Controls and Operating

3-31

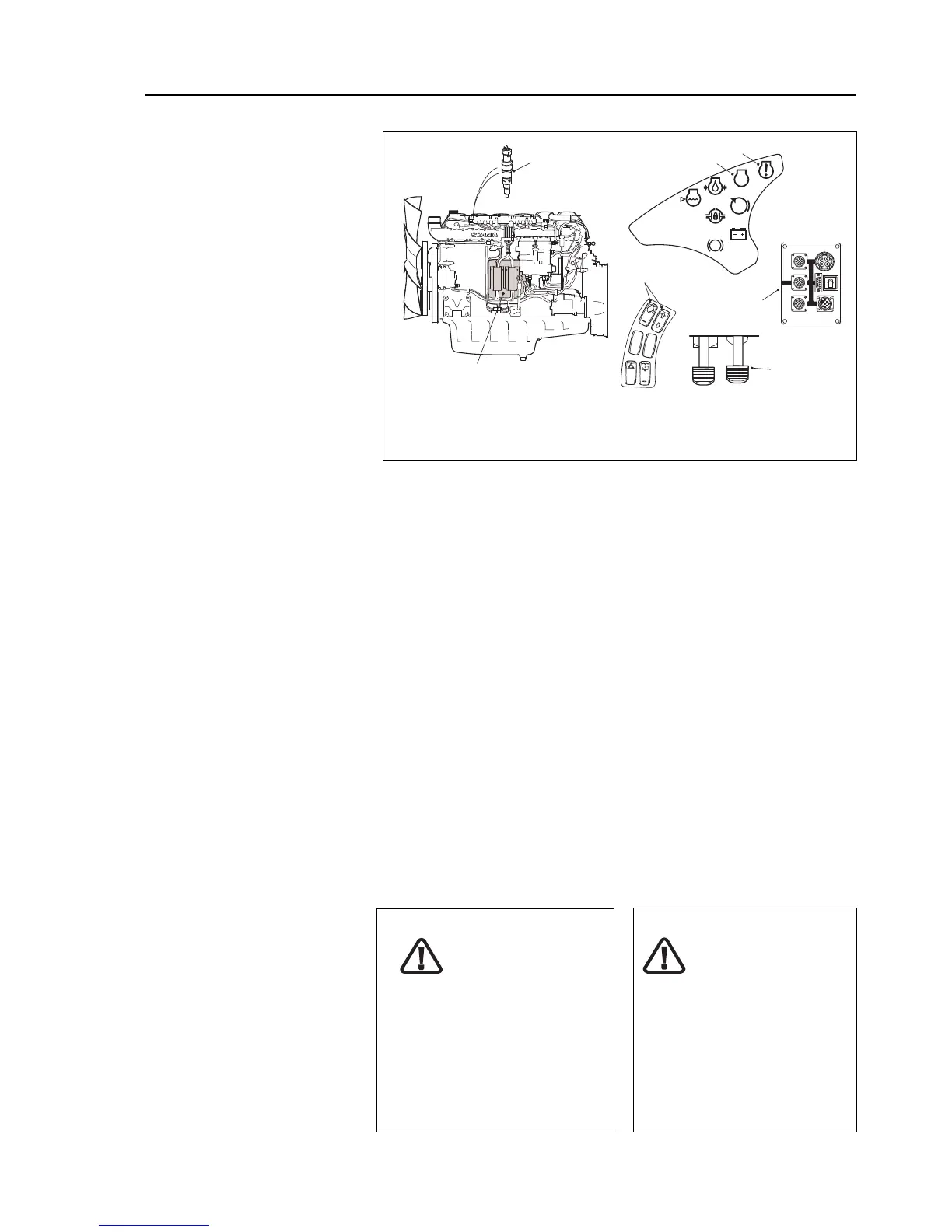

PDE Fuel Injection System - Description

1. Engine Management System (EMS) - Receives electronic inputs

from the driver as well as from sensors that provide information

electronically, such as speed, oil pressure and temperature, boost

pressure and temperature and coolant temperature. This information is

used to control both the quantity of fuel injected and the injection

timing. The EMS is programmed to control the horsepower rating,

torque curve, maximum engine speed and engine protection devices.

The EMS processes this information and sends electronic signals to

the PDE Fuel System Injectors where the precise amount of fuel is

injected into the engine.

2. PDE Fuel Injectors - The engine is equipped with high pressure

(PDE) injectors that inject diesel fuel directly into the combustion

chamber. The amount of fuel injected and the beginning of injection

timing is determined by the engine control unit.

NOTICE: Never apply 12 or 24 volts directly to the terminals on the

injectors or engine sensors as they will burn out. Before removing

injectors, the fuel passages must be blown out to prevent fuel flow from

entering the cylinder head.

P

STOP

X14

X4

X36

X35

X34

S25

X44

5

3

7

4

MOT00306

6

2

1

WARNING

Engine or electronic system

diagnosis must be done by a

person other than the opera-

tor. The operator must main-

tain control of the moving

machine while the assistant

performs the diagnosis.

The operator of the machine

must not attempt to use or

read an SDP3 of any kind while

the machine is operating.

Doing so can result in loss of

control, which may cause

machine damage and may

result in personal injury.

WARNING

Loading...

Loading...