- 53 -

3. CONTROL SYSTEM

Fig. 3.13

Fig. 3.15

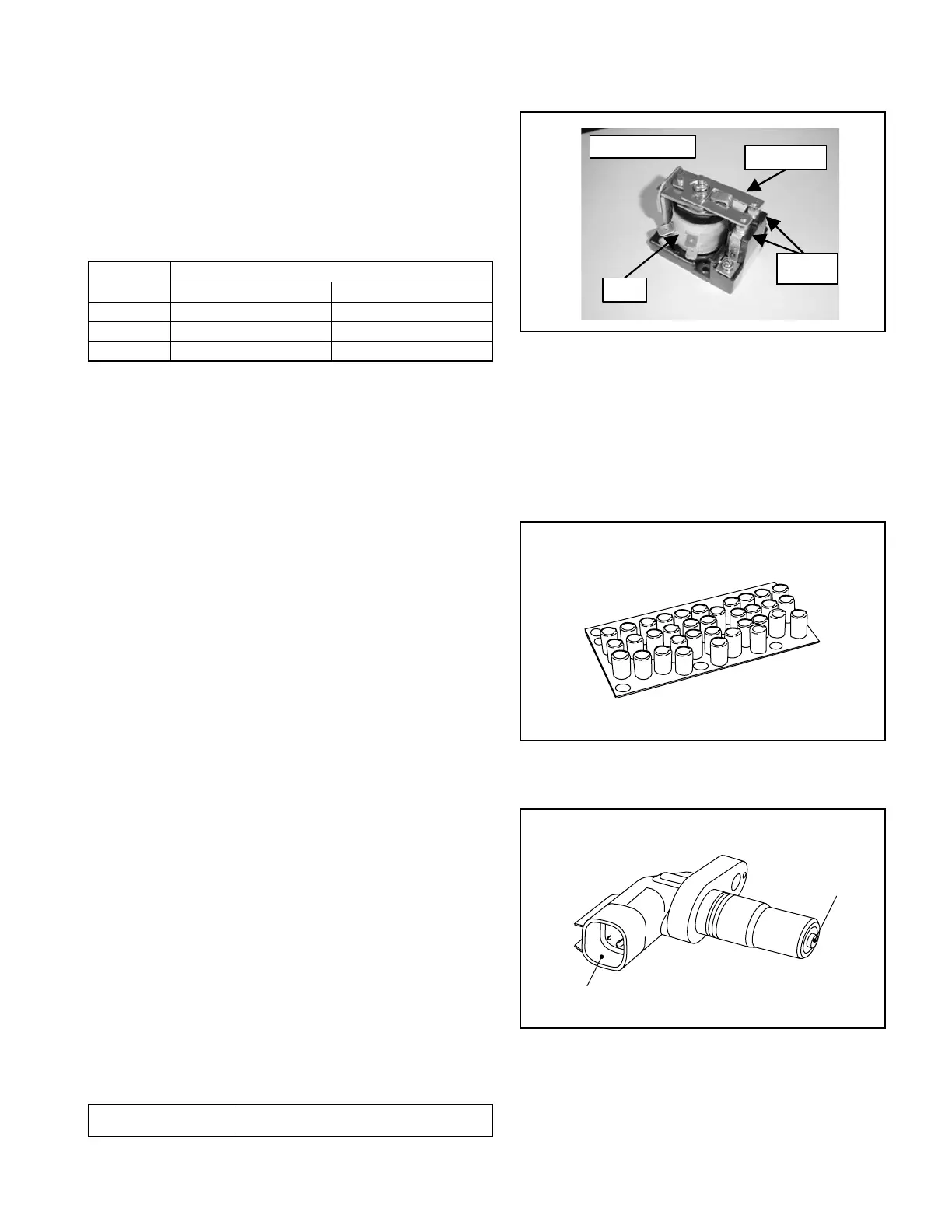

(2) Checking contactor coils

①

Remove the coil wiring connector.

②

Set the tester to a resistance range of 100 Ω and

measure the resistance between terminals using

the tester.

③

Judgewhetherthecoilisgoodornotusingthe

measured values.

Contactor

Judgment

Good Defective

MD 20-50Ω (typ, 30 Ω) ∞ Ω (broken coil)

MP 20-50Ω (typ, 30 Ω) ∞ Ω (broken coil)

MPS 120-380Ω (typ, 266 Ω) ∞ Ω (broken coil)

CONTACT

SENSOR

CONNECTOR

(3) Checking contactor contact points

①

Visually check the contactor contact points for roughness on the surface.

②

Replace any contactor with excessively rough or worn surface, with a new one.

8. Checking capacitor boards (CBD, CBP)

The capacitor board consists of multiple

aluminum electrolytic capacitors connected in

parallel,andinstalledjustabovetheFETpower

module. These capacitor boards absorb a surge

voltage generated from the FET power module to

prevent damage to the FET.

①

Visually check for scores, scratches or excessive

discoloration.

②

Replace any defective capacitor board with a

new one.

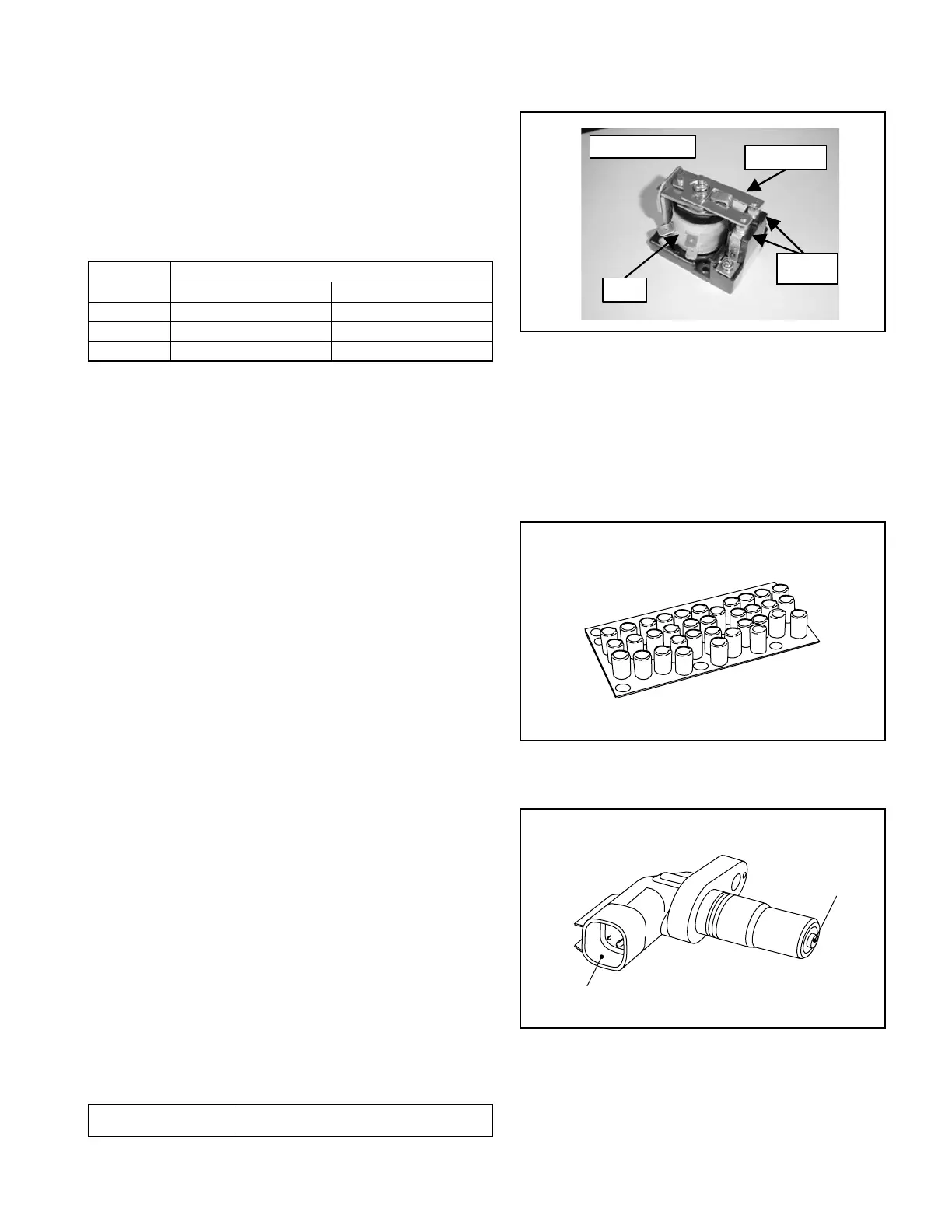

9. Checking motor speed sensor

The magnetic induction sensor is generates

alternating current per pitch of toothed rotor attached

to the side opposite the side to which the motor shaft

is directly connected.

Two magnetic induction sensors are used for the

traveling motor.

①

Remove the tester.

②

Set the tester to a resistance range of x 100

Ω and measure the resistance between sensor

terminals, using the tester.

③

Judgewhetherthesensor is goodornotusing

the measured values.

Normal value approx. 620 Ω (20°C)

MPS CONTACTOR

MOVABLE

CONTACT

COIL

Loading...

Loading...