4-40

09- 07 PID Output Lag Filter Time

Range

【0.0~2.5】Sec

09-07:Update time for output frequency.

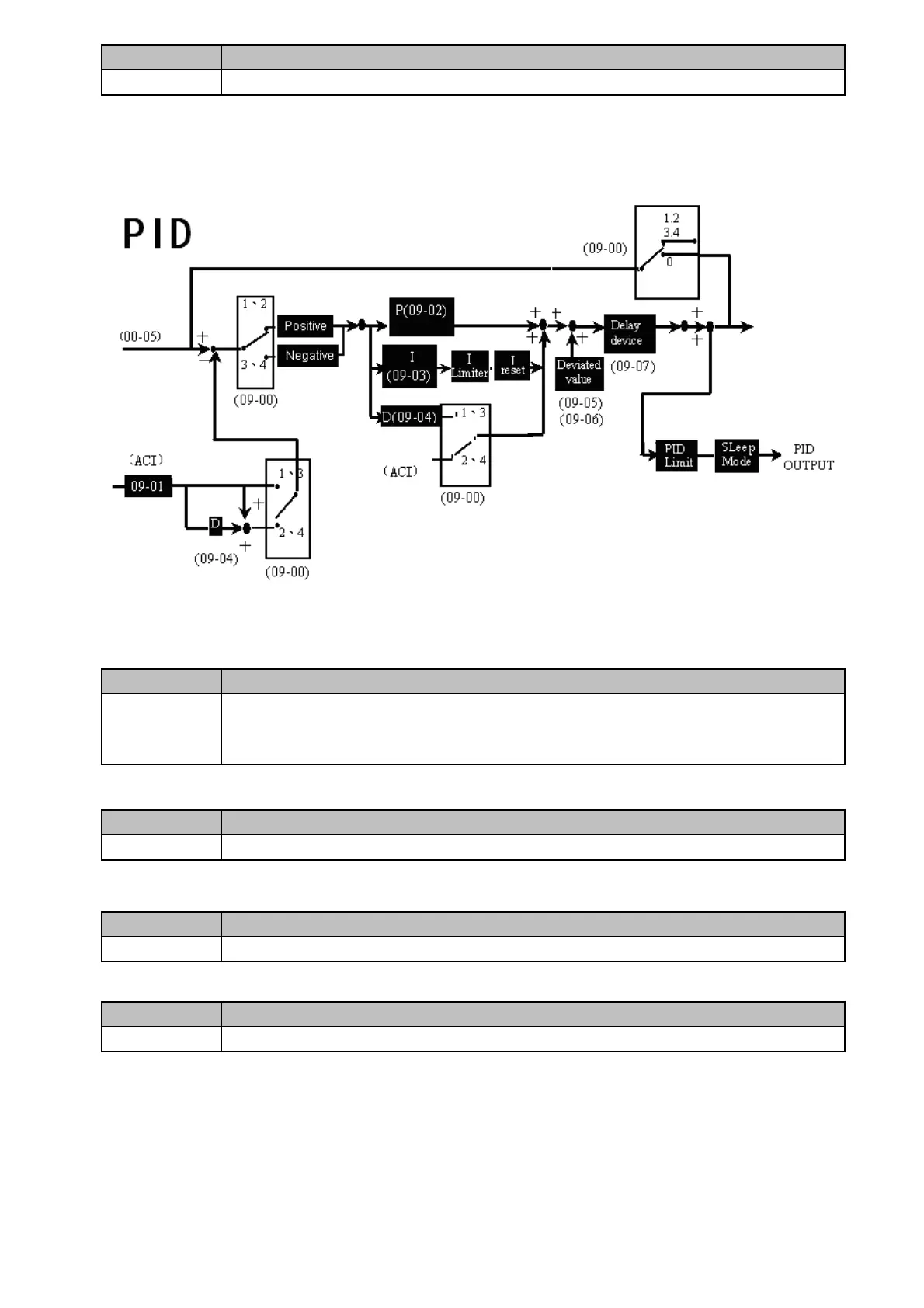

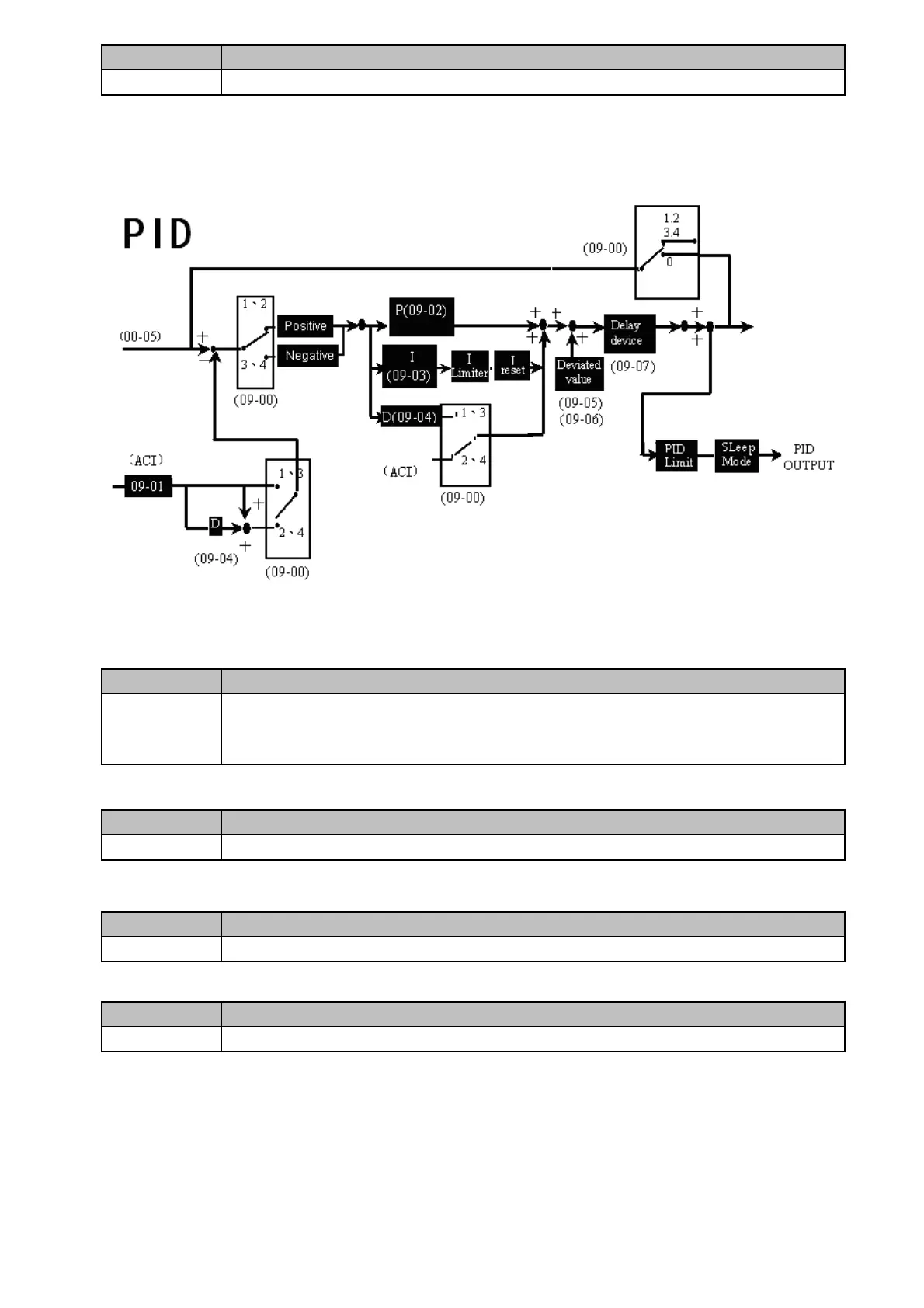

※Note:PID is used for the control of output flow of the converter, the control of external fan air

volume and temperature control, and the control flow is as

follows:

1) When performing PID control, please set the terminal ACI on TM2 as the PID feedback

signal, i.e. 02-06=0.

2) The set value described above is the frequency of the input set from 00-05/00-06.。

09- 08 PID Feedback Loss Detection Mode

Range

【0】:Disable

【1】:Enable – Drive Continues to Operate After Feedback Loss

【2】:Enable – Drive “STOPS” After Feedback Loss

09-08= 0: Disable; 09-08= 1: detect, continue running, and display ‘PDER’;09-08= 2: detect,

stop, and display ‘PDER’。

09- 09

Feedback Loss Detection Level

Range

【0~100】%

09-09: is the level for signal loss. Error = (Set point – Feedback value). When the error is larger

than the loss level setting, the feedback signal is considered lost.

09-10:the minimum time to consider the feedback signal lost.

09-11:the Limiter to prevent the PID from saturating.

09- 10

Feedback Loss Detection Delay Time

Range

【0.0~25.5】Sec

09- 11

Integration Limit Value

Range

【0~109】%

Loading...

Loading...