Taco® SKV

26

302-365, Effective: June 5, 2017

© 2017 Taco, Inc.

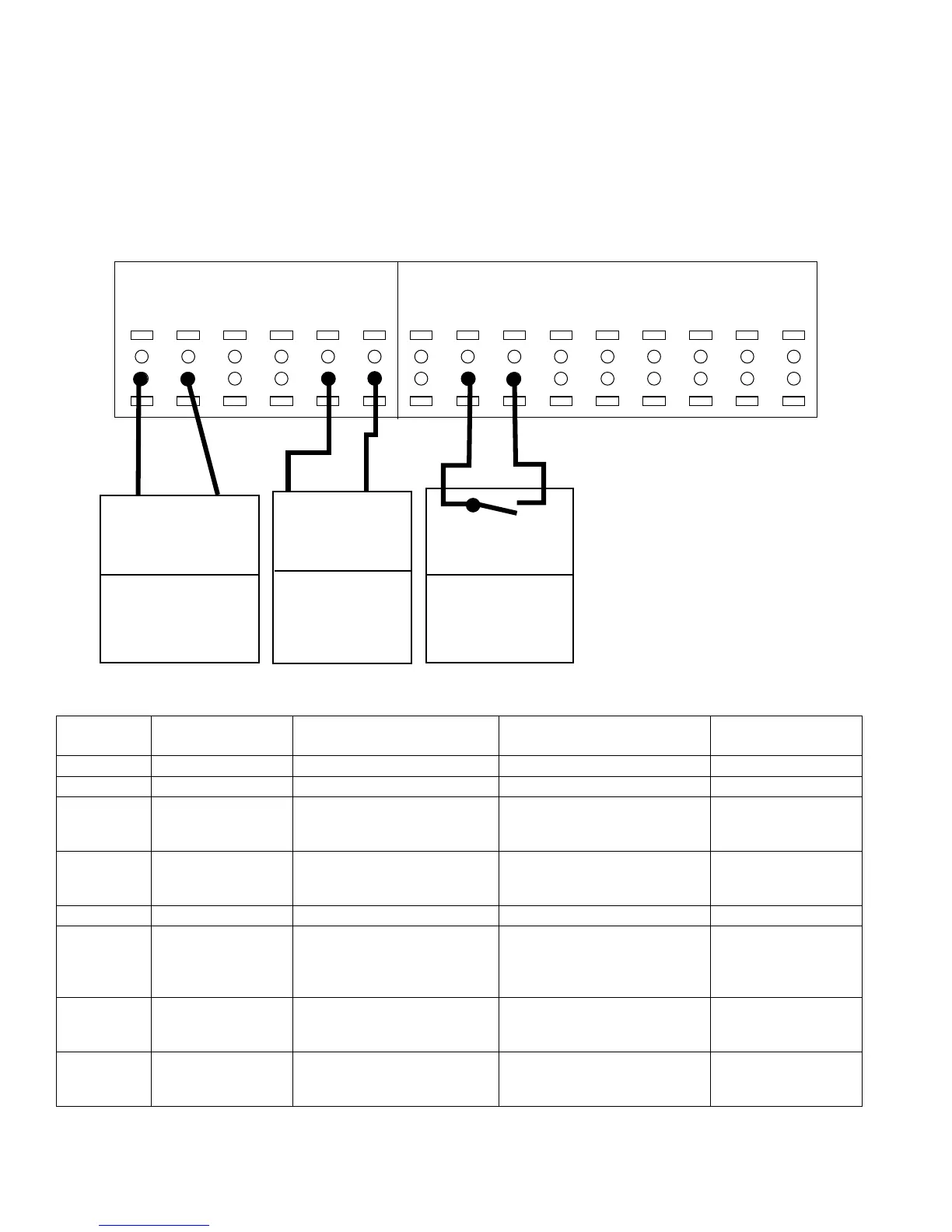

8.4.5 Control from external PLC/BMS through Analog Input

This set-up allows an external control source such as a PLC or BMS controller to provide: a) the process variable, b)

the setpoint or c) a speed reference. The output from the external control device can be either a voltage or current sig-

nal. The analog input configuration switches must be set to the correct type of output signal. The drawing below shows

the connections for this configuration.

This wiring scheme is used with Set-up 2, as shown in “10.1 SelfSensing Description” on page 34.

Figure 8-24: Terminal Wiring for External Control Source

39

COM

42

AOUT

50

+10V

53

A IN

55

COM

54

A IN

12

+24V

13

+24V

18

D IN

19

D IN

27

D IN

29

D IN

32

D IN

33

D IN

20

COM

I/O Analog I/O Digital

COM

AI

Unit Receiving

Analog Output

[6-50]

[137] Speed*

4-20 mA

* factory default

Starting/Stopping

Controller

[5-10]

[8] Start*

Start: Closed

* factory default

AO

COM

PLC or BMS

Control Signal

[Group 6-]

[Group20-]

(See Table)

Set A54=U for 0-10V

Set A54=I for 4-20mA

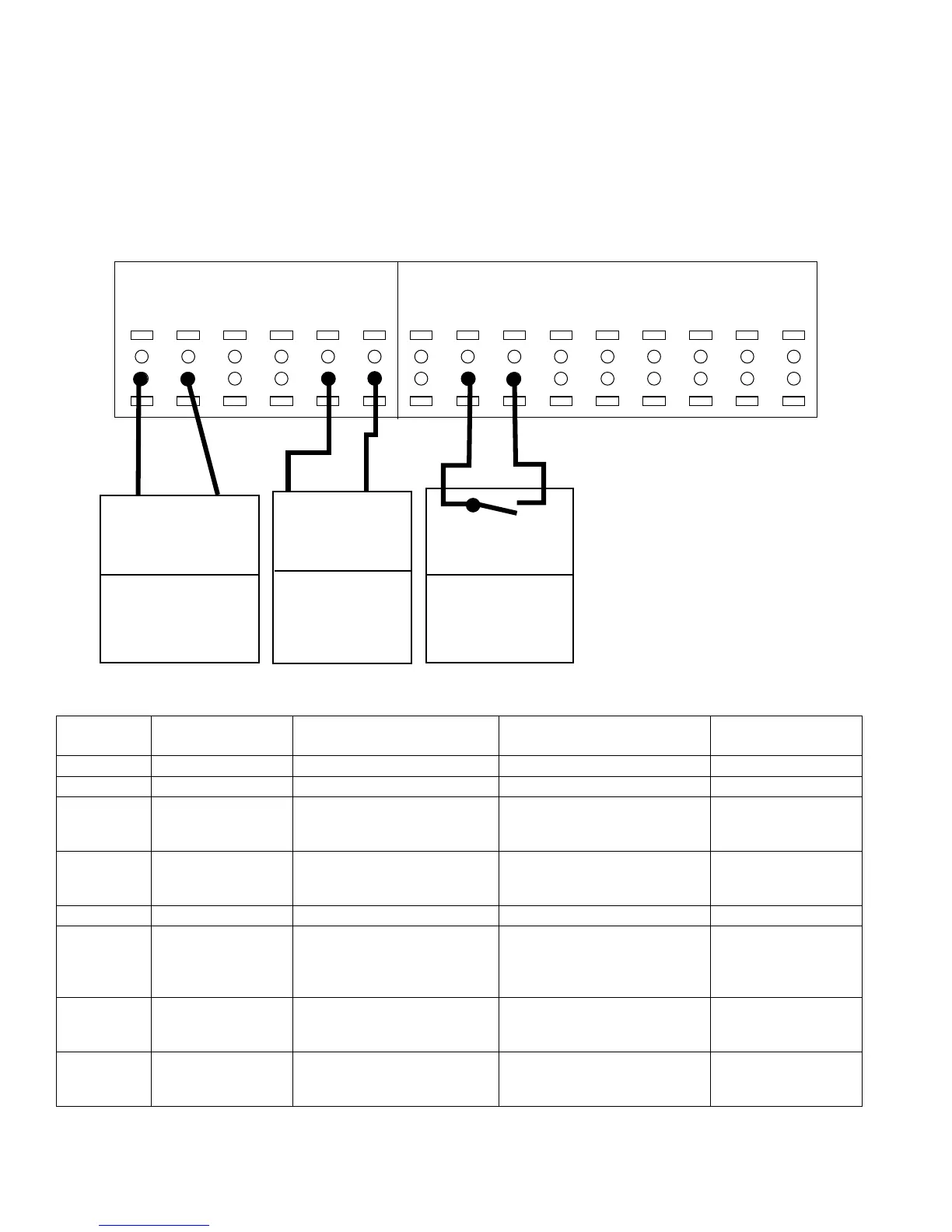

Table 6: Parameter Configuration for Use of an External Control Signal

Parameter

Number

Parameter

Description

For process variable from

BMS/PLC*

For setpoint from BMS/ PLC**

For speed reference

from BMS/PLC***

1-00 Configuration Mode Closed Loop Closed Loop Open Loop

3-15 Reference 1 Source No Function Analog Input 54* Analog Input 54*

6-24 Terminal 54 Low Ref./

Feedb. Value

Minimum value of process vari-

able. For example, for a 0-60PSI

transducer, set to 0.

Minimum reference/setpoint

value. For example, for a 0-

60PSI DP transducer, set to 0.

Minimum motor speed.

For example, 0 RPM.

6-25 Terminal 54 High

Ref./Feedb. Value

Maximum value of process vari-

able. For example, for a 60PSI

transducer, set to 60.

Maximum reference/setpoint

value. For example, for a 60PSI

DP transducer, set to 60.

Maximum motor speed.

For example, 2950

RPM.

6-27 Terminal 54 Live Zero Enabled Enabled Disabled

20-00 Feedback 1 Source Analog Input 54 Select as appropriate for applica-

tion. This can be any selection

except the setting of parameter

3-15.

No Function

20-12 Reference/Feedback

Unit

Select as appropriate for appli-

cation. For example, set to PSI

when using pressure feedback.

Select as appropriate for applica-

tion. For example, set to PSI

when using pressure reference.

NA

20-14 Maximum Reference/

Feedback

Maximum transducer feedback

value. For example, for a 60PSI

transducer, set to 60 PSI.

Maximum reference/setpoint

value. For example, for a 60PSI

transducer, set to 60 PSI.

NA

Loading...

Loading...