Taco® SKV

16

302-365, Effective: June 5, 2017

© 2017 Taco, Inc.

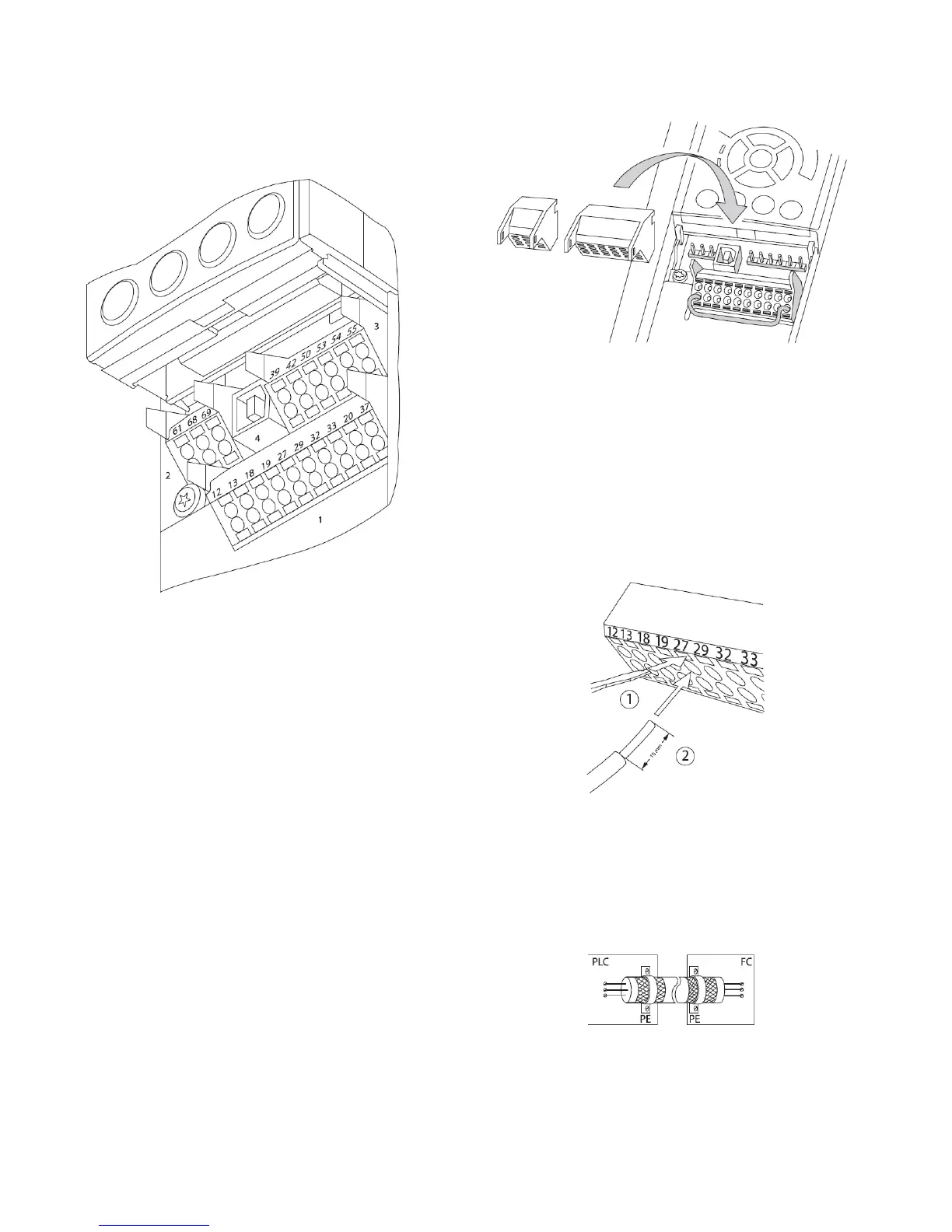

Control Terminal Types

Figure 8-14 shows the removable adjustable frequency

drive connectors.

Figure 8-14: Control Terminal Locations

• Connector 1 provides four programmable digital

inputs terminals, two additional digital terminals pro-

grammable as either input or output, a 24V DC termi-

nal supply voltage, and a common for optional

customer supplied 24V DC voltage.

• Connector 2 terminals (+)68 and (-)69 are for an RS-

485 serial communications connection.

• Connector 3 provides two analog inputs, one analog

output, 10V DC supply voltage, and commons for the

inputs and output.

• Connector 4 is a USB port available for use with the

MCT-10 Set-up Software.

• Also provided are two Form C relay outputs that are

in various locations depending upon the adjustable

frequency drive configuration and size.

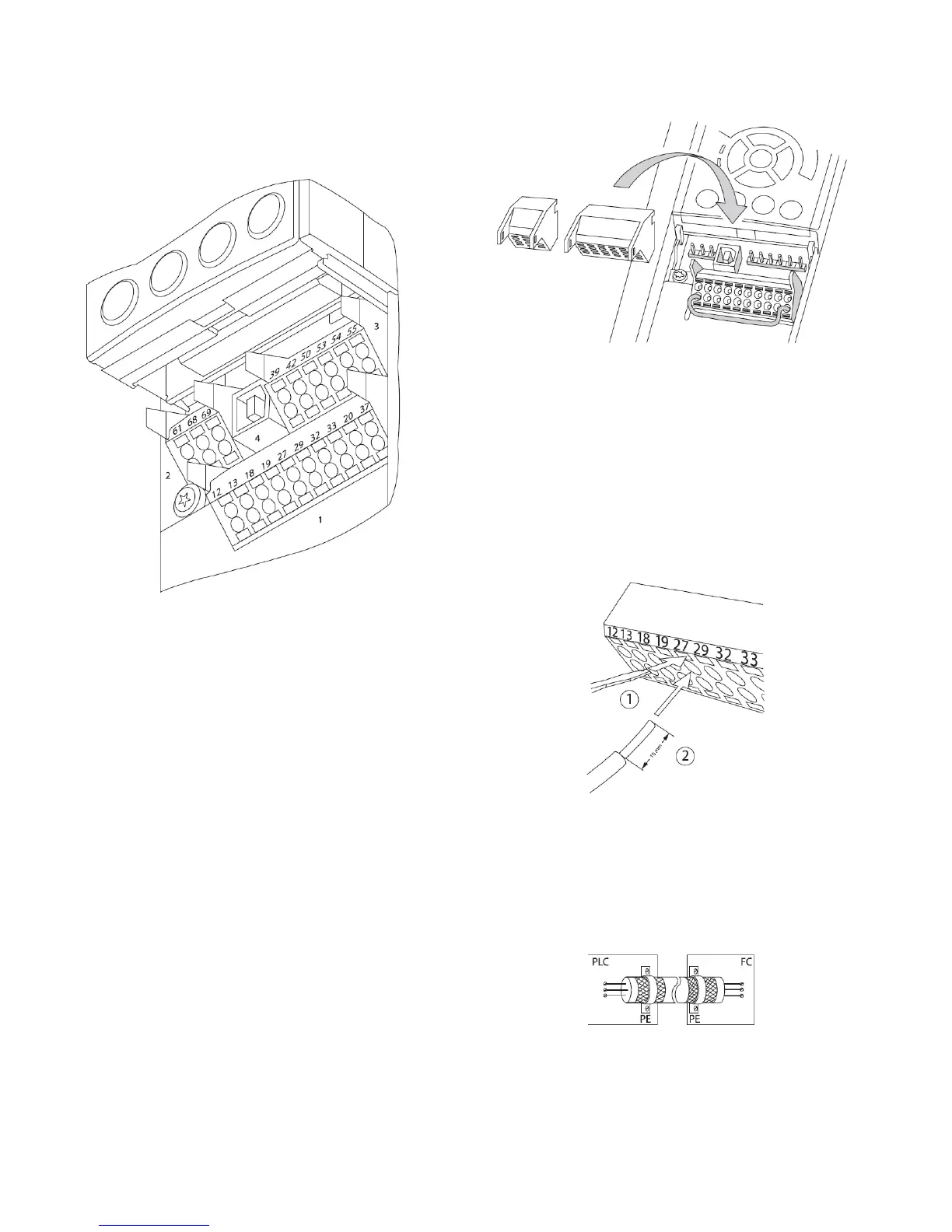

Wiring to Control Terminals

Control terminal connectors can be unplugged from the

adjustable frequency drive for ease of installation, as

shown in Figure 8-15.

Figure 8-15: Unplugging Control Terminals

1.Open the contact by inserting a small screwdriver

into the slot above or below the contact, as shown

in Figure 8-16.

2.Insert the bared control wire into the contact.

3.Remove the screwdriver to fasten the control wire

into the contact.

4.Ensure the contact is firmly established and not

loose. Loose control wiring can be the source of

equipment faults or less than optimal operation.

Figure 8-16: Connecting Control Wiring

Using Shielded Control Cables

Correct Shielding

The preferred method in most cases is to secure control

and serial communication cables with shielding clamps

provided at both ends to ensure best possible high fre-

quency cable contact.

Loading...

Loading...