9-17 TA9 & TA10 Dumper 0803-3 December 2010

Maintenance

Front and Rear Axles

Axle Description

Totally enclosed sealed multi-plate brake axles are fitted, which

have automatic compensation for wear of the friction discs.

Normal servicing is limited to lubrication as detailed in the

schedule in the Maintenance section, details of procedures for

major repairs may be obtained from the manufacturer.

Over a period of time wear may necessitate replacement of the

friction discs and/or the slave cylinder seals.

These parts should be replaced as required and the system bled.

Axle Oil - Checking Level

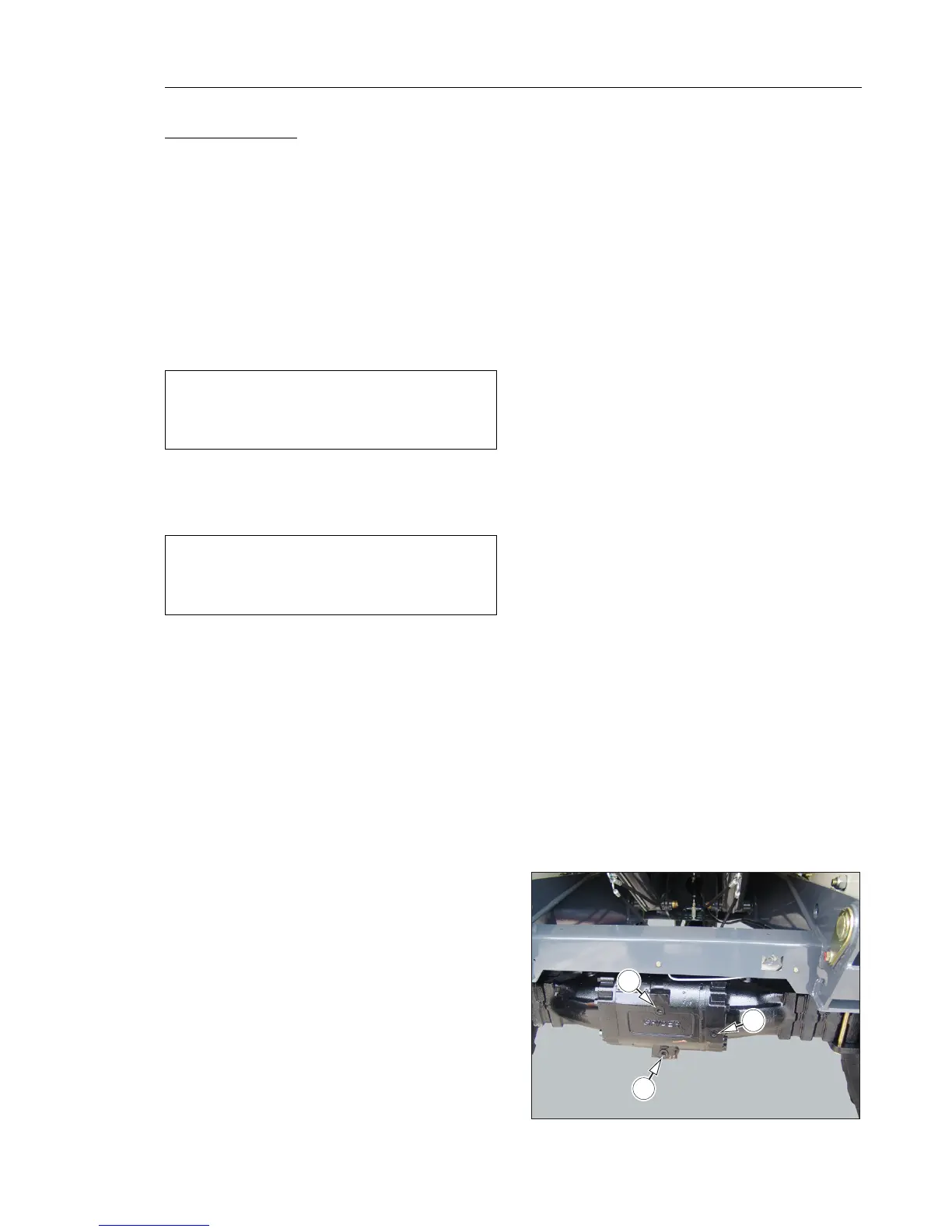

• Position the machine on level ground.

• Clean dirt from around the plugs.

• Remove the oil level plug (B).

• The oil level should be level with the bottom of the oil level

plug hole.

• Add the specified oil, as required, through the filler plug (A)

until the oil begins to run out of oil level plug hole. See

Lubrication Points and Lubricants section for correct oil.

• Refit and tighten the filler plug (A) and level plug (B).

Axle Oil - Changing

• Ensure axle oil is warm - Not Hot, to facilitate draining.

Position the machine on level ground.

• Clean dirt from around drain plugs.

• Place a suitable container of adequate size under the drain

plug (C).

• Remove the filler plug (A) level plug (B) and remove the

drain plug (C). Allow the oil to drain.

• Refit and tighten the drain plug (A).

• Refill the axle through the filler hole (A) until the oil in axle

is level with the bottom of the level plug hole (B). See

Lubrication Points and Lubricants section for correct oil.

• Refit and tighten the filler plug (A) and level plug (B).

b

Always Position Machine on Firm, Level Ground when

Checking Fluid Levels

b

Contaminated Water / Fluids / Oils Must Be Disposed of

Legally

Loading...

Loading...