12—9

Residual‐current‐operatedprotectivedevices

Terminal

Function / connection

L1, N, PE

Mains connection for 1 ~ types (observe the line voltage indicated

rating plate).

L1, L2, L3, PE

Mains connection for 3 ~ types (observe the line voltage indicated

rating plate).

11, 14

Relay output “K1” for fault indication.

*

•

For operation the relay is energized,

connections

“11”

and

“14”

are bridged. For fault the relay is de-energized (

Diagnostics / faults).

•

When switching off via enable (D1 = Digital In 1), the relay remains

energized.

E1, GND

Analog input for setting speed via 0 - 10 V or PWM signal

*

10V

Voltage supply for speed setting by 10 kΩ potentiometer.

24V

Voltage supply for external devices.

D1, +24V

Digital input for enable.

*

•

Device

“ON”

for closed contact.

•

Controller

“OFF”

with opened contact.

*Functionforstandardfactorysetting,differentpresettingpossible.

UL:Input(Line)

•

Cu connection leads with the following specifications must be employed:

– Minimum insulation temperature of 80 °C

– Terminal tightening torque for field block (L1, N, and/or L1, L2, L3) of 5 - 7 Lb In.

(Exception: spring-cage terminal for motor size "G" @ line voltage 3 ~ 200...240 V) – Terminal tightening

torque of 4.5 Lb In for field block (K1).

– Terminal tightening torque of 4.5 Lb In for all other field blocks.

– Terminal tightening torque of 2.2 Lb In for add-on modules.

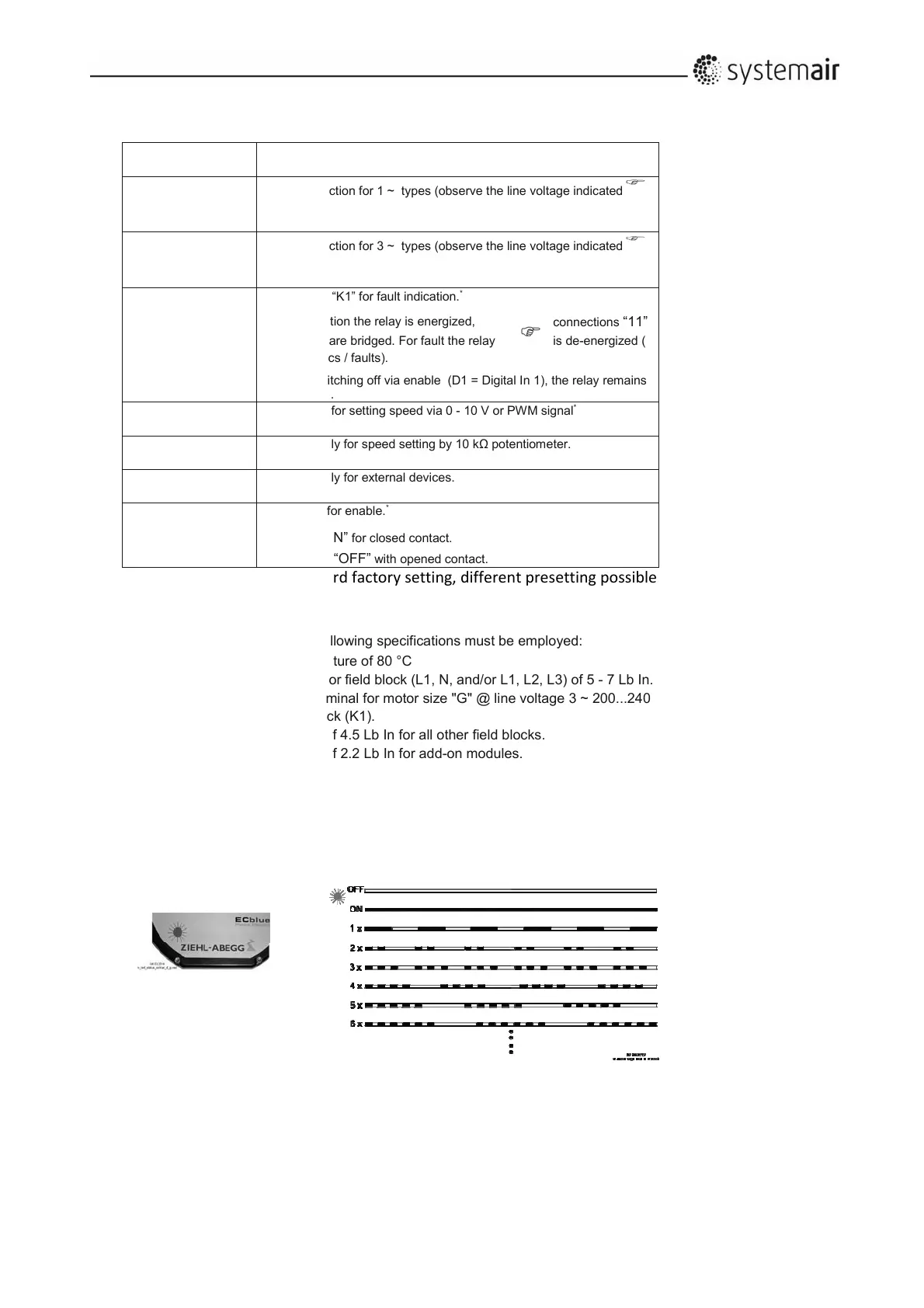

12.5.2Diagnostic/faults

Status Out with flash code

Loading...

Loading...