technical reference

33Synrad Firestar ti-Series operator’s manual

Technical overview

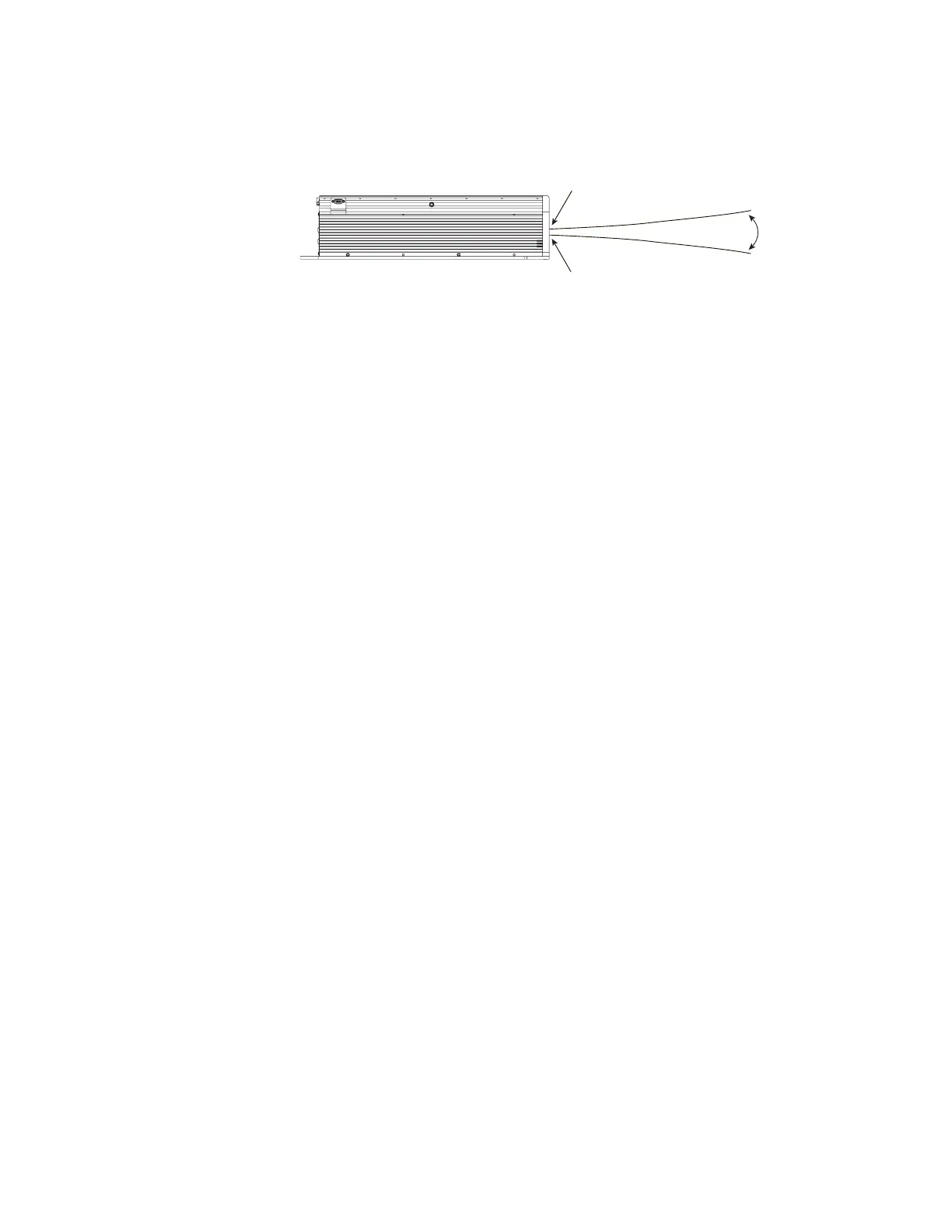

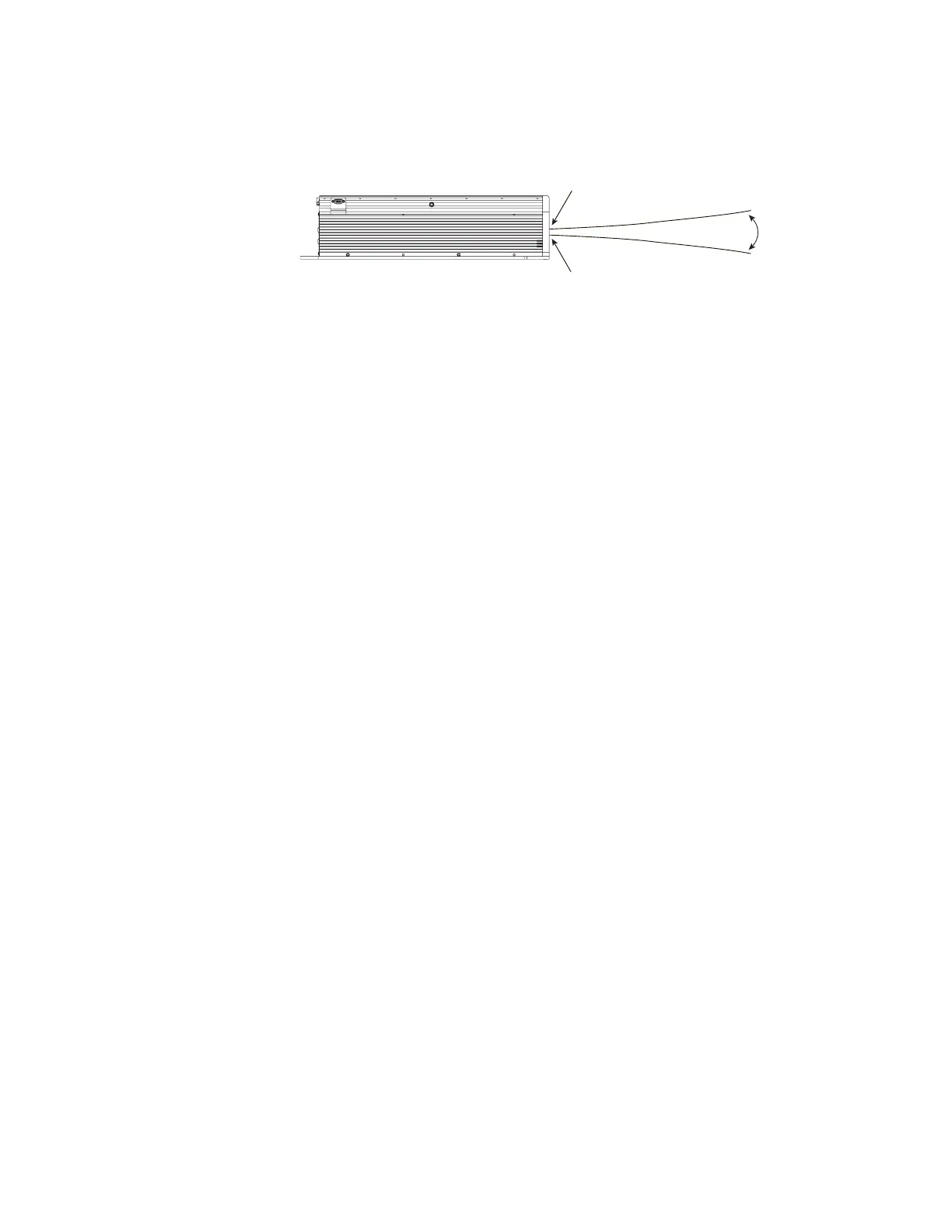

Figure 3-1 Firestar ti-Series beam characteristics

Internal RF power supply

The compact internal RF power supply converts DC input power into a radio frequency (RF) signal using

a crystal-controlled oscillator. The 82.5 MHz RF output from the oscillator is then amplified to obtain

the RF power required to drive the laser. From the amplifier, RF power is routed to the electrode structure

where it excites carbon dioxide (CO

2

) gas in the tube to produce lasing.

Control circuit

Control circuitry built into the ti-Series laser interrupts laser operation if any critical parameter is violated.

Switches and sensors monitor various conditions and parameters that, if exceeded, pose a risk of potential

damage to the laser. Additionally, laser operation is interrupted in response to the following conditions:

(1) the manual Shutter Switch is closed; (2) the Shutter Open Request signal is missing; (3) an over

temperature condition occurs; (4) the Remote Reset/Start Request signal is enabled; or (5) the Remote

Interlock signal is missing.

Optical setup

After selecting a laser for a CO

2

laser processing system, the two most important elements to consider are:

(1) beam delivery optics to transmit the beam to the work area; and (2) focusing optics to focus the beam

onto the part or material to be processed. Each element is crucial in the development of a laser-based ma-

terial processing system and each element should be approached with the same careful attention to detail.

Beam delivery optics

Divergence, or expansion, of the laser beam is important for materials processing since a larger beam

entering the focusing optic produces a smaller focused spot. Because the laser beam diverges by 7 mm over

each meter of distance traveled, the laser should be mounted a distance of 40–60 inches (1.0–1.5 m) away

from the work area and no closer than 30 inches (0.75 m) for optimum performance. Right angle turning

mirrors are often used in conjunction with the laser mounting position to obtain this distance. Figure 3-2

shows how right angle turning mirrors in a “flying optics” setup create this longer beam path.

Note: Optical components in the beam path must always be aligned to the actual beam path, not the

laser faceplate. Because of slight variations in laser construction, the beam path may not always

be centered in, or perpendicular to, the aperture in the faceplate.

Expander/collimators are optical devices that reduce laser divergence while at the same time increasing

beam diameter by a selectable magnification factor. Adding an expander/collimator to the “flying optics”

setup shown above would substantially reduce beam divergence and any variance in beam diameter caused

by the changing optical path length. In fixed-length delivery systems where the laser is positioned only one

meter away from the focusing optic and a small spot size is required, an expander/collimator is again the

best solution to provide the required beam expansion before reaching the focusing optic.

Beam Waist Diameter 2.2 mm

at Out

put Aperture

Full Angle Divergence <7 mrad

Ø

Loading...

Loading...