Taco® SKV

27

302-365, Effective: June 5, 2017

© 2017 Taco, Inc.

* To use AI 53, configure parameters 6-14, 6-15, 6-17 and set 20-00 to Analog Input 53

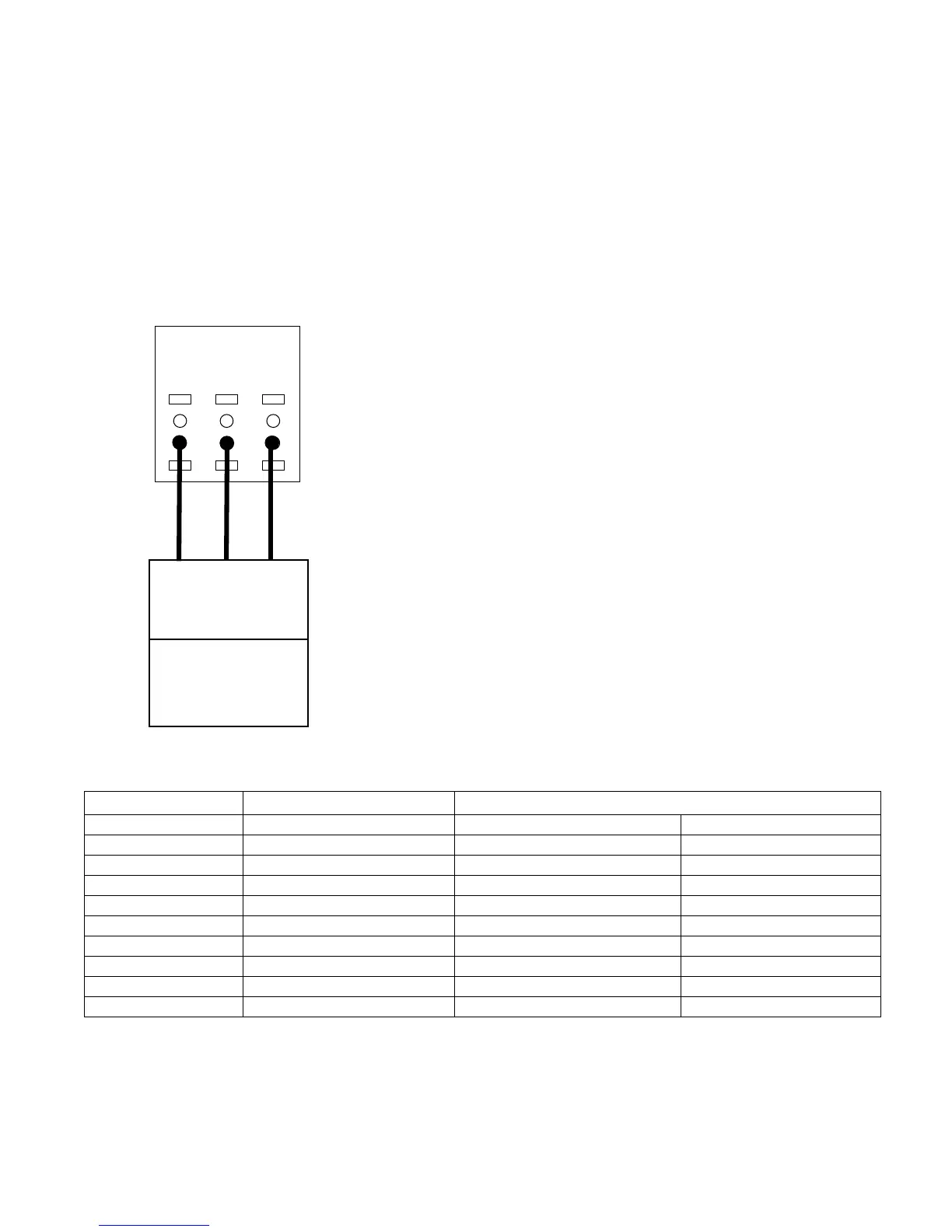

8.4.6 Control From External PLC/BMS Using Communications Port

The controller can be controlled from a BMS or PLC through the communications port. In this configuration, the BMS or

PLC overrides the setpoint to control the drive. Control cables must be braided screened/shielded and the screen must

be connected to the metal cabinet of the controller using two cable clamps (one at each end). The bus connections

must be terminated by turning the BUS TER switch to the on position. This switch can be found under the LCP, when

the LCP is detached.

This wiring scheme is used with Set-up 2, as shown in “10.1 SelfSensing Description” on page 34.

Figure 8-25: Terminal Connections for External Control via Communications Port

69

-

68

+

61

SHLD

Comm Port

SHLD

-

RS485

Controller

[8-**] Config params

+

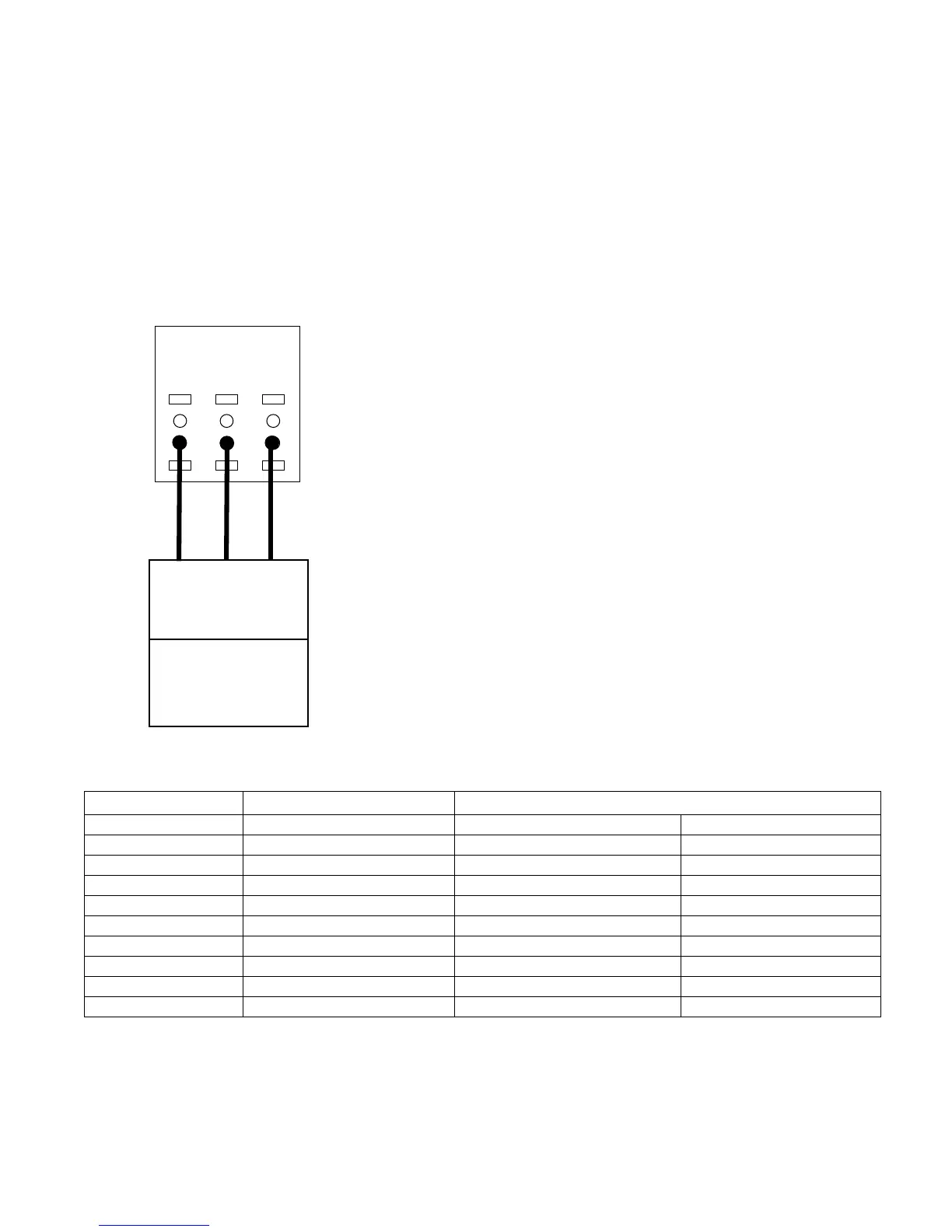

Table 7: Parameter settings for Modbus RTU and BACnet protocols

The parameters above show a typical scenario used for Modbus RTU or BACnet protocols. The parameters must be

set as appropriate for the devices on the network. 8-32 Baud Rate and 8-33 Parity/Stop Bit should be set to match the

other devices on the network. For specific communication set-up information for Modbus RTU, refer to the document

number MG92B102. For specific communication set-up information for BACnet, see documents MG14C102 and

MG11D202. These documents can be downloaded from www.danfoss.com.

Parameter Number Parameter Description Protocol

Modbus RTU BACnet

8-02 Control Source FC Port FC Port

8-30 Protocol Modbus RTU BACnet

8-31 Address 1 1

8-32 Baud Rate 19200 9600

8-33 Parity/Stop bit Even Parity, 1 Stop bit No Parity, 1 Stop bit

8-34 Estimated cycle time 0 ms 0 ms

8-35 Minimum Response Delay 10 ms 10 ms

8-36 Maximum Response Delay 5000 ms 5000 ms

8-37 Maximum Inter-Char Delay 0.86 ms 25 ms

Loading...

Loading...