88

MAINTENANCE

Service Data

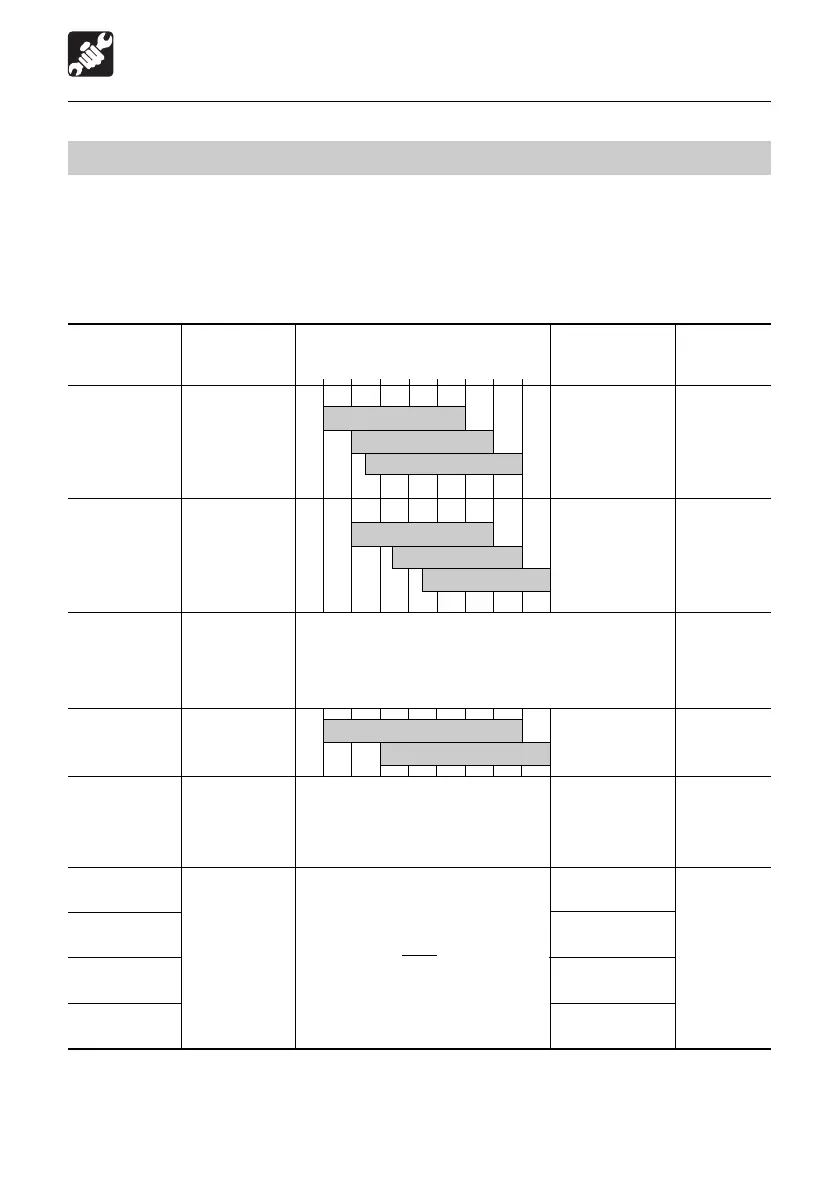

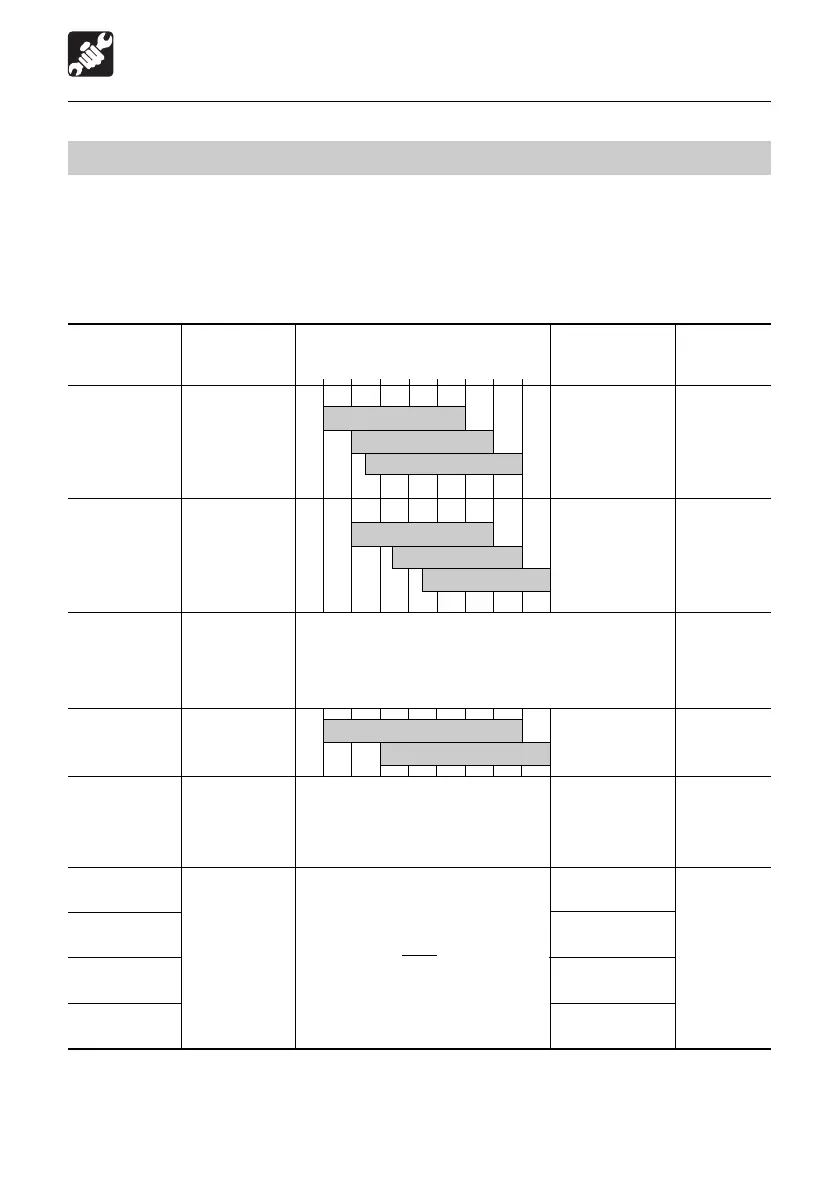

Fuel and Lubricant Chart

Use different fuels, lubricants and greases according to the temperature, referring to the

chart below.

¡ Change the lubricant earlier than as shown in the table if it is extremely dirty or its

performance has deteriorated severely.

¡ Whenever possible, use the same brand of lubricant as before. If changing with a different

brand, replace the entire quantity – do not mix different brands.

* For water, use tap water (soft). Do not use well or river water.

** When the ambient temperature drops below 0°C, add coolant (antifreeze). Follow the

coolant manufacturer’s instructions to determine the mixture ratio.

Part

Type

Type by temperature

-22 -4 14 32 50 68 86

104

°F

-30 -20 -10 0 10 20 30 40°C

Replacement

interval

Capacity

R(US. qt.)

Engine oil

pan

Diesel

engine oil

API - CD

After first 50

hrs.

Every 250 hrs.

Upper limit:

1.7 (1.8)

Lower limit:

1.0 (1.1)

System: 14

(3.7 U.S.gal)

Tank: 7.3

(1.9 U.S.gal)

Hydraulic

tank

Antiwear

hydraulic oil

Every 2000 hrs.

Use a clean, Quality fuel for good performance and optimum engine life.

¡ To prevent fuel flow problems in cold weather, use diesel fuel with a pour point of

at least -12°C (10°F) below the lowest expected ambient temperature.

¡ Minimum cetane number is 45. Low temperature or high altitude operation may

require the use of fuel with a higher cetane number.

Fuel tank

Diesel fuel

Tank: 8

(2.1 U.S.gal)

Engine

cooling

system

Coolant

(water * +

coolant **)

Every 1000 hrs.

2.8 (3.0)

SAE 5W-20

SAE 10W-30

SAE 15W-40

Travel

reduction

gear

Gear oil

API-GL-4

SAE 90

After first 250

hrs.

Every 1000 hrs.

0.33 (0.35)

each

Slew motor

pinion

Slew

bearing

Working

equipment

Levers

Lithium

based

grease

EP-2

NLGI No. 2

Every 50 hrs.

Every 50 hrs.

Daily or every

10 hrs.

When required

As

required

ISO VG32

ISO VG46

ISO VG68

50% coolant mixture

30% coolant mixture

Loading...

Loading...