CUTMASTER 152

Manual 0-4987 3-3 INSTALLATION

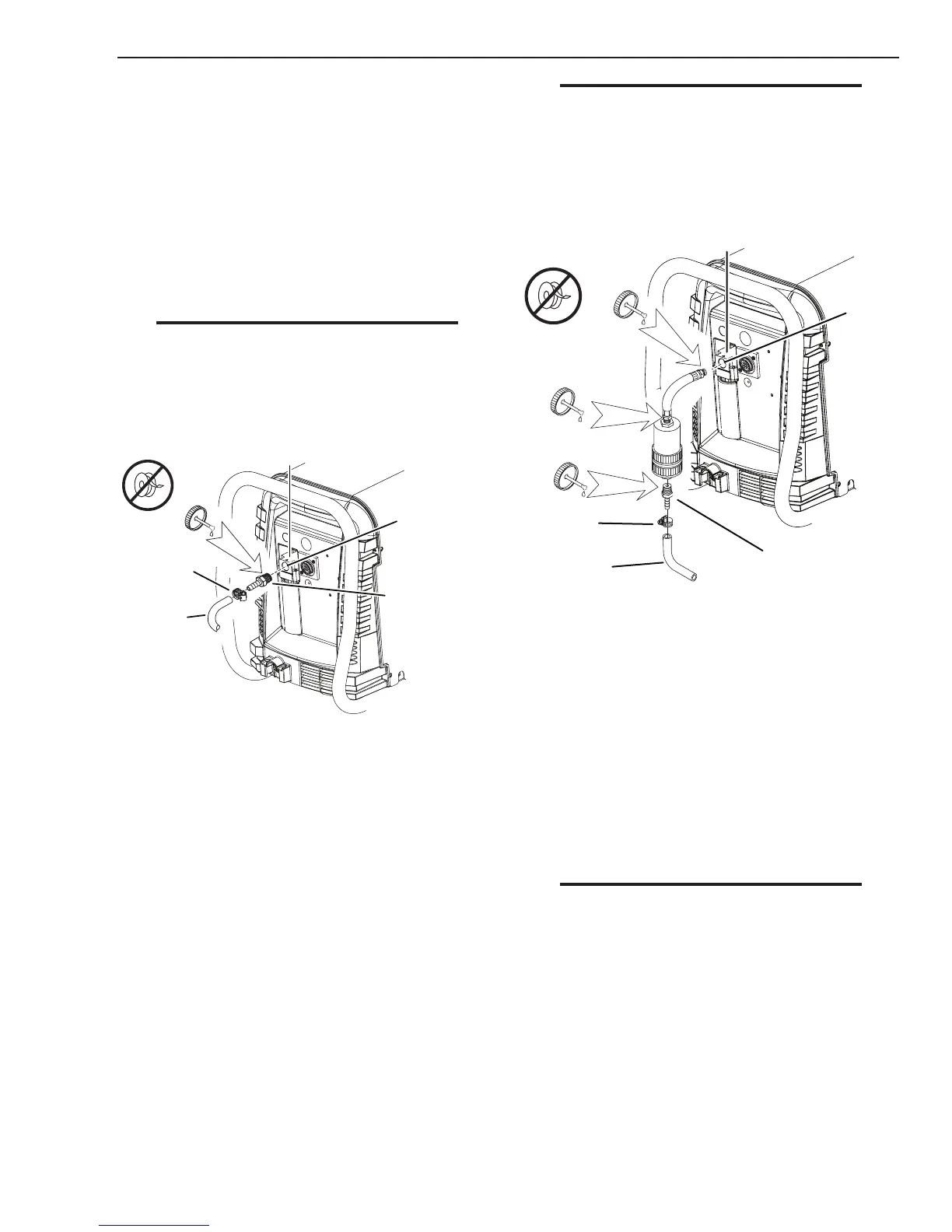

3.04 Gas Connections

Connecting Gas Supply to Unit

The connection is the same for compressed air or

high pressure cylinders. Refer to the following

two subsections if an optional air line lter is to

be installed.

1. Connect the air line to the inlet port. The

illustration shows typical ttings as an

example.

NOTE

For a secure seal, apply thread sealant to the

fitting threads, according to manufacturer's

instructions. Do not use Teflon tape as a thread

sealer, as small particles of the tape may break

off and block the small air passages in the torch.

Art # A-07943

Hose Clamp

Assembly

Inlet Port

Gas Supply

Hose

1/4 NPT or ISO-R

to 1/4” (6mm) Fitting

Air Connection to Inlet Port

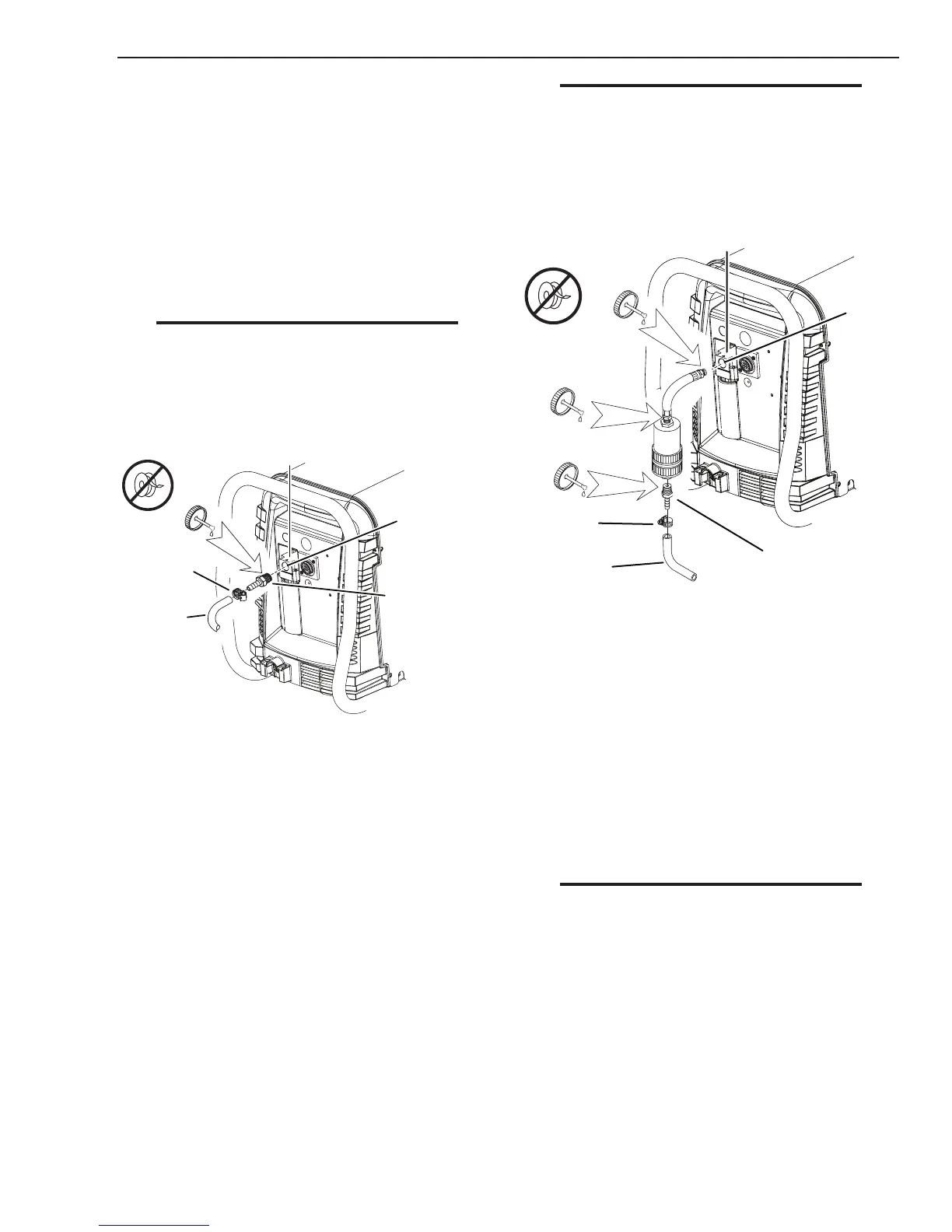

Installing Optional Single - Stage Air Filter

An optional lter kit is recommended for im-

proved ltering with compressed air, to keep

moisture and debris out of the torch.

1. Attach the Single - Stage Filter Hose to the

Inlet Port.

2. Attach the Filter Assembly to the lter

hose.

3. Connect the air line to the Filter. The

illustration shows typical ttings as an

example.

NOTE

For a secure seal, apply thread sealant to the

fitting threads, according to the maker's instruc-

tions. Do Not use Teflon tape as a thread sealer,

as small particles of the tape may break off and

block the small air passages in the torch. Con-

nect as follows:

Art # A-07944

Hose Clamp

1/4 NPT to 1/4"

(6mm) Fitting

Assembly

Inlet Port

Gas Supply

Hose

Optional Single - Stage Filter Installation

Installing Optional Two - Stage Air Filter Kit

This optional two - stage air line lter is also

for use on compressed air shop systems. Filter

removes moisture and contaminants to at least 5

microns.

Connect the air supply as follows:

1. Attach the Two Stage Filter bracket to the

back of the power supply per instructions

supplied with the lter assembly.

NOTE

For a secure seal, apply thread sealant to the fit-

ting threads according to manufacturer's instruc-

tions. Do Not use Teflon tape as a thread sealer

as small particles of the tape may break off and

block the small air passages in the torch.

2. Connect the two stage lter outlet hose to

the inlet port of the Regulator / Filter As-

sembly.

3. Use customer - supplied ttings to connect

the air line to the Filter. A 1/4 NPT to 1/4"

hose barbed tting is shown as an example.

Loading...

Loading...