots “A” and hole “B” on the base plate line up with

the tapped holes in the mounting surface.

3

Insert 1/4–20 × 5/8" UNC capscrews through Firestar’s base plate into the threaded holes of the

mounting surface. Turn the screws by hand until the threads engage.

4

Tighten all three capscrews to a torque of 5 ft lb

f

(7 N m). Do not exceed a torque of 6 ft lb

f

(8 N m)

as the base plate may be damaged.

Fasten from below

To fasten your Firestar ti-Series laser to a mounting surface from below, perform the following steps:

1

Refer to the appropriate outline and mounting drawing for dimensions and then drill three 0.261"

(6.6 mm) diameter holes into your mounting surface. Hole locations should correspond to the

threaded holes labeled “C” shown in Figure 1-3.

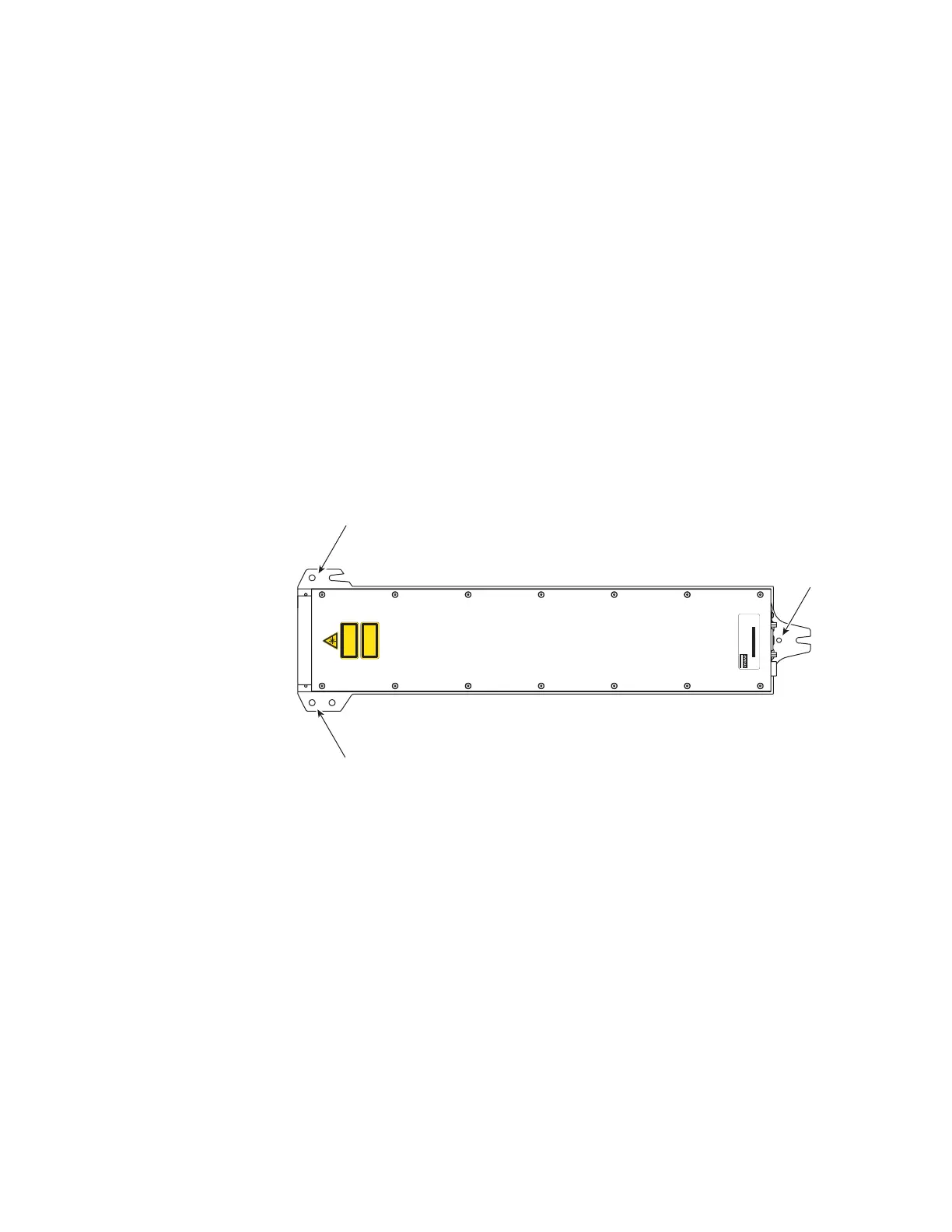

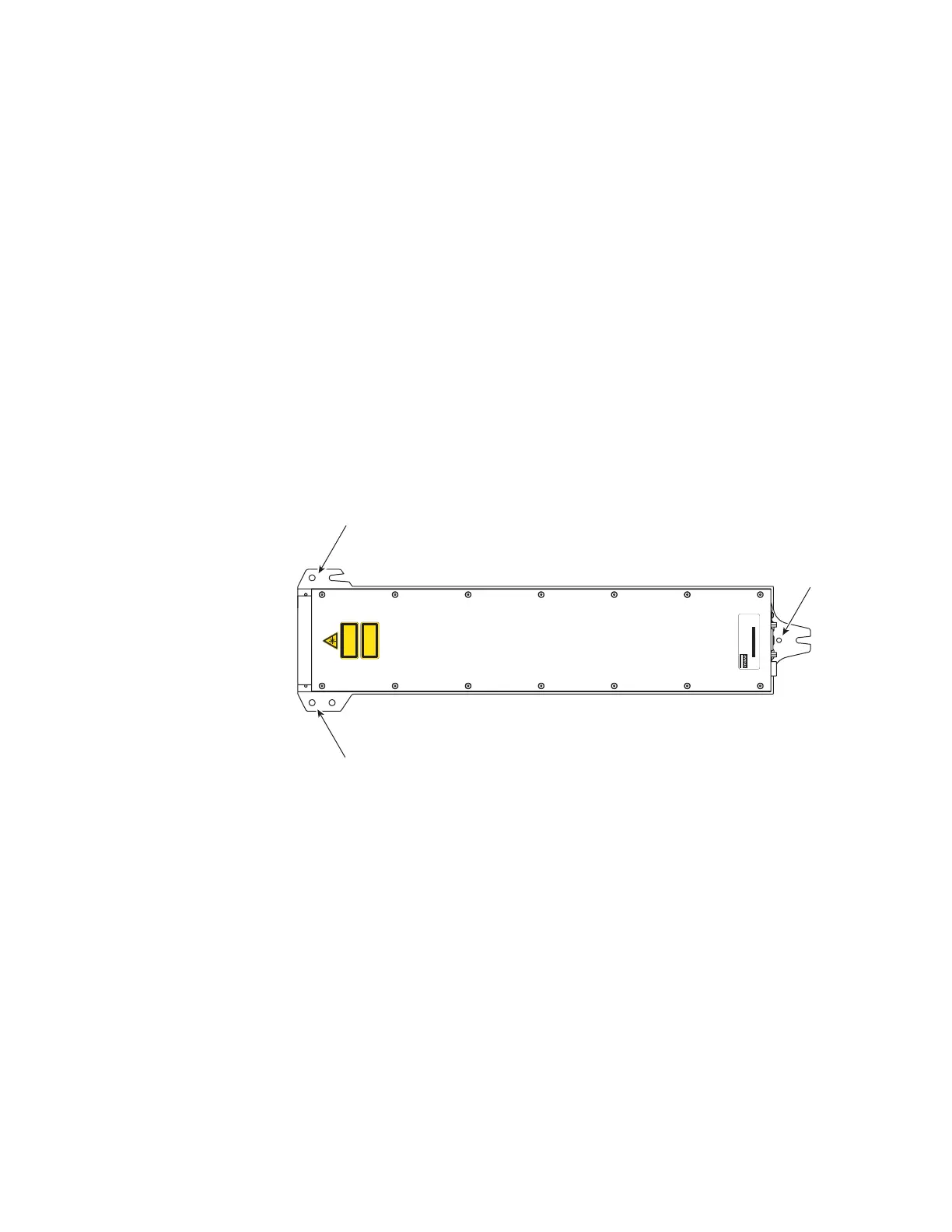

Figure 1-3 Fasten from below

2

Place Firestar on the mounting surface so that the threaded holes on the base plate (labeled “C” in

Figure 1-3) line up with the 0.261" (6.6 mm) holes drilled through the mounting surface.

3

Insert 1/4–20 × 5/8" UNC capscrews through the mounting surface into the threaded holes of

Firestar’s base plate. Turn the screws by hand until the threads engage.

4

Tighten all three capscrews to a torque of 5 ft lb

f

(7 N m). Do not exceed a torque of 6 ft lb

f

(8 N m)

as the base plate may be damaged.

INVISIBLE LASER RADIATION

AVOID EYE OR SKIN EXPOSURE TO

DIRECT OR SCATTERED RADIATION

CLASS 4 LASER PRODUCT

EN-60825-1, 1993

400 WATTS MAX

10200-10800 nm

MODEL #: FSTI60SAB

SERIAL #: TI60234080181

TESTED AT: 48V MFG: January 21, 2009

This laser component does not comply with standards for complete

laser products as specified by 21 CFR 1040.10 or IEC 60825-1.

SYNRAD, Inc. 4600 Campus Place, Mukilteo WA 98275 425.349.3500

C

C

C

Top View

(ti60 Air-Cooled Model)

Loading...

Loading...